Take the Time to Walk Your Machine Shop

Scheduled strolls through your shop demonstrate that you’re not only onboard with your company’s open-door policy but you’re proactive about it. They can also help you better manage the time required to effectively support such communication initiatives.

#columns

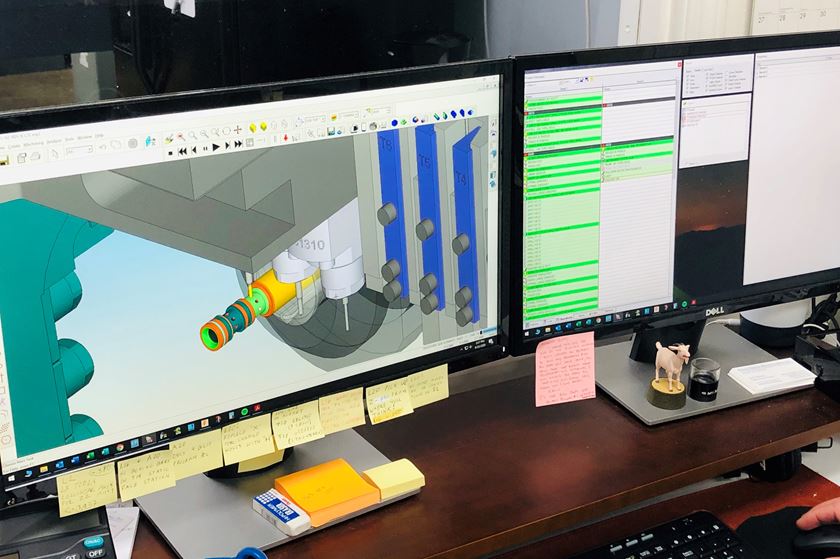

Some years ago, I got the chance to visitGreat Lakes Custom Tool, a manufacturer of custom woodworking and metalworking tools located in Peshtigo, Wisconsin. Russ Martin and his son Ray are company president and vice president, respectively. Russ also refers to himself as the company’s “Head Coach.” They told me they walk through their large facility each day because it enables them to chat with employees about anything and everything going on in the shop. It sometimes lets them catch a glimpse of employees’ problems or needs in the moment. These relaxed, simple strolls also show they are reachable and approachable. Although this daily drill sometimes lasts an hour, the Martins say the time is well spent.

Might such routine walks help you better manage the time needed to support open communication in your shop?

Featured Content

Although largely beneficial, conventional open-door policies tend to reduce a manager’s daily output. It’s not necessarily the total time devoted to helpful, private discussions with employees that’s the issue. Sporadic, unscheduled meetings break up long stretches of focus and concentration needed for some projects.

经常走路设施和说话employees offers another way for managers to learn about inefficiencies on the shop floor.

Passing through your open door to take scheduled walks, instead of waiting for others to find you, gives you some control over how your time is spent supporting effective shop communication. It enables you to have a number of brief one-on-one chats in one block of time, likely reducing the number of random visits you’ll receive. It demonstrates your understanding that workplace communication is a two-way street. It gives you an opportunity to solicit suggestions for ways to improve shop efficiency or trim manufacturing waste. Also, it offers a chance to comment appreciatively on the contributions that individuals make to the company.

You might not be able to carve an hour out of each day for such walks and that’s fine. Making these walks routine is arguably more important than how frequently you get to the floor. Expected visits won’t seem like little sneak attacks or give the impression that you’re only out there to check up on an employee’s productivity. Plus, consistent visits on the same day or at the same time give employees a chance to prepare questions rather than calling them to mind as they’re in the middle of their duties.

Frequent shopfloor walks can help better manage open-door communication.

Such open communication is certainly important these days given increasing global competitiveness. Employees have questions about the company and its position in the market, and it’s important to provide answers to the extent that you can. Not only will this boost morale but it will instill confidence that you are doing all that you can to keep the company on the right track.

So, consider taking such “steps” if you’re looking to get a better handle on open-door communication, and be sure to continue the exercise no matter if business conditions are ebbing or flowing.

RELATED CONTENT

Create a Virtual Tour of Your Shop

Open houses and tours are techniques leading CNC machine shops use to market their operations to prospective new customers and new hires. It’s also possible to do this digitally like Roush Yates Manufacturing Solutions has, which is helpful in these strange days of social distancing.

Preparing the Next Generation of Machining Talent: Q&A with FANUC America’s Joe Baldiga

What are FANUC and the machining industry doing to address the shortage of skilled manufacturing talent? We sat down with Joe Baldiga, who leads FANUC America’s efforts in Certified CNC Education and Workforce Solutions, to find out.

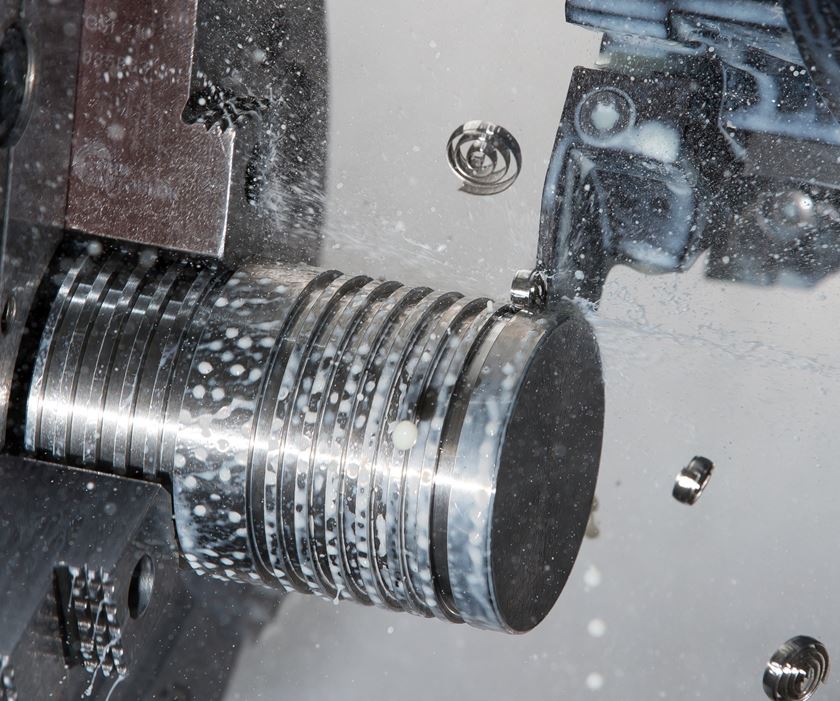

What Machine Shops Should Know About Material Bar Straightness

Many operations require a high degree of bar straightness, especially when the material is to be presented to a machine by a bar feeder. For that sector of the market, the following is a brief review of the steps your bar supplier can take to ensure positive results.