MxD to Develop Cybersecurity Workforce Development Program with Siemens Grant

The program is being piloted at two high schools in the Chicago metro area, with plans to scale to other schools over the next few years.

Edited by

MxD,以前UI实验室,与成矿前进ding a workforce development program for cybersecurity in manufacturing, underwritten by a $1.25 million grant from the Siemens Foundation. The grant will fund the development and implementation of the initiative as part of MxD’s workforce strategy, MxD Learn.

With an increasing number of cyber threats to operations, manufacturers in the United States – 98 percent of which are small and medium size – need qualified workers to protect against cyber-attacks as they aim to stay competitive and invest in modern technologies to digitize operations, MxD says. MxD Learn is expected to develop a taxonomy of high-demand manufacturing cybersecurity jobs and skills, create curriculum and training partnerships, and provide hands-on training through apprenticeships.

A portion of the grant will support a digital manufacturing laboratory at Waukegan High School, a Title 1 school in Chicago, where MxD has previously supported curriculum development. In addition, MxD Learn will replicate the program at a second high school in Chicago, creating a template for further expansion. According to MxD, these programs represent the first steps toward scaling the high school program in more locations over the next few years.

MxD Learn will kick off in Fall 2019 with initial activities planned over three years as part of the Siemens Foundation’s SPARKS initiative, which supports STEM training programs for advanced manufacturing and other industries.

RELATED CONTENT

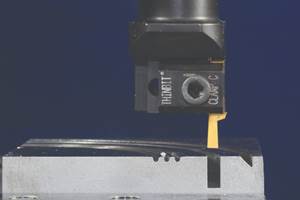

Broken Tool Detection In Machining And Turning Centers

Renishaw's TRS2 broken tool detection system uses a "one-box," single-head design to recognize tool reflections, bringing precise, in-cycle laser monitoring to machining centers and other machine tools.

A Swiss Shop’s Next Generation

The shallow talent pool of available skilled machinists can be an even bigger obstacle to the shop that is rapidly growing. Perhaps the best solution is to attack the problem from within.

Gaging Is Baseless Without Standards

Applying gaging standards consistently is the key to quality parts and products.