Agitation is an Effective Way to Clean Parts

当我使用激动以摆脱废物时,日常生活中存在相当多的情况:摇动桌布或洗碗。当涉及工业部件清洁时,它的某种方式也是如此。

无论我想减肥,获得清晰的心灵还是只是保持健康,我的首选方式就是搬家,比如去散步,游泳或做体操。考虑到这一点,我意识到日常生活中也有相当多的其他情况,当我用搅拌来摆脱废物:摇动桌布或洗碗。当涉及到工业部件清洁时,它有一些方式,同样运动也有助于做一个良好且经济高效的工作。当我记得我在很多年前开始参与工业部件时,我记得我所吸取的东西的显而易见。

有四种因素影响湿化学清洁过程的有效性:化学,温度,时间和机械能。它们是相互依存的因素。在大多数情况下,增加温度将增强化学的溶剂力量。还增加一些机械能有助于更容易地打破污染和表面之间的粘合力,这将导致循环时间较短,从而导致更有效的清洁过程。根据该过程是浸入式清洁还是作为喷雾清洁应用,有几种方法可以引入机械力。

A simple method of applying mechanical energy to immersion cleaning procedures is to move the parts through the cleaning liquid by vertical agitation. The repeated up and down motion is effective in cleaning simple parts, such as workpieces without blind holes, undercuts and/or drill holes.

另一种类型的部件搅拌,其用于封闭机中的水性和溶剂清洁工艺,用于旋转或旋转部件。在这种情况下,工件通常在篮子中堆叠或堆积。为了避免通过部件部分或篮子篮子接触的工件损坏,可以将篮子放在篮筐中作为中间层。

更有效的是加压流量清洁程序,也称为注入洪水洗涤过程。清洁篮也与清洁液一起淹没并通常转动。同时,泵将流体抽出清洁浴,随后通过位于填充水平下方的喷嘴将其注入浴中。这导致强大的电流,在工件上方和围绕工件上清洗并从表面,盲孔,空腔和凹槽中移除污染物。

这种增加机械能方法的优点是其多功能性。加压流动清洁中的喷射系统不必调整以靶向每个特定部件,因此它为各种形状和尺寸的部分提供了良好的清洁度。

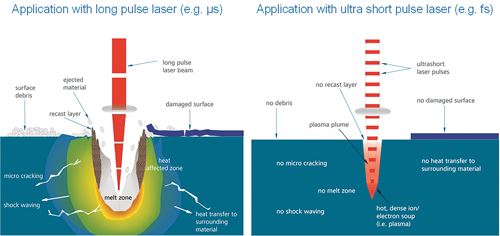

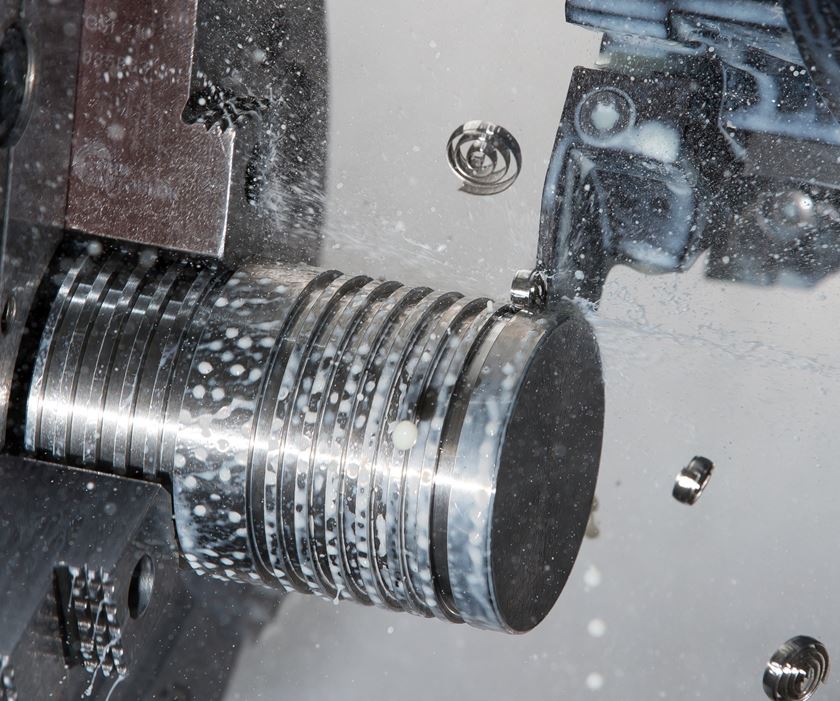

This is also the case with ultrasonic cleaning, which is often used for cleaning machined parts. Here, the mechanical energy is based on the physical principle of cavitation: An ultrasonic generator emits electrical signals at a certain frequency, which are then transferred to the liquid as ultrasound waves via a transducer. The sonic pressure is characterized by interaction of underpressure and overpressure. As a result of the high intensity, microscopic bubbles form in the underpressure phases, which then implode in the subsequent overpressure phase, releasing shock waves with considerable energy densities. This also triggers microflows in the liquid, which remove film-like and particulate contaminants from the components to be cleaned, even for workpieces with complex geometry.

在喷雾清洁过程中,污染通过清洁介质部分溶解或乳化 - 通常是水性试剂 - 并通过喷射射流的动能部分地洗脱。因此,这里的机械能由将培养基喷射到待清洁表面上的压力来产生。根据应用,工作压力可以高达25巴(约360 psi)。高压应用,其范围从150巴(2,175 PSI)高达2,000多个BAR(29,000 psi),可以在一步中进行清洁和去毛刺。喷嘴的形状和布置对清洁结果具有决定性的影响。可能有必要移动清洁和/或喷嘴,以确保均匀清洁所有工件。

In real life, one might take a walk to free his mind or do a hard workout to improve his shape, all depending on constitution and aim. The same applies for cleaning processes: contamination, cleanliness requirements, part geometry and other factors will define the right process choice.

RELATED CONTENT

基本的含水清洁过程和选择标准

Parts cleaning, like most metalworking processes, is experiencing ever tightening specifications. Shops must continuously evaluate whether to clean parts in-house or use a supplier. This article looks at current aqueous cleaning processes and suggests criteria for the make or buy decision.

用溶剂清洁和腐蚀保护

以有效和可持续的方式保护零件防锈。

航空航天水性清洁

A turbine manufacturing plant phases out an obsolete vapor degreasing system, making the change to aqueous-based cleaning.