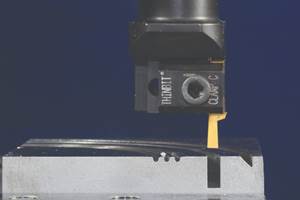

The complex geometry of bone screw threads is such that, while possible, conventional operations such as single-point threading can be tricky and time consuming. Multiple tool passes are required and, because the thread profiles are commonly deep, chatter can be an issue. That’s why shops sometimes opt for thread whirling, which is more akin to a milling operation using multiple cutting edges in a cutter body rotating around the part which create threads in one pass, offering higher metal removal rates and better finishes.

However, some modern bone screw designs have two thread leads as this enables faster, more controlled screw insertion. Traditionally, these screws might be machined with two single-point threading operations or one thread whirling operation followed by a subsequent single-point operation.

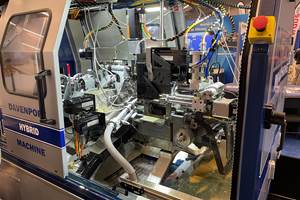

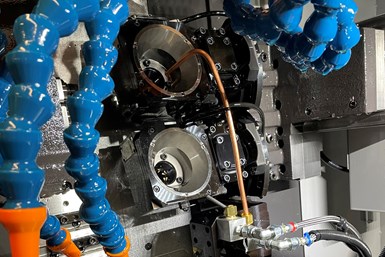

Tsugami/Rem Salesoffers an alternate option on its S206-II Swiss-type CNC lathes that offers the room to be fitted with two thread whirling attachments. That way, both thread leads can be created in one setup, eliminating a second single-point threading operation to speed overall manufacturing time.

The company performed a machining test of a dual-lead bone screw made from 303 stainless steel on a S206-II with dual thread whirling attachments. Cycle time for each screw was 4.79 minutes, which would produce 85 screws per 8-hour shift.

RELATED CONTENT

High Demand Creates Growth in Aerospace Industry

The combined results of a strong global growth of both passenger and freight air transport demand followed by strong demand for new aircraft and increasing competition between aircraft manufacturers should point to a robust aerospace market for years to come.

Considerations for Machining Exotics

In manufacturing, the term “exotic” is used to describe materials that display excellent wear characteristics, durability and service life in high heat, extreme cold or corrosive environments.

Vegetable Oil Improves Machining Of Medical Devices

Production management at this shop speculated that many of the materials used and operations performed might benefit from the higher level of lubricity characteristic of vegetable oils. Any consequent additional capacity and tool life would be a plus.