The Software Side of Cutting Tools

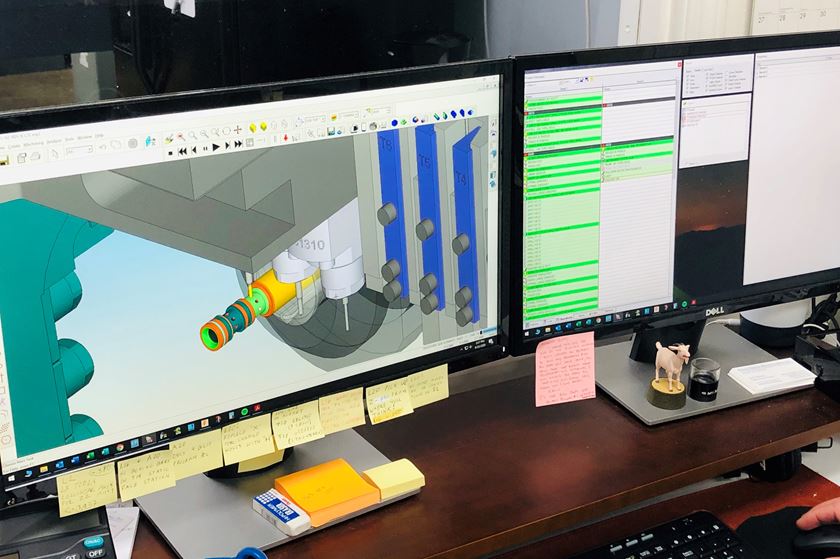

In CNC machining, there is a significant amount of technology that can be applied prior to making the first chip. This article looks at software enhancement tools that can help optimize the cutting operation before hitting cycle start.

Shops make money making chips. The longer a cutting tool is in the cut, the more value is added to the workpiece and therefore the more efficient and profitable the machining operation is.

In CNC machining, there is a significant amount of technology that can be applied prior to making the first chip. The article, “Consider the Software Side of Cutting Tools,” looks at software enhancement tools that can help optimize the cutting operation before hitting cycle start.

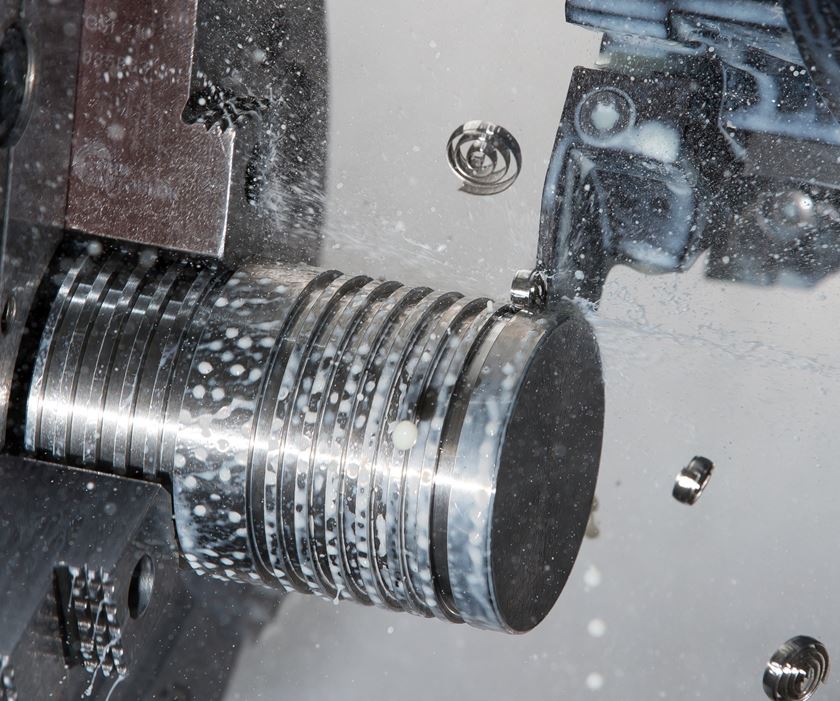

One such enhancement technology is called dynamic motion, and it is available fromMastercamfor use in its CAM package. It provides the ability to adjust cutter path constantly to ensure the programmed feed-per-tooth is maintained during machining. It can significantly impact the cycle time in a positive way to improve machining efficiency.

The article also looks at work that Mastercam did with Sandvik in the development of its Prime Turning process for use in bi-directional turning operations that can double the metal removal capability for turning operations. Read the articlehere.