Workforce Is Still the Most Important Challenge

It is as true today as it was 10 years ago...workforce is top of mind for precision machining shops.

#pmpa

In November 2012, after returning from IMTS, I wrote an article for thesePMPApages titled “The Most Important Challenge”bit.ly/PMPA-PM0122。我从imt返回2012周的感觉load of new technologies and new ways to achieve the precision and accuracy demanded by our customers. I was struck by the contrast between the optimism these new technologies heralded, compared to the looming reality that our greatest challenge was finding and building the human talent needed in our shops. Everyone that I spoke with mentioned lack of skilled and trained people to work in our advanced manufacturing shops.

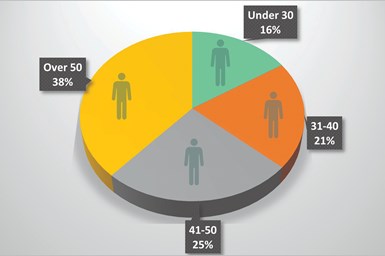

Precision Machining Workforce in 2021. Image Credit: PMPA

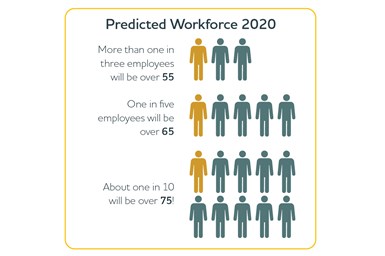

In that article, we shared a graphic projecting the demographics in our shops in 2020 (at right). The year 2020 came and went. But our projections for shop workforce hit very close to

the mark.

Featured Content

Recently, PMPA surveyed our Manufacturing Member shops to help us determine what is top of mind for our work in Washington D.C. Over 18% of shops eligible to participate responded, and we learned that workforce continues to be our No.1 concern.

The above graphic was the prediction in December 2012. Image Credit: PMPA

A look at the numbers shows that our 2012 analysis was very close to target. On our December 2021 survey (upper right image), the age brackets were different, but 41% over age 50 in the current survey closely agrees with “more than one in three (33%) employees will be over 55.”

When comparing the latest survey numbers with our projection in 2012, it appears that many of the oldest demographics have already left our workforce. This is easy to understand given our experience with COVID-19 in the past year, COVID-19 early retirees top 3 millionbloom.bg/34gUZ0O。

It is also understandable by looking at the increase in people’s savings — particularly in retirement accounts. Retirement accounts are at a new high.cnb.cx/3g6qj59

What do these numbers mean for our shops?Here are a few ideas to consider given this look at the makeup of our workforce today:

- We seem to have already lost a lot of our more experienced performers — capturing and sharing the expertise that remains should be a top priority.

- The talent seems to be spread evenly by age, so upskilling needs to be across your entire workforce, not just the new hires.

- Don’t look at training or mentoring as a one-way process. In my MBA teaching, I deliberately pair younger students with older, more experienced students. While the older students have experience to share, I have found that the younger students earn their respect as well as improve their skills by helping their older partners get comfortable with the new technology that is being used in the classroom. Create a process for capturing your processes and process knowledge. Many of our shops are ISO 9000, AS9100 or similar for management systems, so documentation shouldn’t be an issue. And yet, there are many things that have been worked out by our performers that actually empower and facilitate those formally documented processes. What are they? Who has them? How can they be learned across the entire organization?

- 安全。我们的员工表现是有价值的— critical to the success of our businesses. As I said in 2012, “It is skilled people that help our companies produce the high-precision, engineered components that make U.S. manufactured goods the gold standard which has been the only bright spot in the post-recession of the 2008-2009 recovery. Our industry has increased sales by double digit growth the last 2 years. But this trend cannot continue if we do not find a way to recruit and train more skilled people for our shops. The precision machining industry will not be able to grow our capabilities without adding skilled workforce. Many companies are already at their limit for what they can do without adding more talent — whether in engineering and quoting, project leadership and implementation, setup or operations. And who is making sure that our efforts for quality improvement remain a priority when we are in all-hands-on-deck mode?”

Those remarks are just as relevant and valid today as they were in 2012. And they highlight our duty to ensure the safety of these most valuable performers (MVPs). They are the people who are making the things that make a difference. They are the people who are satisfying the demands of our customers. Their safety is a critical part of our plan for success in 2022.

Workforce is still the most important challenge. The facts from our work in 2012 and our latest survey indicate that addressing this may just be the most important priority we have in 2022. Without sufficient workforce, we have no assurance that we can satisfy the continued peak demand that our customers trust us to deliver.

Read More Articles fromPMPA:

About the Author

Miles Free III

Miles Free III is thePMPADirector of Industry Affairs with over 40 years of experience in the areas of manufacturing, quality, and steelmaking. He helps answer “How?, “With what?” and “Really?” Miles’ blog is atpmpaspeakingofprecision.com; email –mfree@pmpa.org; website –pmpa.org

RELATED CONTENT

Craftsman's Cribsheet: How Sulfur and Manganese Improve Machinability

Because manganese and sulfur are intentionally added to the steel, manganese sulfides are present in the steel and at the edge of the tool where they optimize our machining process.

Recruiting for Manufacturing Part 3

Producing recruiting material can seem daunting, but you may be surprised at how many resources you already have in your shop.

Subscribe to PMPA Podcasts

"Speaking of Precision" is a podcast from Industry expert Miles Free III, in which he talks about precision machining. All episodes may be found on major platforms.