Carr Lane Manufacturing Part Loading Solution

Appears in Print as:'Part Loading Solution for Precision Placement'

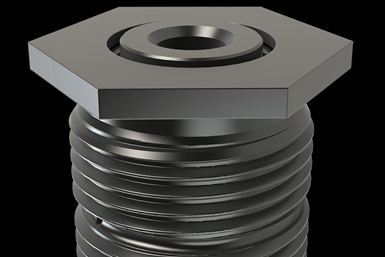

Eastec 2021: Carr Lane's buttons are designed to seal off airflow and increase the overall pressure of the system.

Edited by

Carr Lane Manufacturing’s Air Rest Buttons (ARB) use pneumatic position control to properly detect workpiece loading in a fixture, the company says. Consisting of a threaded body installed in a fixture, these units hold a precision floating plunger. Once proper placement of a workpiece on the ARB assembly occurs, the plunger fully retracts into the body, which is designed to seal off airflow and increase the system’s overall pressure. The pressure value can be read using an analog or digital pressure system.

The plunger accepts Carr Lane Manufacturing standard press-fit type rest buttons and is available in three diameters.

RELATED CONTENT

长和短Of Bar Feeder Selection

For many shops, the decision comes down to a 4- or 12-foot-capacity magazine-style bar feeder. Here are some guidelines for choosing between them.

Simplifying Machine Load/Unload Automation

Today, lower part volumes and frequent change-over are changing the offerings of some automation integrators. Standard, off-the-shelf components are being engineered to work together in a large variety of applications and, in some cases, are even portable so they can be moved from machine tool to machine tool.

Robots as Precision Machine Tools

To remain competitive, high-end manufacturing companies are looking for accurate, reliable and maintenance-free machine tools offering fast change-over, programming and setup. Industrial robot technology could provide an excellent base for machining because it is flexible and affordable.