SW’s Single-Table Machines Designed for Machining Large Parts

Appears in Print as:'Single-Table Machines Designed for Machining Large Parts'

SW’s BA W08-11 and BA W08-21 can be automated with a variety of solutions, including TopRob which facilitates the loading and unloading of large and heavy workpieces with the aid of robots on platforms or gantries above the machine.

Edited byAngela Osborne

SW’s BA W08-11 was developed for machining aluminum workpieces.

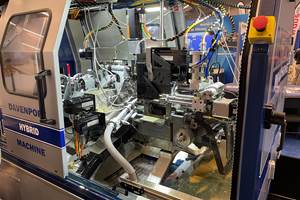

SW’stwo newest single-table machines, the BA W08-11 and BA W08-21, are designed for the precise machining of large workpieces with long cycle times. With one worktable and one or two spindles, thesemachineshave large working areas enabling the high-performance machining of especially large workpieces, including battery trays, turbine blades, gearbox housings, steering knuckles and subframes.

SW’s BA W08-11 was developed for machining aluminum workpieces. The use of linear direct drives enables the machine to have an acceleration of 2 g in the linear axes. It has a 35-kW spindle with up to 17,000 rpm at 80 Nm and HSK-A63 interface. HSK-A80 and HSK-A100 spindles are also available.

The BA W08-11 prototype has a working range of 1,500 mm (X), 1,025 mm (Y) and 660 mm (Z). The interference zone of the A-axis has a diameter of 1,650 mm and a length of 1,830 mm. A space version features a larger interference zone diameter of 1,850 mm and length of 1,980 mm on the A-axis.

SW还开发了英航W08-21, twin-spindle sister model that enables machining of two workpieces at the same time. In this machine, travel of the spindles is 800 mm (X), 1,025 mm (Y) and 660 mm (Z). These specifications apply to the HSK-A63 and HSK-A80 interfaces. In addition to single-table machines with linear direct drives for the machining of non-magnetic materials, SW is also developing single-table machines with proven ball screw drives for the machining of conventional iron, steel or nickel-based materials.

The new models in the BA W08 series can be automated with a variety of solutions, including TopRob which facilitates the loading and unloading of large and heavy workpieces with the aid of robots on platforms or gantries above the machine. Multiple grippers enable the rapid exchange of finished and raw parts. Another option is to load and unload the machines from the front with an SW FloorRob.

RELATED CONTENT

How to Get More Efficient Production from Swiss-Type and Multitasking Machines

SolidCAM for multi-axis Swiss type and multitasking machines provides a very efficient CAM programming process, generating optimal and safe Mill-Turn programs, with dramatically improved milling tool life.

High Speed Spindles For Swiss Machining

This article discusses the use of high-speed spindles in Swiss machining applications. Sufficient rotational speed is necessary to take advantage of tooling materials in small diameter cutters.

Swiss-Type Machines: More Than Just A Lathe

CNC Swiss-Type machines have more capability built in than ever before. Many of these capabilites can be accessed using attachments that increase the throughput of the machine tool, improve the quality of the work coming off the machine and reduce or eliminate the need for secondary operations even for very complex workpieces.