Sumitomo’s SMDT-NAL Replaceable Drill Tip for Machining Aluminum

Appears in Print as:'SMDT-NAL Drill Tip for Machining Aluminum'

Sumitomo adds SMDT-NAL Drill Tip to its lineup of high-quality, high-efficiency products for drilling aluminum.

Edited byAngela Osborne

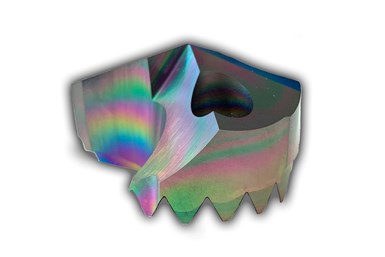

Sumitomo’s SMDT-NAL drill tips feature a diamond-like carbon DLC ‘Aurora’ coating which is designed for high-efficiency machining of aluminum alloys and nonferrous materials. Photo Credit: Sumitomo

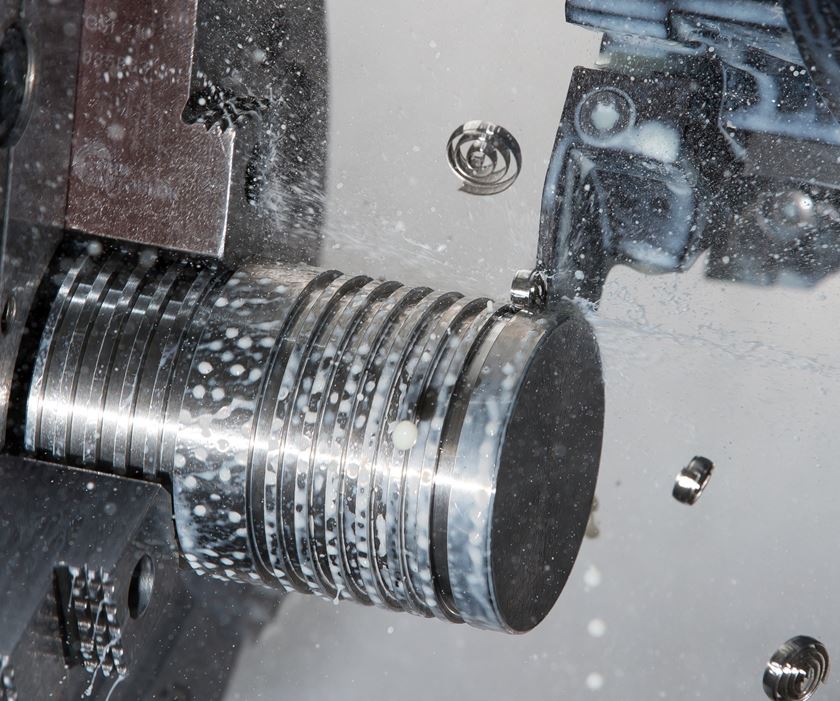

Sumitomois expanding its existing SMD replaceable tip drilling lineup with the SMDT-NAL drill tips, which feature a diamond-like carbon DLC Aurora coating designed for high-efficiency machining of aluminum alloys and nonferrous materials.

SMD holders include deep holedrillingup to 12XD standard. The SMDT drill tip product lineup offers diameters ranging from fractional sizes15/3211/4to suit a variety of applications.

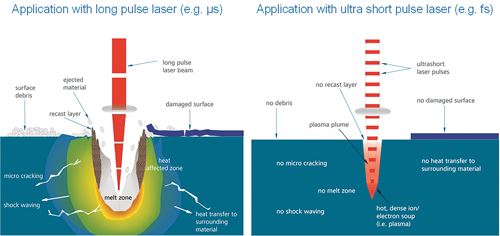

The DLC Aurora coating is an amorphous film whose main composition is carbon featuring lubricity and chemical stability. It is a hard thin film that features high hardness, superior tribology properties and excellent adhesion resistance, the company says. DLC films have been used to reduce fuel consumption of automobiles by reducing friction loss and are also used as a coating of cutting tools for aluminum alloys that have been widely used for aerospace and automobile weight reduction.

Read: Sumitomo Turning Grade for Enhanced Chip Control

Sumitomo’s family of tools for aluminum holemaking include the replaceable tip drilling (SMDT-NAL), solid carbide drilling with DLC coating (MDW-NHGS) and DLC coated indexable inserts (WDX). Key product benefits include an ultra smooth coating surface which results in stable chip evacuation; aluminum welding resistance for excellent surface finish; and hardness of 60GPa for superior abrasion resistance, the company says.

Other advantages include increased penetration rates (feed rate/drill diameter = penetration rate) due to a low friction coefficient. All these benefits are said to enable customers to machine with 2 times to 3 times higher feed rates than uncoated drills, thereby reducing cycle time and cost per unit (CPU).

RELATED CONTENT

A Guide to Insert Coating Processes and Materials

Few materials have had a greater impact on our economy and industrialized culture than cemented tungsten carbide.

Skiving Long, Slender Parts with Tight Tolerances

Here's a look at one of the oldest and most efficient methods of screw machine production for parts that are long and slender, with close-diameter tolerances and finishes, or parts that require truly spherical radii.

Inventory Control Systems For The Shop

An ongoing effort towards more efficient operations drove this shop to take a closer look at indirect material usage, subsequently leading to implementation of a new system for tracking toolroom inventory.