Kurt, Absolute Machine Tools Develop Automation Package

Appears in Print as:'Companies Collaborate on Turnkey Automation Package'

Automation package designed to simplify integrating automation into a shop’s production processes includes a Mitsubishi LoadMate Plus, Kurt 3600A pneumatic vise and Kurt RV36 robotic gripper working in tandem with a Tongtai VP-10 mass-production, high-speed vertical machining center.

Edited byAngela Osborne

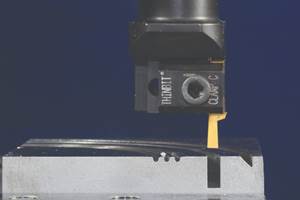

The automation package is designed to be an easy way to integrate automation into a shop’s production processes. Photo Credit: Kurt Workholding

Kurt Workholdingand绝对的机床have collaborated on a turnkeyautomationpackage for shops which features a Mitsubishi LoadMate Plus, Kurt 3600A pneumatic vise and Kurt RV36 robotic gripper working in tandem with aTongtaiVP-10 mass-production, high-speed verticalmachining center.

The Mitsubishi LoadMate Plus is virtually a “plug and play” machine tending robotic cell, the company says. Along with a Kurt RV36 Gripper and automation-ready pneumatic and hydraulic workholding products, the package is designed to be an easy way to integrate automation into a shop’s production processes.

The VP-10 has X-, Y-, and Z-axis travels of 40.2" × 20.1" × 23.6" (1021 mm × 510 mm × 600 mm). High power servomotors produce 1,890 ipm (48 m/min) in X and Y, and 1,417 ipm (36 m/min) in Z. Acceleration in X, Y, and Z is 1.18G, 1.0G, 0.7G, respectively. It features a standard 10K-rpm, 20-hp direct drive spindle, and toolchanger that can hold as many as 30 tools. The standard Mitsubishi M80A control features a 10.4" (265 mm) touchscreen.

The package includes the Kurt 3600A VersatileLock pneumatic vise and RV36 robotic gripper. Designed for precision clamping, the vise’s “pull-type” action and AngLock jaws reduce stationary jaw deflection by at least 80%, the company says. A one-piece body and stationary jaw design is said to reduce weight and increase strength while providing 0.0005 clamping repeatability. Pneumatically actuated steel or aluminum finger configurations are available and attach to the vise using pull studs for changeability with a maximum payload of 50 lbs.

Absolute Machine Tool customers can purchase Kurt vises and RV36 grippers as part of a package with the VP-10 and LoadMate Plus. The LoadMate Plus also packages as a stand-alone robot cell using an RV-8 Mitsubishi robot.

RELATED CONTENT

Hard Turning as an Alternative to Grinding

Hard turning can be a cost effective alternative for shops looking to streamline part processing.

Endworking Enhances Shaft Manufacturing Process

Because endworking is often considered only as a preliminary step for shaft work typical of the automotive industry, potential productivity gains are being passed by. Newer technology has enabled these machines to handle far more applications.

Swiss-Type Machines: More Than Just A Lathe

CNC Swiss-Type machines have more capability built in than ever before. Many of these capabilites can be accessed using attachments that increase the throughput of the machine tool, improve the quality of the work coming off the machine and reduce or eliminate the need for secondary operations even for very complex workpieces.