保持清洁和不锈钢

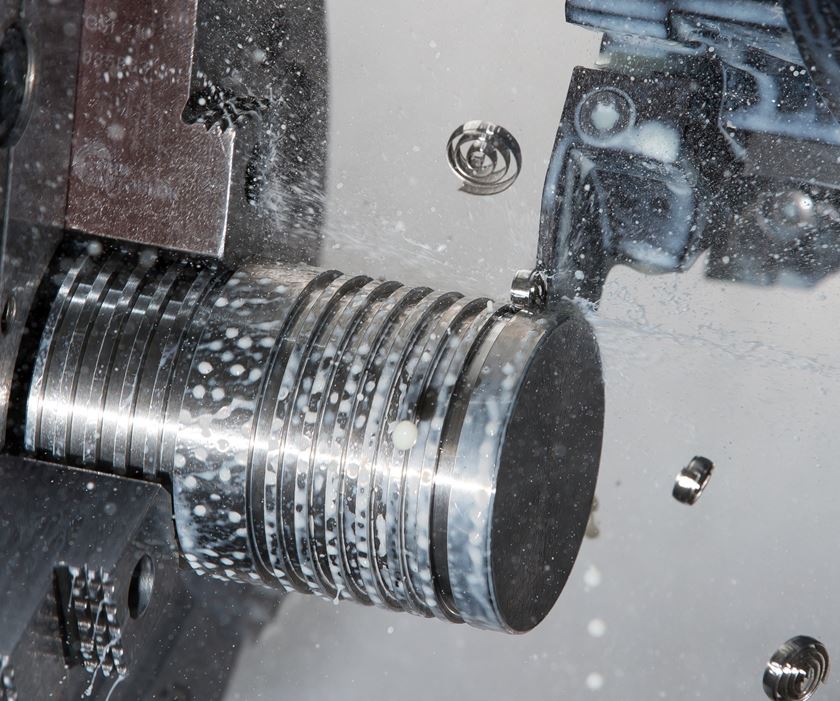

并不多人将反对,零件的清洁度已成为精密零件制造中的决定性质量标准。因此,公司投资金钱和时间来实现客户所需的清洁度规范。

但一旦零件离开机器,就会有防止的风险,由灰尘,微小的颗粒和其他可以在生产环境的空气中找到的东西引起的。另一种危险是生锈的,至少对于由易腐蚀的材料制成的部件,例如钢和铸铁。在达到最终目的地之前思考距离距离距离距离,空气或大海。它们在一个位置制造,然后在例如,热处理店或作业商店涂布机上运输,进一步发布到装配厂。他们经常从一个大陆到另一个大陆的旅行成千上万英里。

To prevent parts from recontamination, encapsulate or cover the unloading area of the cleaning machine. This helps keep cleaned parts clean when packaging and storage is performed in a “clean zone”—an area where no grinding dust and particulates are stirred up.

然后,即使运输容器仅用于将清洁部件从一个加工步骤携带到接下来,它们也不会永远保持清洁。他们也应该经常清洁。各个加工步骤之间的储存时间有助于保持零件清洁和无腐蚀。然而,由于不能始终确保这一点,临时腐蚀保护已成为零件制造的一部分和地块,以及旅行或长期零件储存不可或缺。

通常,将部件放入盒子中并浇注过滤器的过程用于长期零件储存。虽然这种方法很容易快速,但它无效。该油主要保护外表面积,并没有到达内部区域,尤其是具有复杂几何形状的零件。包括在清洁过程中的防腐剂的应用更有效和保护。在这种情况下,与清洁介质一样,它到达部件的外部和内部区域。

Short-term corrosion protection for several hours or days is often carried out in aqueous cleaning systems with a water-based cleaning agent containing amines. In case a longer protection time is required, a separate passivation bath can be employed. Depending on the amine and concentration, a protection period of several weeks can be achieved. Emulsified oils are also used for temporary aqueous corrosion protection. These can prolong the protection time for months. With these substances, the protective layer on the parts surface is created from a two-phase system (water and oil). This can lead to non-homogenous protective films and spot development.

在过去几年中,我注意到的趋势是在完全封闭的真空溶剂清洁系统中进行腐蚀保护,用油,润滑脂或蜡,它们完全溶于溶剂。然后,溶剂清洁系统配备有额外的罐,仅用于腐蚀保护过程。该罐含有溶剂,例如烃,改性醇或全氯乙烯,以及所需量的腐蚀保护介质。清洁部件后,机器的工作室用腐蚀保护罐充斥着介质。与清洁过程一样,达到零件的所有区域。

在随后的真空干燥过程中,溶剂被输送回腐蚀保护槽,同时保护膜保留在部分表面上。有时,溶剂系统仅用于水性清洁过程之后的腐蚀保护,例如,在水性系统中的热量去毛刺后的零件清洗后,其次用一个罐中的溶剂系统中的腐蚀保护步骤。可实现的保护时间为几周或数月,甚至多年来,取决于媒体浓度。

The fact that this corrosion protection method is fully automated, environmentally sound and is an easy process that is homogenous, completely closed and leaves a dry layer on the part’s surface might be why it is increasingly popular.

这项工作不仅通过实现所需的清洁而完成。此清洁度也必须保持在零件到达最终目的地之前。

RELATED CONTENT

Ultrasonic Cleaning for Large Lots of Small Parts

Machining operations such as turning, milling, drilling and grinding leave traces of contaminants behind on workpieces. Ultrasonic cleaning allows for the removal of coolant, chips, polishing paste and other residue in a quick, reliable and economical manner.

清洁度合规对于汽车供应商至关重要

虽然不是电动车ery shop has been affected by cleanliness specifications, many suppliers to automotive OEMs are already complying with stringent cleanliness standards. In Ford Motor Co.’s case, it has created its own cleanliness standards in order to save money and credibility.

基本的含水清洁过程和选择标准

Parts cleaning, like most metalworking processes, is experiencing ever tightening specifications. Shops must continuously evaluate whether to clean parts in-house or use a supplier. This article looks at current aqueous cleaning processes and suggests criteria for the make or buy decision.