Accommodating Unleaded Brass

通过识别和适应无铅黄铜的缺乏铅,不同的导热率,芯片形成的差异以及需要增加较重的饲料而不是更高速度的工具,您的商店也可以成功地从这些更新的零件中制作零件,更具挑战性的成绩。

Unleaded brasses are not necessarily harder to run than leaded brass. They are just different. By recognizing and accommodating for their lack of lead, and the different thermal conductivity, differences in chip forming, and the need to up-tool for heavier feeds rather than higher speeds, your shop can also be successful at making parts from these newer, more challenging grades.

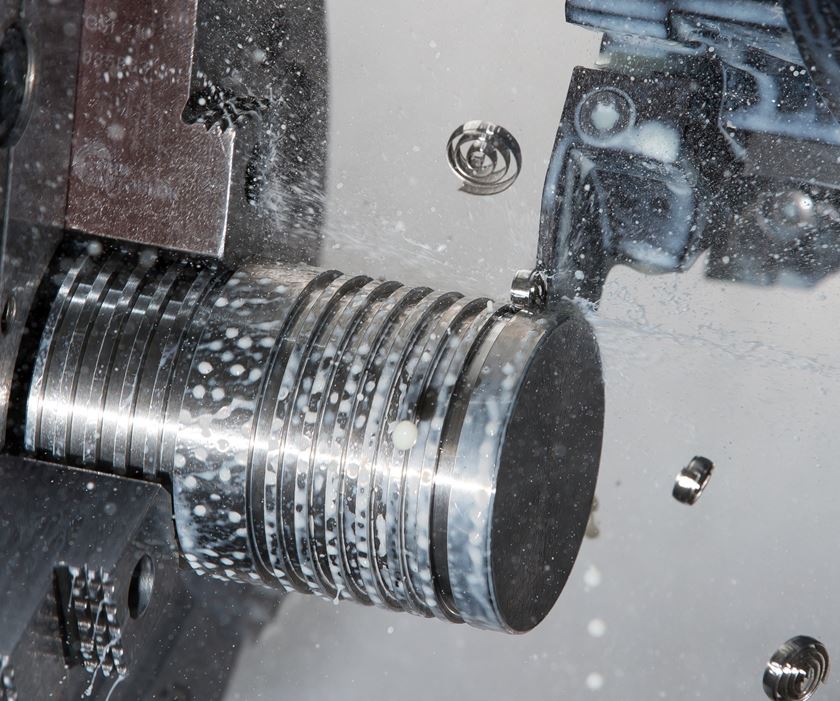

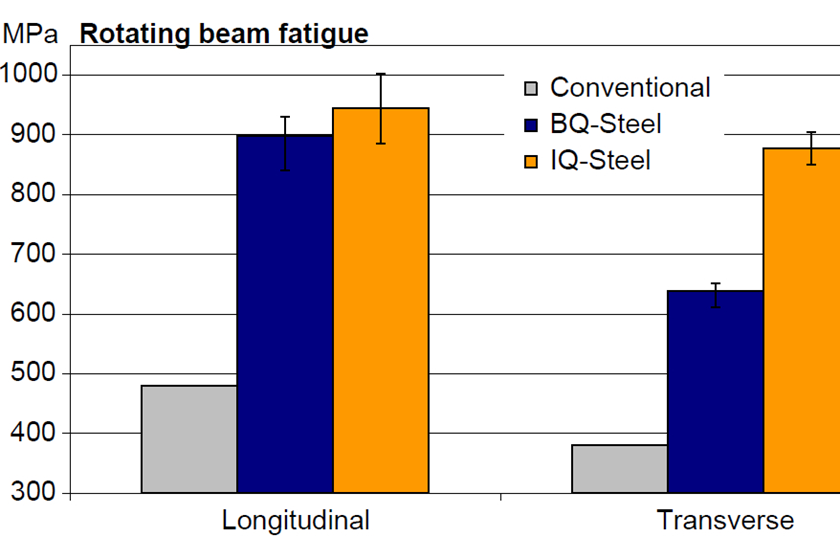

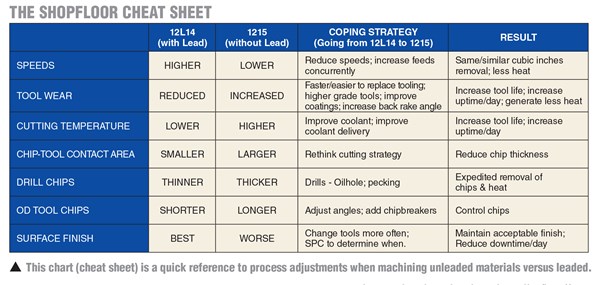

It is widely acknowledged that lead promotes machinability. To get the maximum production from automatic machines, additions of lead have been commonly used in metals, particularly steels and brasses. In brass, dispersed in the grain boundaries, lead acts as an internal lubricant: It reduces friction, and thus heat. By reducing the heat, lead allows the metals to which it has been added to be machined at much higher speeds than the comparable non-leaded grades. These higher speeds (rpm or surface feet per minute) result in shorter cycle times to produce each part. Short cycle times mean less expensive parts.

铅黄铜提供了以下历史优势:

- Excellent surface finish

- Forgiving of machine mis-adjustments

- No thermal issues

- Fast cycle times

- 没有芯片控制问题

When machining non-leaded materials, we have to somehow maintain surface finish, get to commercially feasible cycle times, and deal with less than ideal chip characteristics.

What are some strategies for machining the new unleaded brasses?

Increase the feed.由于我们失去了领先优势和更高速度运行的能力,因此增加饲料可以帮助我们达到等效的立方英寸的去除率。

Improve the machine rigidity.Heavier feeds mean that your machine needs to be adjusted and solid. It also means more horsepower required— again mandating a rock-solid setup.

改进工具。4%的领先优势非常宽容工具质量;新的非致密成绩恰恰相反 - 它们给您的工具带来了许多挑战。改进的材料,几何形状和涂料是加工无铅黄铜的关键,但问题最小。此外,他们将需要更少的替代品,从而帮助在轮班结束时获得更多的净生产。

Improve the chip management.Some unleaded grades replace the lead with zinc, resulting in a grade with a type III chip—stringy and bird’s-nest prone. With these grades, pay special attention to drills selected, and try inserts with chip control features to help you manage that chip.

处理增加热量。The lead helped to reduce friction and heat in the leaded grades. With the lead removed, you will have increased heat generated. Carbide is more forgiving of heat, as are tool coatings. Talk to your supplier of metalworking fluids. Chances are, they will have a fluid that will help manage those extra BTUs and maintain your tools’ edges.

改变您对加工黄铜的想法。Unleaded brass machines more like steel than brass as long as you think of it like leaded brass, you will fight it. Instead, think of it as just a yellow version of 1215 steel or stainless and your expectations will be much closer to reality.

Unleaded brasses are not necessarily harder to run than leaded brass.They are just different. By recognizing and accommodating for their lack of lead and the resultant different thermal conductivity, differences in chip forming, and the need to up the tool for heavier feeds rather than higher speeds, your shop can also be successful at making parts from these newer, more challenging grades.

The market for our precision machined parts continues to be evolve. Evolve your thinking and processing to adjust to the realities of unleaded materials to remain a viable and preferred supplier.

For more details on grades and recommendations, readAdjusting to Unleaded.

最初发布PMPAspeakingofprecision.comblog.