这座占地7,000平方英尺的建筑提供的装配空间是Hirsh Precision的Boulder,Colorado,Colorado和Thempquarters总部的四倍。购物车上的移动装配站可以在必要时轻松地构造到单元格中。

Hirsh精密产品是一家由史蒂夫·赫什(Steve Hirsh)创立的一家加工和制造公司,42年前,他将菲亚特X19换成了膝盖磨坊。我在最近的一次访问中注意到,该膝盖磨坊仍然居住在科罗拉多州巨石的工具室中。但是,从那以后,发生了很多变化,并且该公司在整体规模和技术和流程的复杂性方面已经增长了很多。

医疗行业正在推动这种增长的很大一部分。该公司大约在30年前开始为医疗客户提供服务,并于2020年完成了ISO 9001:2015认证的高跟鞋13485认证,该认证在此之前就完成了几年。该行业的工作代表公司销售的三分之二,其余的包括航空航天,科学和一般工业应用的工作。

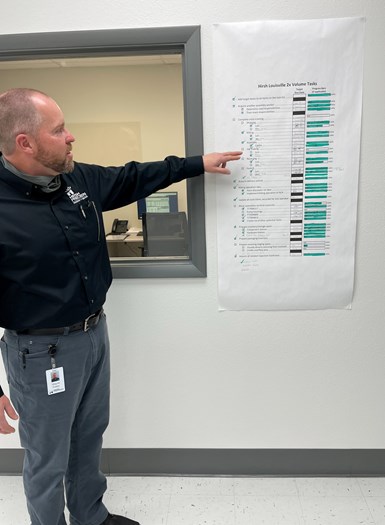

The company’s proprietary shop management system shown here being used at Hirsh Boulder is also used at Hirsh Louisville. This enables data to be shared and accessed easily at both locations on one platform. The software serves as an intuitive front-end interface with the company’s enterprise resource planning (ERP) system fromInfor ERP。

当我说制造商已经变得很大时,知道它最近发现了其30,000平方英尺的总部,其所有CNC加工设备都在接缝处爆裂,完成了整理过程(例如柠檬酸钝化),质量控制和产品组件。而且,没有可用的空间来扩展建筑物。

为了支持该公司的增长并扩大了对医疗和航空航天客户的复杂集会服务,Hirsh Precision产品决定建立一个专门用于组装和库存管理的单独设施。2020年9月,它将大部分操作转移到了附近科罗拉多州路易斯维尔附近的7,000平方英尺的建筑物。这个被称为Hirsh Louisville的新设施提供了装配地板空间的四倍以及改进的照明和更具控制的环境,以促进四名组装员工在那里执行的精确工作类型。

Hirsh Louisville总经理Wayne Fraley说,该地点目前生产27个不同的集会。但是,他指出的目标是在接下来的几年中及时增加这一数字,以便为即将到来的公司进行另一个重大变化。

将组件移至专用建筑物,在Hirsh Boulder释放了一些地板空间,以提供其他加工设备。例如,该公司最近添加了第三个Okumafive-axis VMC to its high-productionFastems灵活的制造系统(FMS)。

采用“全方位服务”方法

弗雷利(Fraley)说,将公司称为“机械车间”并不能最好地反映全部内容。“我们更多的'全方位服务'方法使我们能够处理客户的机械和电力组装;代表客户的供应商和供应商来源零件;使用我们的专有商店地板管理软件跟踪产品的生产,组装和运输;并从头到尾管理制造和组装产品的供应链。”弗雷利说。

总裁兼首席执行官彼得·道尔(Peter Doyle)补充说,这不仅仅是提供集会作为服务。“我们的工程团队能够与客户交谈,而不仅仅是一个特定的部分,还可以与该零件交流,其目的是什么,组件的功能等等。这使我们的团队处于更好的位置,可以与客户的工程师进行咨询,以提供可制造性的反馈,同时为我们的团队提供对生产最终产品的所有流程的所有权感,” Doyle说。

在Hirsh Boulder仍在执行“串起”,以完成需要40,000-PSI流的零件以及这些零件的某些组件的孔口孔。

Hirsh Louisville is just a 20-minute drive from Hirsh Boulder within the Colorado Technology Center (CTC) industrial park. In fact, the building was perfectly suited for the clean assembly work to be performed there. The facility was previously used by a food processing company. It is well-lit and had multiple existing electrical and compressed air drops throughout. No real modifications were required outside of bringing in assembly equipment such as manual presses, hand tools and gages from Hirsh Boulder.

路易斯维尔赫希尔(Hirsh Louisville)提供1,600平方英尺的装配空间。其余的专门用于库存存储和包装以及销售和营销的办公室。大多数装配工作站都使用移动凳,因为它们可以轻松地操纵为某些项目创建组装单元。选择的组件可能具有多达几十个不同的组件。其中一些是在Hirsh Boulder加工的,而另一些则是紧固件和弹簧等。

密切沟通与Hirsh博尔德和machining and inspection expertise facilitates the creation of fixtures for assembly presses as well as instruments such as this go/no-go gage. The shop can also laser mark devices such as this to tie it to a given product.

Approximately 50% of metal machined parts require anodizing, which is performed at a finishing company in Colorado Springs that Hirsh Precision Products had been partnering with and recently acquired. Final inspection of those parts is completed at Hirsh Boulder and then sent to Hirsh Louisville. There, those parts and sourced components are received, inspected (if they are sourced components), entered into the company’s proprietary shop floor management software (a common platform used at both company facilities) tracking them to a specific job and then put into inventory. Pick lists are then created and jobs are kitted on individual carts. Completed assemblies can then be packaged to prevent damage and shipped. These might be subassemblies or completed products for customers to sell.

同样,两个位置之间的紧密通信使得为组装压机以及诸如GO/No-Go级仪器等仪器创建固定装置变得容易。Hirsh Boulder还可以激光标记仪表和其他设备,以识别给定产品。

将所有这些融合在一起

While the Hirsh Louisville building the company is leasing for its assembly and inventory management efforts was a necessary addition, it is a temporary solution. The company plans to move into a new 65,000-square-foot facility combining both the Boulder and Louisville operations under one roof.

Wayne Fraley, general manager of the Louisville facility, explains a checklist of training and operational goals, and ideas for this new assembly and inventory management location as it is part of the company’s culture of continuous improvement.

This new building is slated to be completed and operational in 2023. In the meantime, the company is determining an optimal layout to maximize flow, including where the assembly area will be located and how the current Hirsh Louisville operation will be replicated.

弗雷利(Fraley)表示,该公司希望在搬迁时将大会的目前产量达到其目前的近30个产品的两倍。这使公司有时间在搬家之前对其组装业务部门进行微调和扩展。

Automated assembly processes are always considered, although Luis Gonzalez, assembly supervisor at Hirsh Louisville, says not all assembly processes lend themselves to automation. For example, he says some assemblies feature plastic components that require a bit of finesse and care when pressing in pins so as not to damage the part. Plus, the complexity of other assemblies would be a challenge to automate.

无论如何,一旦新建筑启动并运行,我都会标记我的日历。我总是喜欢以这种方式比较和对比创新的制造公司。

RELATED CONTENT

今天和明天的制造医疗设备

The pace of change in medical device design and manufacturing is rapid and is fueling demand for machine tool capability that not only reduces cost per piece today, but can open doors to producing new types of parts in the future.

为微加工进行工具

Choosing the right tools and matching them to the correct operations and process techniques for micromachining applications is critical to success in this burgeoning market.

软件桥接牙科植入物制造商的缝隙

这家牙科植入物制造商发现了技术和人员的正确组合,以帮助实施其不断变化的哲学,植根于控制其制造过程。