United Grinding’s Studer RoboLoad Offers Seamless Part-Loading Automation

Appears in Print as:'RoboLoad Offers Seamless Part-Loading Automation'

这台机器操作不需要编程ledge, enabling better production flexibility and a higher degree of operating comfort.

Edited byAngela Osborne

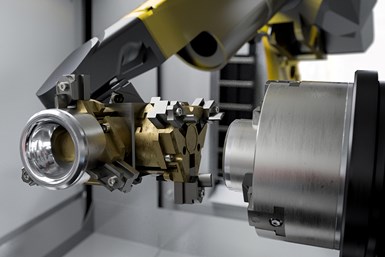

The Studer roboLoad operates without any programming knowledge, enabling better production flexibility and a higher degree of operating comfort. Photo Credit: United Grinding

United Grinding’sStuder RoboLoad system offers manufacturers simple, seamless part-loading automation for CNC radius internal grinding machines such as the Studer S121, S131 and S141.

The company says, until now, loader integration could be intrinsically difficult on these types of machines because of the height of their workheads and associated geometric restrictions. It is said the Studer loader not only meets the geometrical requirements but also has a comparatively small footprint. For more ease of use, it operates without any programming knowledge, enabling better production flexibility and a higher degree of operating comfort.

On the Studer S121, S131 and S141 machines, the automatic B axes swivel in a range from -60 to more than 91 degrees. The RoboLoad offers the capability to exit the machine and give the B axis the freedom to swivel.

As an external loader, theautomation systemmeasures only 59.06" (1.50 m) wide, which is half the width of the machine itself. This saves shopfloor space, while still offering ample room for workpieces, which are manually loaded on six trays — each measuring 42.52" × 12.6" (1,080 mm × 320 mm).

Operators can bring up any grinding program for the workpieces, and the RoboLoad processes them and places each workpiece back in the same place after machining. For operation simplicity, it incorporates a setup wizard developed byWengerwhich requires no programming knowledge from the setter or machine operator. The easy-to-follow steps are graphically presented on a large 19'' intuitive display, the company says.

Specifications include a FANUCM10-iD 10L robot, Siemens simotion control and grippers with quick-change jaws, convertible to a single gripper for parts weighing up to 15.4 lbs (7 kg) or dual gripper for parts weighing up to 6.2 lbs (2.8 kg). Maximum workpiece size is 10.24" (260 mm) in diameter and 0.39"-3.93" (10-100 mm) in length.

RELATED CONTENT

What Is The Best Bar Feed System For Production Turning?

Selecting the right bar feeder can be one of the most important decisions a shop can make. Bar feed systems help improve productivity, throughput and quality, but in order to achieve the most benefit from them it is essential that a bar feed system be matched to the particular needs of the turning operation.

Advantages of Cellular Manufacturing

Manufacturing cells are used to minimize product movement as well as materials, equipment and labor during the manufacturing process. By reducing cycle times and material handling, these cells help shops more easily meet customer demands regarding cost, quality and leadtimes.

The Many Sides of Workholding

Here's a broad look at different ways to approach workholding, from bar feeders to collet chucks to robotics.