Two Companies Collaborate on Touch-Based Programming Technology Product

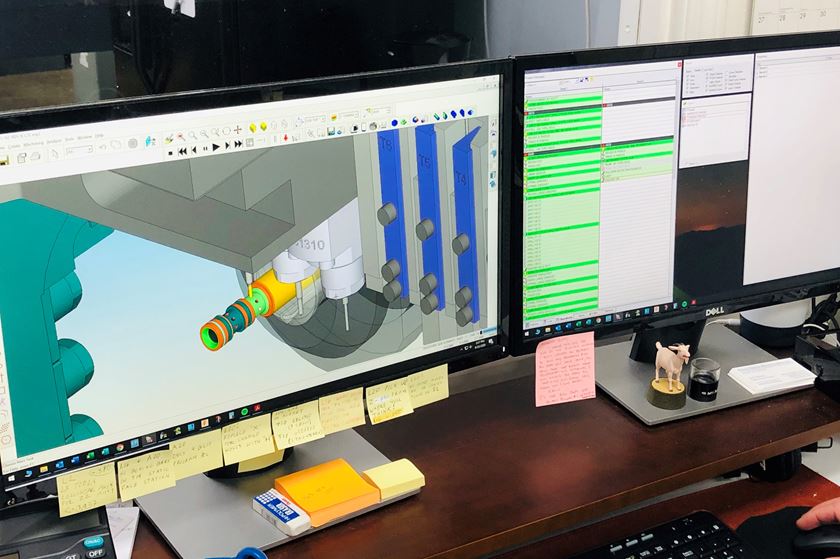

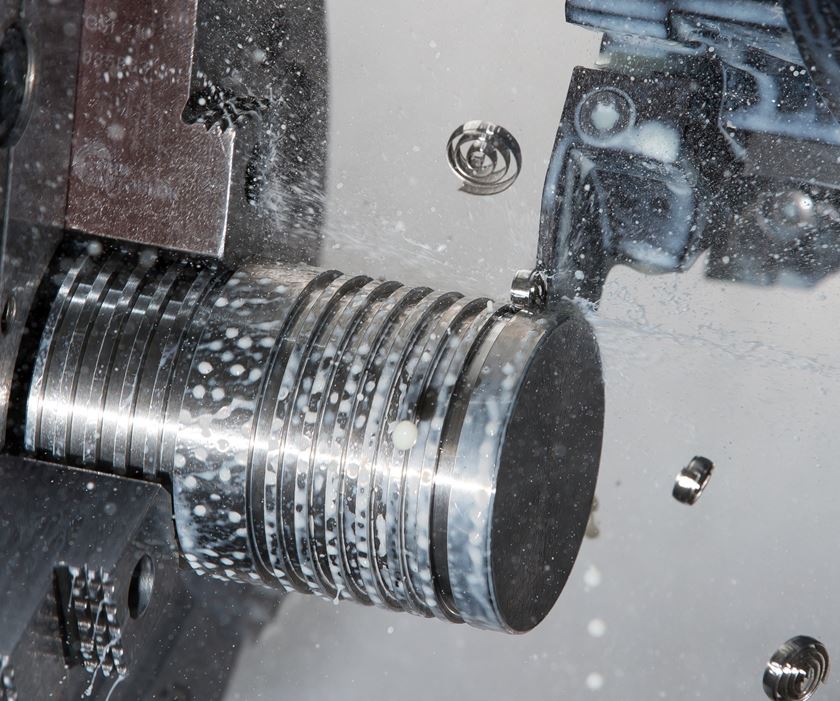

ModuleWorks, a supplier of CAD/CAM software components for machining and simulation, and Sandvik Machining Solutions are collaborating on the development of touch-based programming technology that enables users to create and simulate CNC programs.

Edited byLori Beckman

ModuleWorks, a supplier of CAD/CAM software components for machining and simulation, and Sandvik Machining Solutions are collaborating on the development of touch-based programming technology that enables users to quickly create and simulate CNC programs.

The new application is called Prism and is being developed byApplied Manufacturing Technologies, a division of Sandvik Machining Solutions. Applied Manufacturing Technologies is combining the manufacturing know-how of Sandvik Machining Solutions with the latest ModuleWorks toolpath generation and simulation technology to empower engineers and operators with the new shop floor programming concept that increases productivity and machine uptime.

“As machining becomes more and more sophisticated, the industry needs intelligent solutions that assist engineers and operators as much as possible. Around half of the parts produced today are notprogrammedusing CAD/CAM software, but are insteadprogrammedon the shop floor, and we aim to simplify this process”, saysYavuzMurtezaoglu, managing director ofModuleWorks.

For more information about Prism, visit makewithprism.com