Start-Up Shop Makes Splash Machining Aluminum Guitars

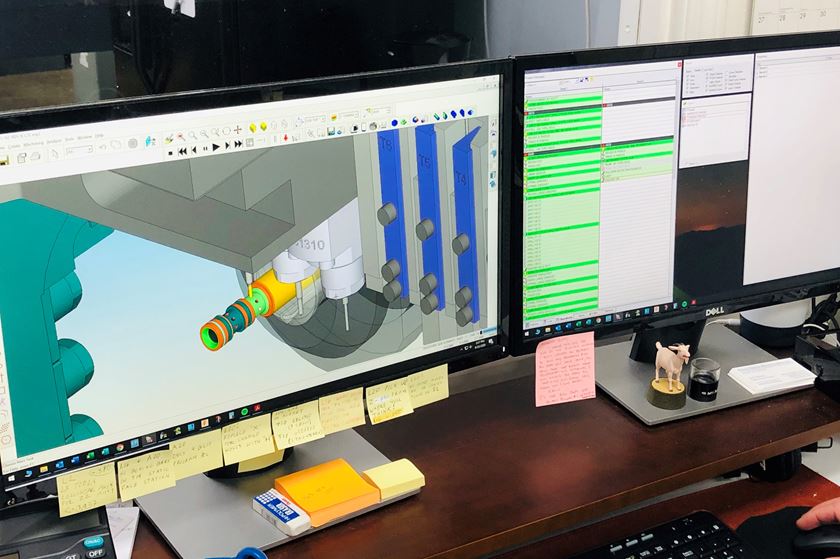

This shop needed a CNC machine to produce aluminum guitars. Equipped with probing capability and the visual quick code (VQC) programming system, the Hass VF-3 VMC has the flexibility to product not only guitars, but also a range of other components, including aerospace tooling, nautical components and automotive parts.

James Wilton gets to combine his talent for machining with his love of guitars at Coast Precision CNC. Mr. Wilton, who has 15 years of machining experience, opened his two-man shop in Richmond, British Columbia, in November, 2006. Although he caters to a wide variety of jobs, including aerospace tooling, nautical components and aftermarket automotive parts, arguably his most “flashy” work is machining aluminum guitar bodies and other components for the upstart Liquid Metal Guitars company (www.liquidmetalguitars.com).

Instead of being carved from traditional hardwood, these contoured guitar bodies are machined from billet 6061-T6 on an VF-3 vertical machining center (VMC) from Haas Automation (Oxnard, California). The VMC is the shop’s first CNC machine tool. Mr. Wilton, a third-generation machinist, wanted a machine that was not only capable and affordable, but also offered the flexibility to go after a range of machining work. Machine service and support was just as important, especially considering that it is the shop’s only CNC machine.

Featured Content

The VMC has X-, Y- and Z-axis travels of 40 by 20 by 25 inches, and each axis has a rapid traverse rate of 1,000 ipm. The 40-taper machine was specified so that it would be both versatile and relatively easy to operate, even for employees with limited experience. Options include a side-mount toolchanger with 24 tool positions, Renishaw probing and a two-speed gear box. The two-speed gear box provides the machine with the torque required for heavy cutting (250 foot-pounds at 450 rpm) in addition to 10,000-rpm spindle speed when needed. Thus far, the shop has machined materials ranging from plastics to 316 stainless steel. The VMC also has fourth-axis wiring and drive in case the shop decides to add a brushless-type rotary table and pursue four-axis machining work.

Probing capability and the machine’s visual quick code (VQC) programming system make it easy for operators to pick up workpiece zeros and measure for cutting tool offsets, Mr. Wilton says. After an operator installs tools in the toolchanger and identifies the tools to be measured for a job, the machine automatically performs all the tool measurements. This frees the operator to set up new jobs or perform other duties. According to Mr. Wilton, the Haas service representative was helpful in assisting the shop in writing macros for measuring for offsets.

Mr. Wilton began working with Liquid Metal Guitars approximately two months after his shop opened. The shop that the guitar company had first approached to machine the guitar bodies wasn’t helpful in terms of making small changes to the original model. That forced the company to continually pay the engineering firm that created the original CAD model to make the small changes. When the guitar company met Mr. Wilton and took note of his appreciation for guitars, machining experience and willingness to make small design changes, it decided to give the work to Coast Precision CNC.

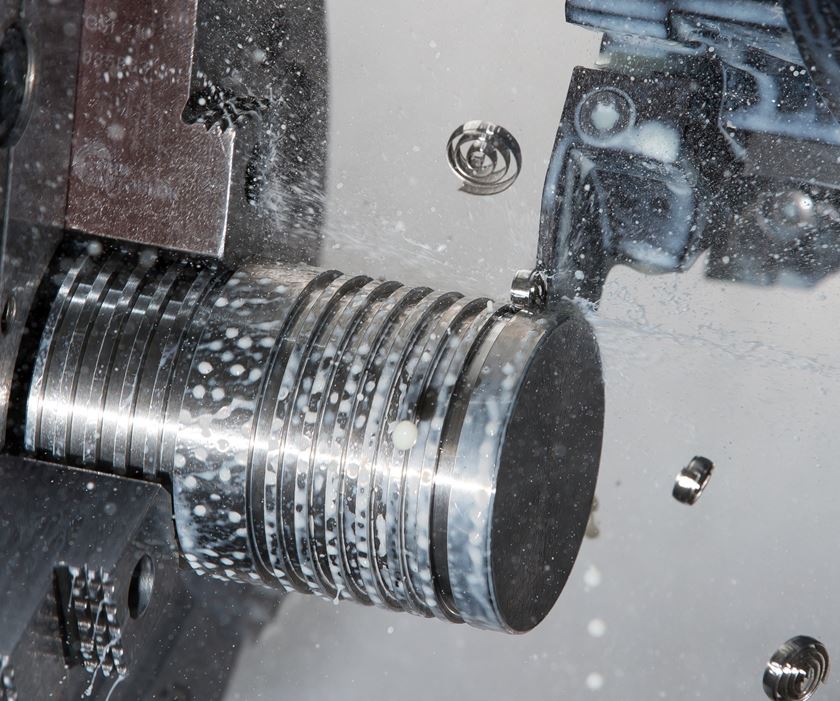

The guitar body was designed in SolidWorks, and tool paths were created using OneCNC, which accepts native SolidWorks files. The first steps in machining the contoured guitar body is skimming the top face of the billet aluminum and drilling clamping holes. Next, the workpiece is flipped so that the backside cavity with stand-offs can be machined (see top image on left). This brings the wall thickness to 0.125 inch.

The body is flipped again to lightly machine the topside radius in addition to the holes for the pickups and electronic controls. Then, the angled neck pocket is created using a dedicated jig. Finally, the body is fixtured to an angle plate to cut the hole for the 0.25-inch cord jack.

The backside cover is machined from 0.125-inch aluminum sheet. Mr. Wilton currently uses a dedicated fixture for the covers, but plans to use a vacuum workholding table as soon as guitar sales take off and the volume of machining work increases. The truss rod cover (a small plate at the top of the guitar neck that is typically made of plastic) is also machined from aluminum sheet. At first, these were fixtured with double-sided tape and machined using very small depths of cut. Now, Mr. Wilton uses a custom fixture that allows him to machine six pieces in one setup faster than he could machine one piece with the original method. He notes that the scrap rate is much lower, too.

Mr. Wilton says he still has a few ideas up his sleeve to speed part change-over and cycle time. He’s also experimenting with different guitar body finishes. It is much easier for the guitar company to communicate to Mr. Wilton the type of look it desires because both parties are knowledgeable about guitars and guitar design. He hopes the exposure that the shop will gain as Liquid Metal Guitars establishes itself in music circles will be parlayed into additional guitar work from other companies. Mr. Wilton also plans to design and machine billet guitar components that have traditionally been castings, such as bridges. He may also soon add a two-axis CNC lathe to complement the shop’s milling capabilities.

Mr. Wilton grooves on this work because he likes machining and loves guitars. To him, combining the two is magic—it brings out the best of the machinist that’s inside.

RELATED CONTENT

How Metallurgical Structure Affects the Machinability of Aluminum

Advancements in grain structure consistency and mechanical properties help to make this extremely machinable metal suitable for an ever growing range of applications.

High Demand Creates Growth in Aerospace Industry

The combined results of a strong global growth of both passenger and freight air transport demand followed by strong demand for new aircraft and increasing competition between aircraft manufacturers should point to a robust aerospace market for years to come.

Automated Cleaning System Improves Productivity

This rotary basket washer drastically reduced the number of operators tending to the cleaning process as well as removed the bottleneck from that station.

.jpg;width=70;height=70;mode=crop)