Five-Axis Trimming Of Composites

Here is video of the five-axis motion required to trim a relatively simple composite component.

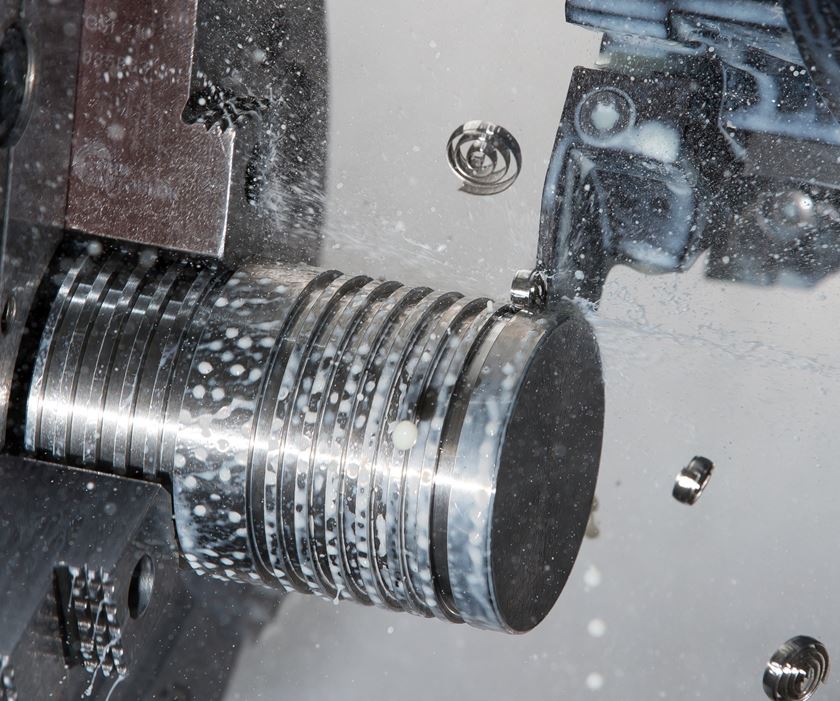

Milling high-performance composites does not make extreme demands on the machining center. A relatively low-cost machine can do the work. The most extreme demand is likely to be the range of five-axis motion required. This video taken at Hydrojet, a Reading, Pennsylvania, shop specializing in machining composites, shows how much five-axis motion is needed to trim a relatively simple composite component. (So that the machine’s doors could be open, this video repeats the machining cycle for a part that has already been trimmed.)

RELATED CONTENT

Consistency with Indirect Extrusion

A return to basics, paired with extensive research, proved instrumental in the enhancements of this aluminum rod and bar manufacturer’s product line.

Single Pass Honing System with Automatic Tool Wear Compensation

Single pass honing, also referred to as diamond bore sizing, is a good way to produce parts economically when the bore is small or has thin-walled members that need to be honed.

Cutting a Micron at a Time

When the task is to remove very small amounts of material, this process may be the answer.

.jpg;width=70;height=70;mode=crop)