The Big Step Up

A small shop added two new machines, each of which is more advanced than any of the previous machine tools the company has used. One of the co-owners committed to the work of bringing both of these machines fully into service. Here is the shop’s experience so far.

从Susta储蓄inability

A project aimed at energy-efficient machining delivered production efficiencies, too.

Consistency Is Key to Titanium

An important part of this shop’s successful approach to titanium machining is a toolpath strategy that keeps the load on the cutter constant. Another important element is the way this shop captures and reapplies what it learns about how effective it can be in this metal.

Considerations for Machining Exotics

In manufacturing, the term “exotic” is used to describe materials that display excellent wear characteristics, durability and service life in high heat, extreme cold or corrosive environments.

#metalworkingfluids

90 Cubic Inches Per Minute in Titanium

Mag says its XTi super profiler is designed to remove metal at impressive rates. Its first two machines are are being used for aerospace applications.

Lean from the Beginning

How would you design a new plant if you could begin today? Rolls-Royce Crosspointe is a major manufacturing site that was planned from the outset with the expectation that continuous improvement would always be part of its culture.

#workforcedevelopment

Setup Time Savings from a Long X Axis

Bertsche Engineering developed the X-Flex Center to replace three standard-size machining centers.

The Future of Manufacturing

According to engineers with GE Aviation, the challenges of additive metal manufacturing—serious as they are—are small compared to the promise that this technology holds. How else can you make a plane engine 1,000 pounds lighter?

Cryogenic Machining of 787 Fuselage

Starting early next year, Boeing South Carolina will mill and drill composite fuselage sections for the 787 Dreamliner through cryogenic machining.

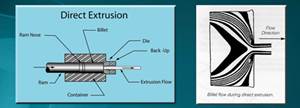

Consistency with Indirect Extrusion

A return to basics, paired with extensive research, proved instrumental in the enhancements of this aluminum rod and bar manufacturer’s product line.