No-Burr Threading Helps Shop Compete

With the switch from a ground top-notch tool to a pressed Ingersoll threading form tool on one high-volume job, Warren Screw Machine eliminated 2 minutes of hand deburring per part. Not incidentally, the company also lopped 20 seconds per part off the threading cycle.

Automation In A Production Shop

Production turning automation is the beneficiary of increasingly powerful design and application tools. This makes it much easier to create automation that fits the application.

Reestablishing A Name In Bar Feeders

To keep its well known line at the forefront of the minds of those in the market for a bar feeder, this company completely redesigned its product. Features such as a see-through cover and Direct Connect programming through the machine tool's CNC demonstrate the results of this focused effort.

Milling Tools

Iscar is expanding it's Multi-Master line of tools that are designed to allow users to do a variety of milling operations in a single shank. An array of head geometries are currently available to perform ball nose, square shoulder, chamfering and slitting/slotting operations. The easily interchangeable carbide heads provide performance for all of these applications with the added advantage of reduced indexing time.

Shop Sticks With Stick Tooling

Who says we can’t be competitive on simple parts? The secret for making it happen at one Connecticut shop is the combination of modern CNC Swiss-type machines and good old-fashioned “stick” tooling.

酒吧喂食器和工件表面光洁度

Quality surface finish of a part is not only dependent on the turning machine itself, but also on the barstock loading and support system. The bar feed system becomes critical to the surface finish outcome by enabling the turning machine to create the desired finish and/or by protecting the existing finish.

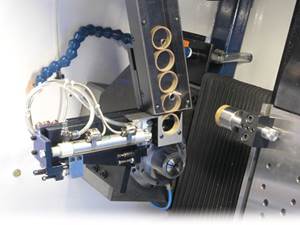

Swiss-Type Machines: More Than Just a Lathe

CNC Swiss-Type machines have more capability built in than ever before. Many of these capabilites can be accessed using attachments that increase the throughput of the machine tool, improve the quality of the work coming off the machine and reduce or eliminate the need for secondary operations even for very complex workpieces.

The Change To Quick-Change Collets

Quick-change collets can improve production times and accuracy while alleviating any change-over issues typically associated with standard collets.

Hold On With Vacuum Clamping

Because of the possibility of workpiece deformation, clamping using three-jaw chucks is not always suitable for final machining. In cases where tight machining tolerances must be upheld, this Danish cutting specialist relies on vacuum clamping technology to hold its parts.

Line Your Spindles, Line Your Pockets

Urethane spindle liners present a viable option to steel to fill the gap between spindle ID and bar OD. They protect both the spindle and bar stock and increase machine performance.

.jpg;maxWidth=300;quality=70)