生产体积磨练的原型

Here's a machine designed to meet a variety of honing needs. It features all-digital, servo-stroke honing for volumes ranging from prototype to high production.

The honing process continues to grow in relevance as performance requirements increase for such components as turbochargers, gears, fuel systems and valves. Honing can provide the higher accuracies that these systems require, but it’s important to match the application requirements with the appropriate honing process—single-pass or multi-stroke. More information about determining which process is more suitable for a given application can be found in the article, “Single-Pass Versus Multi-Stroke: The Ins and Outs of Honing.”

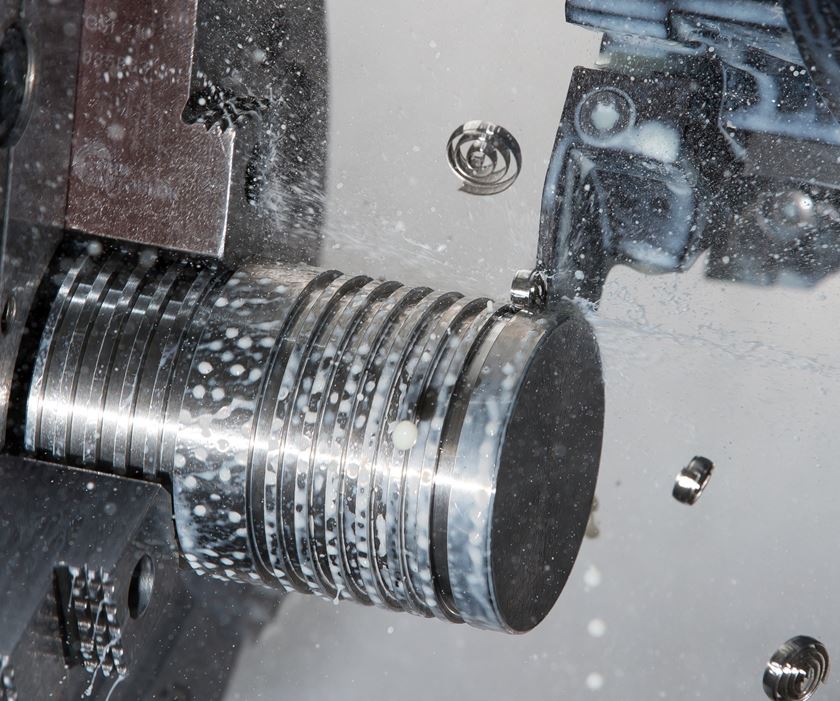

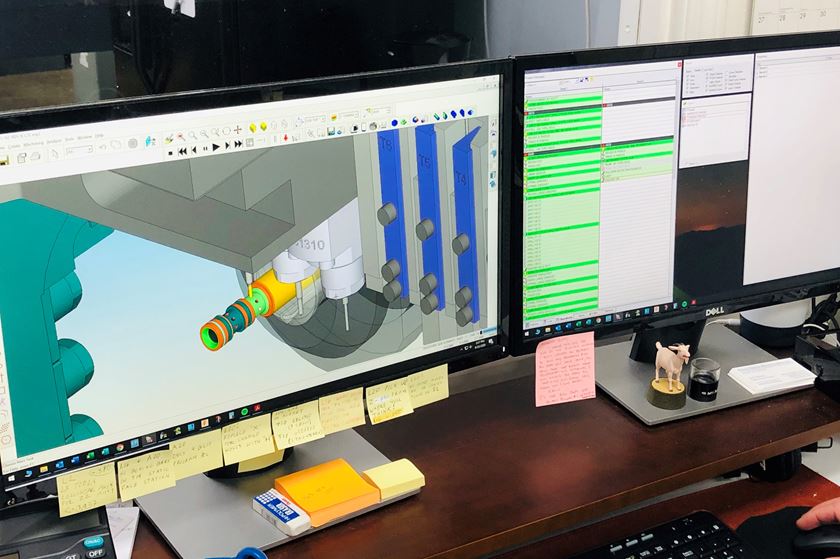

To meet a variety of honing needs, Sunnen Products Company has recently unveiled itsSH-4000系统, which features all-digital, servo-stroke honing for volumes ranging from prototype to high production. Designed for faster, operator-friendly setups, this power-stroked honing machine merges a Siemens touchscreen PLC and digital-servo drives with a servo-hybrid tool feed system and a clear adjustable guard/light curtain for faster, operator-friendly setups. Handling diameters from 1.5 mm to 102 mm (0.060 inch to 6.50 inch), it can process a variety of part sizes, configurations and materials. Spindle speed is infinitely adjustable from 200 to 3,000 rpm with stroke rates of 10 to 550 SPM.

With 45 percent fewer parts than its mechanical predecessors, the SH-4000 introduces digital-servo tool feed and cutting pressure control for consistent, predictable performance throughout the pressure range. Cutting pressure can be adjusted in 4.5-N (1-lbf) increments to a maximum of 2,224 N (500 lbf)—twice that of earlier models. The digital system is designed for effective feed control at low pressures for improved honing results with small-diameter parts. The higher cutting pressure, plus two-step honing capability, ensures short cycle times. Two-step honing allows high stock removal coupled with a precise finish step, all in one operation. In addition, the tool feed system includes 20 mm (0.79 inch) additional travel for increased diameter range when using high production MMT tooling.

Read: Making Tribological Improvements to Bore Surfaces

The servo ballscrew stroker is designed to offer the precision and repeatability necessary for honing in blind bores, while a longer stroke length of 400 mm (15.75 inches) allows the machine to take on deeper bores. The machine's stroking system can be controlled with a joystick on the operator station.

The Siemens 225-mm (9-inch) touchscreen control features infinite part program storage and intuitive setup and run screens. A new digital honing indicator is user-configurable. Standard control features include saved setups, zero shutoff, stone wear compensation, feed speed regulation (stone saver), two-step feed, spindle reverse, speed changes while in cycle, inch/metric selectable units, system diagnostics, cycle dwell, in-process short stroking, and 13 operator languages.