精确的加工行业面临着一个不懈的挑战,即不断地寻找提高生产率的新方法,同时确保持续生产高质量的组件。高效的工具和加工方法涉及提高饲料率,提高切割速度并增加切割深度 - 同时保持最重要的质量。

Cutting tool manufacturers are rising to this challenge. This month, our Technology Showcase is highlighting some of the product information that下午received from supplier companies. For April, we focused on cutting tools, including standard coated-carbide ISO-P steel insert grades for common steel turning operations; drilling units customized for particular operations; IG6 and SG3 coatings for cartridge tooling systems; and more as described below.

For the latest new products across the broad spectrum of precision machining, check out Production Machining’sNew Products online.

如果您想了解有关精确加工行业中最新新闻,产品技术和运营最佳实践的更多信息,请考虑订阅生产加工free monthly print magazine.

阅读:精密加工技术评论2022年3月:软件

阅读PM的March Technology Review.

Click on each link below to read the full product post:

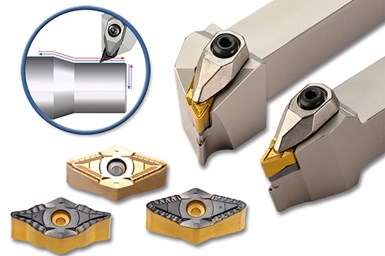

Ceratizit具有三个新的标准涂层ISO-P钢插入等级,用于普通钢转动操作,据说与上一代相比,工具寿命最高20%。该公司表示,这些插入物经过高度设计,可提高生产率,并具有先进的底物,几何形状和Ceratizit的Dragonskin多层涂层,以减少热量和更少的工具磨损。

Suhner’s Economaster drilling line offers inline vertical configuration and multiple spindle heads for medium-duty production drilling, with many other available spindle options and toolholders. The drills are suited for multiple materials, including light metal, wood, composite, plastic and foam.

Horn has developed hard and tough coatings with homogeneous structures designed to offer improved cartridge tooling system performance. The company says its IG6 and SG3 high-performance coatings can extend the service life of carbide tools by over 1,000%. These coatings are less than 0.005-mm (0.0002") thick.

Sandvik Coromant offers two microdrill families specifically designed for precision machining. The CoroDrill 462 with -XM geometry and the CoroDrill 862 with -GM geometry support industries with high demand for small part manufacturing, including medical, automotive, electronics and aerospace.

Ingersoll Cutting Tools says its SuperTurnZ inserts are an innovative system for multidirectional turning which uses the front and back cutting edge of a four-corner insert in a single tool. The inserts are said to be a productive alternative to conventional turning where 80-degree and 35-degree corner inserts are fed in the same direction. Instead, these inserts use all four directions available on a conventional two-axis lathe (+Z, -Z, +X, -X) to maximize material removal.

Photo Credit: Allied Machine & Engineering

Allied Machine and Engineering的465(464)系列Wohlhaupter精细钻头具有内部平衡,包括3ETECH数字调整以及模拟游标量表调整。一个3Etech数字读数可用于多个适应性的3etech无聊的头部工具,包括Variobore,538(537)大直径盒,465(464)精细的无聊头和自定义工具解决方案。

相关内容

Some primary factors are often overlooked when considering how to justify the implementation of a bar feeder for turning operations.

Here's a look at one of the oldest and most efficient methods of screw machine production for parts that are long and slender, with close-diameter tolerances and finishes, or parts that require truly spherical radii.

对于许多商店,该决定归结为4英尺或12英尺的杂志风格的酒吧喂食器。以下是它们之间选择的一些准则。