Connectivity and data collection have become overarching themes in machining and manufacturing. Machine tool OEMs and accessory suppliers continue to build automatic feedback/monitoring capabilities into their equipment to enable shops to have greater control over their shopfloor processes. For example,Hainbuch America Corp.is providing intelligent capabilities on its TopPlus IQ chucks and mandrels. These intelligent workholding devices are integrated with sensors that include part measuring and workholding parameter monitoring capabilities. They are designed to improve workflow by reducing measurement procedure times and decreasing scrap while relaying data to the machine controller for analyzing and process adjustments.

像公司的其他劳动产品一样,智商技术是根据客户投入来创建的,以确定如何最好地设计设备。Hainbuchauch Applications工程师Jim McCraw说:“我们必须确保我们保持产品的完整性,并适应未来的增长。”“ IQ Chuck/Mandrel系统正在基于客户反馈,包括我们放置传感器的位置以及试图捕获的数据类型。”

特色内容

He adds that with the help of customers, the company’s R&D department can test the chucks/mandrels as they develop them while leaving room for future product growth.

自动测量和监视

麦克劳说,机械车间不断地对Chuck或劳动设备内部发生的事情以及它如何影响工件的结果感到好奇。因此,IQ Chucks和Mandrels的自动测量和监测功能是该公司劳动产品阵容的自然进步。

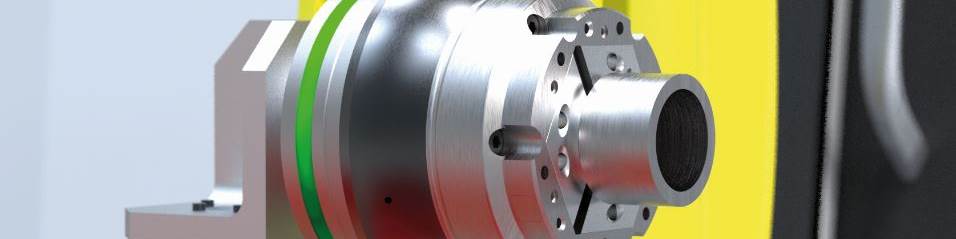

The IQ chuck can be used for measuring the finished workpiece diameter. This data is processed in the controller or in the master computer and is also shown on an LED ring on the chuck. Photo Credit: Hainbuch America Corp.

传统上,机器操作员需要密切关注过程特征,例如温度,夹紧压力,僵化和工件设备和工件的振动,并记录他们的发现以备将来使用。Hainbuch Engineers认识到潜在的人为错误并依靠运营商的经验可能是有问题的,因此将智商劳动力设备设计为自动,更准确地捕获此数据并将其传输到数据库。

“This way, an operator doesn’t have to try to digest what is happening inside the machine and then make decisions about how best to fix it,” McCraw says. With the IQ technology, the critical aspects of the workholding process are programmed into the device and then it outputs accurate information that is reported to the machine control.

The measuring and monitoring possibilities of the TopPlus IQ workholding devices include:

- Clamping and measuring in one step,不使用独立的测量机。该特征可以检测到上游加工中是否产生正确的直径。

- 通过传感器检测工件接触in the basic body and through the three-point part support contact on the workpiece end-stop. The sensors can potentially detect chips on the workpiece end-stop without complex air sensing control with a rotary unit and piping.

- 测量夹紧装置的温度。This capability can detect a gradual temperature change caused by the machining process.

- Measuring the RPMs of the clamping device.Knowing the speed can be ideal for condition monitoring for the preparation of RPM-based analysis diagrams, detecting inertia losses.

- Continuous clamping force monitoring directly on the workpiece.Deviation from a calibrated clamping force value is determined this way, but does not provide an absolute measurement. Monitoring can detect if the hydraulic unit/clamping cylinder’s clamping force is suitable for the workpiece. In addition, analysis of the clamping force measurement data enables reliable-process manufacturing and is an important component of maintenance as needed.

Although all this information is possible to collect, many machine shops choose only to gather certain information they feel is most helpful to their applications. This process is a touchless transmission of data and energy between the rotating clamping device and the stator fixed on the headstock.

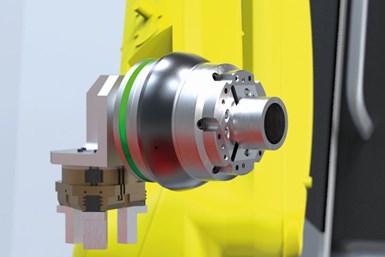

There are three ways the IQ workholding devices can be used for measuring/monitoring: 1) on the machine; 2) when handling the workpiece, and 3) at a measuring station. Photo Credit: Hainbuch America Corp.

Data Distribution

机械车间可以确定从智商技术收集的数据以及手动或自动处理该数据。例如,一个选项是让智商Chuck/Mandrel在图形用户界面或显示上显示某些信息,即直接从传感器发送给操作员的数据以供他/她响应。或者可以对智商劳动系统进行编程,以便数据可以反馈到机器控件中,并且作为响应,机床可以根据设定点进行调整,或者如果满足磨损点,则可以根据设定点进行调整。客户与机器构建器合作,因此他们可以通过机器的控制来建立所需的路径或响应。

“Some shops want the process as automated and remote as possible,” McCraw explains. “It depends on how critical the process is and how much interface they want the operators to have.”

此外,根据McCraw的说法,机械车间必须考虑它们选择在该系统中基础的连接循环类型。公司不仅可以发送数据并共享数据,还可以接收共享信息。

智商技术收集的数据可以保存在公司内,在公司家族中,也可以与所选网络共享。数据共享和信息隐私必须在系统中仔细考虑和监视。

选择的连接循环类型确定数据传输的功能。但是,通常,智商传感器将信息直接发送到机器控制器或图形用户界面。数据还可以转到工厂网络进入中央系统,该网络可以将数据与其他工厂工作中心发送的其他数据一起使用,以数字化处理工厂的整体流程和输出。然后,该中央控制系统可以与外部供应商和资源进行连接,以使用其数据来调整其内部操作。

“This is where the gateway can expand to the Internet of Things and either share this data with remote resources or take in pertinent shared data from other sources,” McCraw says.

The Operator’s Role

Although the IQ chuck/mandrel system is considered automatic, the system is taught what to do by the operator and is, therefore, not a completely hands-off

This IQ mandrel is for measuring the finished workpiece bore. Data processing occurs in the controller or in the master computer and can be output via a display at the measuring station. Photo Credit: Hainbuch America Corp.

device. Also, depending on the particular application, human input can be very beneficial. For example, an operator must recognize when certain technology is not operating correctly and then intervene when necessary.

In most of these automated systems, customers are striving for control of a process and have consistent reactions to symptoms that need addressing. “So, if they are manually responding to a symptom that has been fed back to them by a sensor, the end effect of the IQ technology is going to only be as reliable as that operator is with correcting the problem,” McCraw explains. But, with automatic compensation within the machine's controller, machines are always making decisions based on facts that have been programmed into them. As much as technology relies on us, we must rely on technology. We are dependent on each other’s accuracy, he adds.

一次自动化

Hainbuch’s TopPlus IQ workholding technology enables shops to integrate automated processes as described gradually. One or two sensors, chucks or measuring stations at a time can be integrated into a machine tool so automation does not have to happen all at once.

“I think the more people realize the benefits of implementing the automation on a small scale, the easier it is to justify it with larger investments,” McCraw explains.

These intelligent workholding devices’ benefits are clear, especially for high production applications. The automatic IQ chucks and mandrels increase machine productivity and process capacity, ensure a necessary maintenance schedule, monitor defined clamping forces and document the results to replicate repeat projects.

Hainbuch America Corp. |hainbuchamerica.com

RELATED CONTENT

Getting Ready for Lights-Out Manufacturing

灯出来的制造业有可能在增加产能的同时节省资金,但是商店需要正确的设备并在实施之前应对潜在的挑战。

5 Facts About Thread Rolling

Unlike subtractive processes, thread rolling does not remove material but instead moves and molds ductile metals quickly and precisely into the thread form using a cold-forming process. Learn more about thread rolling and tooling advances here.

Turning to an Adhesive for Lathe Workholding

Adhesive cured by ultraviolet light is an option for securing parts for machining that could otherwise distort when traditional, mechanical clamping techniques are used.