Triple Tap Life

A maker of vehicle components finds that a treatment process for taps produces dramatically longer tool life.

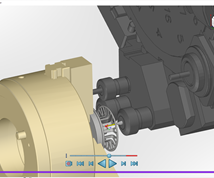

Team Industries生产设施在奥杜邦,明尼苏达州,最近推翻了Taps的刀具寿命,它用于机器铸铁液压机壳体。团队是底盘和电力汽车组件的制造商,用于越野和公用事业车辆。在11个螺纹洞和350,000个单位的年度,这一部件数为每年近400万台洞穴。龙头寿命的改善是 - 因此 - 非常显着。

这种改进也直接决定了公司支付多少才能实现它。团队行业厂将水龙头用于在第三方进程中进行治疗。这种过程占据了客户的40%,从而节省了挖掘支出,无论那些储蓄证明是什么。

Better Than New is the Chattanooga, Tennessee company that provides this treatment. The treatment process is called “RF85,” after an Oak Ridge National Laboratory test that documented an 85-percent reduction in friction. Although the treatment had been applied to surgical hand tools and to race-car components, it had seen little application in machining prior to Team Industries. Mike Selck, engineering manager for Team, learned about the process because of an accidental connection to Better Than New’s founder, and he decided to submit some 5/16–24 taps for treatment.

“当我收到工具后,我不得不打电话来确保这项工作已经完成了,”他说。治疗没有什么可以改变工具的外观。

But it does change the composition of the tool’s surface. In this way, it also changes the tool’s performance.

曾持续900份的团队行业的水龙头开始持续2,700份。因此,RF85龙头处理现已制定了电机外壳部分的标准部分,最终将是团队也是机器的其他部件号的标准。塞尔克先生说,税收支出的储蓄甚至不是储蓄的唯一主要来源。在他的工厂的过程中,治疗近距离支付恰好在更大的内切割时间,这是由于不必经常改变水龙头。

Not For Carbide

The details of the RF85 treatment are confidential, but Better Than New describes it as a bath that encourages the addition of calcium, among other elements, to the alloy of the tool. The treatment is not a coating. Indeed, the actual coating on the tool, such as the TiAlN on the taps sent by Team, is unaffected.

The company says the treatment does not work well on carbide. It works much better for steel. Further, because the treatment is a friction-reduction enhancement, it delivers the greatest value in applications that are high in friction. For these reasons together, the ideal machining application seems to be tapping—which is a high-friction process that uses HSS tools extensively. Tapping has been the focus of essentially all of Better Than New’s attention to machining so far.

For many shops, that alone is plenty. Tapping can be trying. At Team Industries, tapping has been the operation that most slows down machining, and taps are the tools that typically have to be replaced most often. Giving a try to a previously unknown surface treatment process was not difficult for Mr. Selck, because he had seen the plant try seemingly every other established solution in search of more affordable thread machining. The taps the plant currently buys—the ones it sends to Better Than New—represent the best value the shop has found after evaluating the relative price and performance of many different taps. Now, the plant is able to buy fewer of these taps, paying 40 cents on the dollar instead.

需要速度

Mr. Selck says he has noticed that speed is significant. The treated taps are used on three VMCs and one HMC, and tool life has improved three-fold on all four machines. However, there is also a spillover tapping machine in the facility—a manual multi-spindle drill press with much lower spindle speed. When the treated tools are used on this machine, tap life does not show as much improvement. Plant personnel assume the spindle speed difference explains why.

Accordingly, since speed has this influence on performance, Mr. Selck hopes to turn up the speed on the four machining centers’ tapping operations. That speed increase will come next, he says—the shop will measure how much tool life it can obtain at more aggressive tapping conditions.

In addition, the plant plans to apply the treated taps to other machined parts. One of these, a new part number coming from the same customer that receives the motor housings, is particularly promising—because this part is likely to feature just as many tapped holes as the motor housings have.

相关内容

清洁曲轴上的污垢

A high-pressure waterjet blasts away burrs and machining residues that resist more traditional cleaning methods.

For Plateau Honing, Consider Ball Style

滚珠式磨练是一种专业的磨料工具,可通过其独特的外观来瞬间识别。对于汽车,航空航天,制造和加工行业的工程师,这种应用工程磨练,其特征在于永久安装在柔性长丝的小型磨粒,是一种灵活的低成本工具,用于复杂的表面,去毛刺和边缘混合。

用自动化刮伤表面缺陷

Machining parts complete on CNC multi-spindles, with automatic load and unload, is proving the key to nick- and scratch-free parts for this tier-two auto parts maker.

.jpg;width=70;height=70;mode=crop)