山特维克可乐满OptiThreading软件支持Controlled Chip Breaking

Appears in Print as:'OptiThreading Software Enables Controlled Chip Breaking'

Manufacturers can use the OptiThreading software module to enable controlled chip breaking in thread turning applications.

Edited byAngela Osborne

The OptiThreading software module for thread turning is said to help overcome the risk of chip jams and associated downtime.

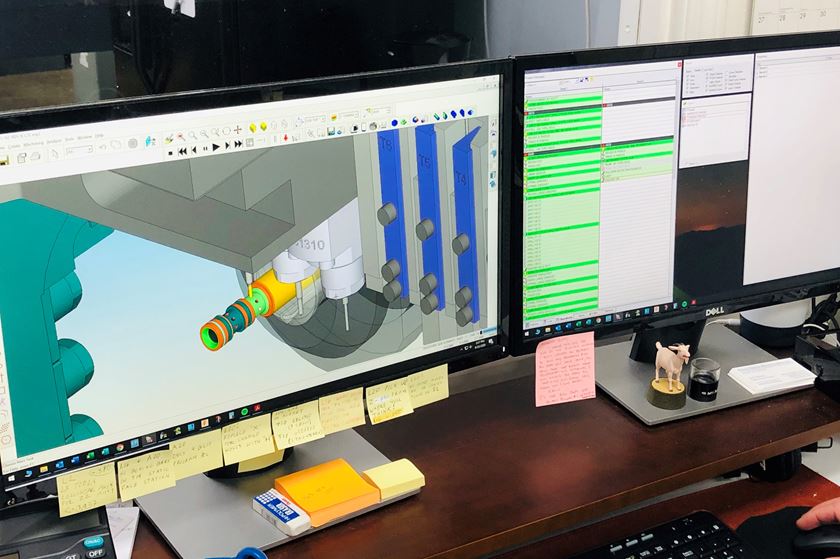

Sandvik Coromant’sOptiThreading is a software module located within its existing Coroplus Tool Path software. It is designed to help manufacturers overcome one of the most significant issues within thread turning — the risk of chip jams and their associated downtime. Using the module, manufacturers are said to use this machining method to enable controlled chip breaking in thread turning applications.

CoroPlus Tool Path software offers programming support for external and internalthread turning operations. The software generates NC codes based on cutting data parameters to secure the correct number of passes with evenly distributed cutting forces for optimal productivity, tool life and process security, the company says.

OptiThreading is said to enhance the software. A common problem in thread turning is that chips coil around robots, chucks, tools and components. The chips can also get caught in conveyors, causing damage and equipment downtime. Successful chip control can be the key to good component quality when thread turning.

Read: Sandvik Coromant Appoints New Members to Management

模块的软件可以作为潜艇的一部分cription to the CoroPlus Tool Path and was developed specifically for CoroThread 266 tools and inserts.

CoroPlus Tool Path helps users develop optimized OptiThreading tool paths that specifically overcome the challenge of chip control. According to the company, this is achieved by offering tool paths that deliver controlled, oscillating movements for interrupted cuts that go in and out of the cut on all passes except the last one.

RELATED CONTENT

The Long And Short Of Bar Feeder Selection

For many shops, the decision comes down to a 4- or 12-foot-capacity magazine-style bar feeder. Here are some guidelines for choosing between them.

Thread Whirling Basics

The rapidly increasing demand for high-value threaded parts with exceptionally high length-to-diameter ratios has created a lot of interest in thread whirling technology among American shops and manufacturers.

Broaching On A Lathe

Producing a keyway, spline or similar longitudinal feature on a turned part usually necessitates an additional, time-consuming, secondary operation on a broaching or slotting machine. That means moving the part to and from a secondary operation, an extra setup, additional labor and hourly machine costs and all of the other headaches that go with secondary operations.