Making it in America

For years, I’ve used the maxim “Showing up is 80 percent of the job.” Recently, I was able to “show up” at the workholding manufacturer Hainbuch’s headquarters in Marbach, Germany. We were hosted with a brief presentation by managing director, Sylvia Rall, a third generation owner of the business.

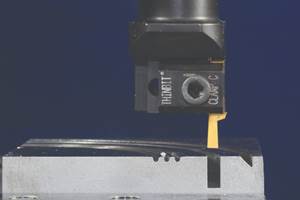

In the past, I’ve worked with theHainbuchU.S. operation in Germantown, Wisconsin, on some articles forProduction Machiningand enjoyed the exercise. In fact, we are planning an article on workholding in our upcoming August issue.

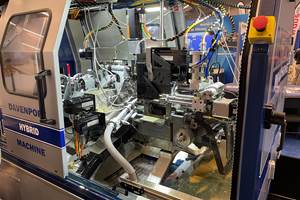

But in addition to making very good workholding equipment, the company’s commitment to the U.S. market, while not unique, is unusual. Last year, it opened a new 14,000-square-foot manufacturing and engineering facility in Wisconsin.

This year, it plans to begin manufacturing some products here. The goal is to reach full production status of all the company’s components in a few years. Investments in new milling, turning and grinding machines reflect this commitment.

Also, having the capability to make products here allows the flexibility to provide inch or metric specifications. Previously, an order for inch specs would become a special in the metric German factory. We all know what that means.

Having the capability to make inch as standard is good for everybody. I’m looking forward to watching the capability develop for this manufacturing enterprise. Hainbuch is not just selling in the states; it is making things here, too. Clickhereto learn more.