News of Note: July 2019

New options for training young folks, NTMA offers blockchain services, a new partnership promoting additive manufacturing in aerospace work, and other industry news.

Vocademy’s Maker Skills Academy.

Vocademy’s Maker Skills Academy (MSA) is a hands-on skills program that covers vocational, career and soft skills training. The six-month program is open to anyone 16 and older with no prerequisites, transcripts or GPA requirements. The first 10-student MSA team starts July 2019, and enrollment is currently open.

The academy states that this program is ideal for students seeking an alternative to college, a learning program to explore maker skills, an effective pre-engineering program before entering university or a set of job skills that will “make their STEM or maker careers future-proof.”Read more.

Here is some more industry news of note:

- NTMA Partners with Blockchain Supply Chain Firm SyncFab– SyncFab uses blockchain “smart contracts” and data-driven methods to optimize the external supply chain available to OEM buyers.Read more.

- Mitsubishi Offers CNC Total Care Package for Maintenance Needs– The Total Care Package provides maintenance by combining three existing services: CloudCNC backup, machine tuning and preventive maintenance.Read more.

- Oerlikon AM and MT Aerospace Partner to Accelerate Use of Additive Manufacturing的伙伴关系旨在扩大使用additive manufacturing in aerospace applications.Read more.

RELATED CONTENT

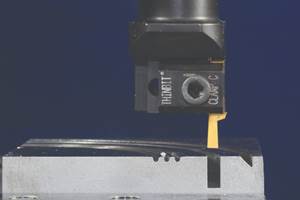

Broken Tool Detection In Machining And Turning Centers

Renishaw's TRS2 broken tool detection system uses a "one-box," single-head design to recognize tool reflections, bringing precise, in-cycle laser monitoring to machining centers and other machine tools.

Five Options for Higher Productivity

Today’s market is more competitive and time-driven than ever, and seemingly small workflow improvements can often result in huge gains in the medium and long term. Accuracy and throughput can be greatly increased simply by choosing the best tool for the job.

Gaging Is Baseless Without Standards

Applying gaging standards consistently is the key to quality parts and products.