Phillips Federal Adds Bel Air Finishing Technology

Bel Air Finishing's post processing technologies will support Phillips' Public Private Partnership, providing training for finishing for 3D printing.

Phillips Federal(Hanover, Md.), a division of Phillips Corporation, has added Bel Air Finishing’s post processing technologies to support its Public Private Partnership (P3) and additive manufacturing programs at Rock Island Arsenal (RIA).

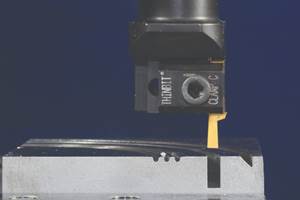

Bel Air and Philips have combined to install a cell for post processing of all types of metal and plastic additive manufactured components. The operational system will be used as a training facility for U.S. Army and private contractors involved in 3D printing around the world.

The Bel Air team looks forward to working with Phillips to teach the various technologies of post processing for additive manufacturing. The training facility aims to make printing more efficient and improve quality.

The cell includes automated build removal, surface grinding, polishing, cleaning and its own closed loop water feed system. Bel Air personnel will bring their 50+ years of experience, joining Phillips to be part of numerous scheduled training workshop presentations. Get more informationhere.