在精确的加工世界中,“自动化”一词通常会唤起机器人的图像来照看机床。机器人自动化肯定对面对熟练工人短缺的商店以及希望执行长时间无人值守的加工的商店产生了重大影响(在某些情况下,有些灯光,一夜之间)。例如,第30页上的文章描述了一家商店的故事,整合了自己的机器人,该机器人最终与改变托盘的VMC配对,用于大量的工作钻孔不锈钢管。有趣的是,机器人自动化是在为其提供支持之前就进行的。此外,第26页上的文章解释了将机器人集成在CNC转弯中心内的优势。这种设计不仅提供了优势(例如减少地板空间),还可以使用机器人改进芯片疏散,以将冷却剂流在切口点引导,并使用机器人在转弯时帮助支撑长工件以最大程度地减少chat不休。

您在PMTS上自动化吗?

However, there are myriad other forms of automation that shops can leverage to their advantage even beyond bar feeders, the most common means to automate a CNC turning center. Many examples were evident at the recent精密加工技术显示(PMTS)held last August in Cleveland, Ohio. Here, we describe five: automated data collection from all CNC machines in one exhibitor’s booth, vacuum parts collection, 3D part measurement, tool presetting and parts cleaning process monitoring.

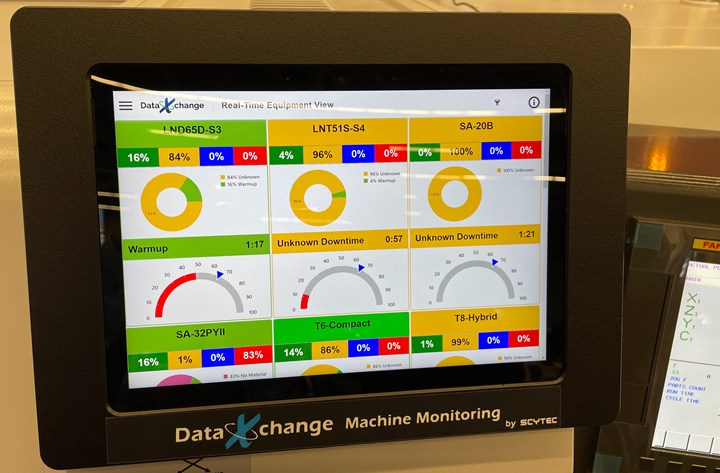

所有六台CNC机器绝对机床包括LICO,Nexturn和QuickTech品牌在内的PMTS展位通过DataxChange机器监视技术连接Scytec。整个展位中的监视器和显示器显示实时机器状态以及软件中可能的可配置仪表板和数据接口。这个想法是说明如何以类似的方式连接整个机械车间。Scytec说,那些新手的机器监控系统的人通常会询问如何连接机器并确保安全。那些在机器监控系统方面有一定经验的人更有可能询问如何处理数据。该公司建议商店首先连接和监视几台机器,并按时跟踪简单的指标。在那之后,商店可以“随着数据生长”。Scytec表示,由于它提供了每月,一年和两年的订阅,因此在没有大量前期投资的情况下,很容易开始小。

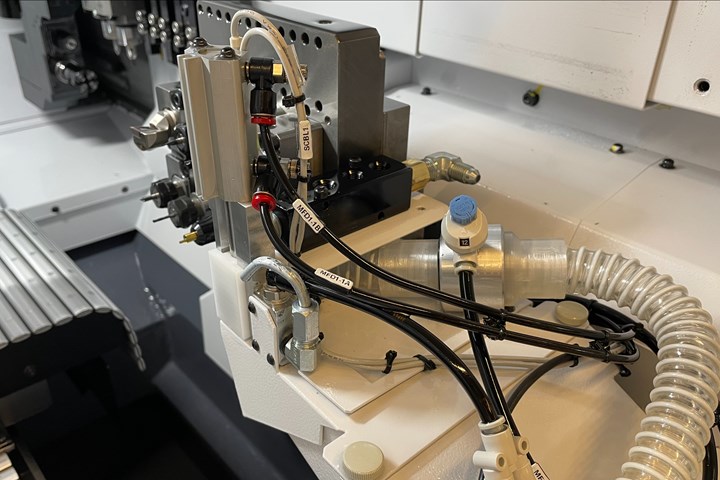

加工后自动拆卸和处理零件可能会具有挑战性,尤其是对于可能在芯片输送机或传统零件斜槽中丢失的非常小的零件,并且/或不能相互影响,从而导致其表面受到损坏。对于瑞士型车床,例如其L20 XII B轴机器,带有自动刀具,Marubeni公民提供一个可选的真空弹出系统,以一旦加工完成,以拉动和收集小零件。该系统由一个3D打印的设备组成,该设备可创建真空并拉动由主轴弹出的零件,并通过管子弹出,然后进入3D打印的收集设备。收集单元的漏斗形状会减慢零件,以免损坏它们,因为它们轻轻地掉到了单元的底部。系统使用计时器或传感器来确定零件何时输入收集单元,然后关闭真空设备。

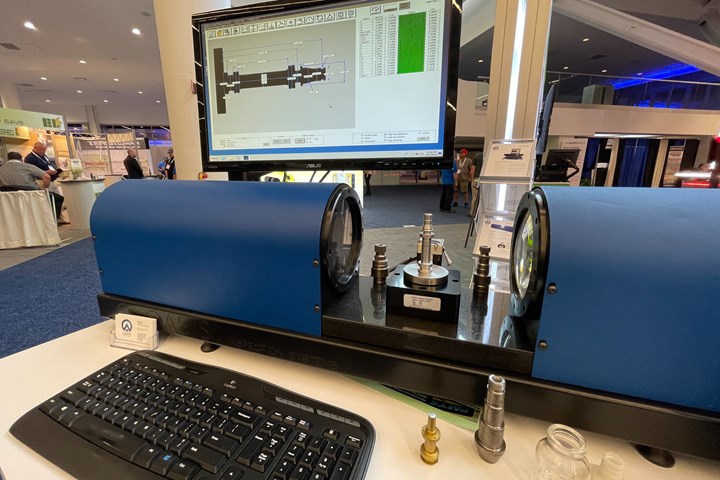

零件测量可能成为瓶颈,尤其是对于大批量生产商店。诸如非接触光学系统等设备绿洲检查系统自动在不到一秒钟内同时和实时地测量小零件上的多个轮廓尺寸。实际上,添加电动旋转阶段将这个2D检查过程变成了3D过程。检查员可以确保其零件在规格范围内一直限制,而无需手动转动零件。此外,旋转零件还可以增加检查其他功能,例如圆度和同心性。通过随附的软件更新,所有这些附加数据都用内置的OASIS检查报告记录,或者可以自动导入到任何统计过程控制(SPC)程序中。在连续模式下,该零件以用户定义的速度在舞台上连续旋转,以使检查员能够在零件转弯时查看测量和状态显示面板。在固定持续模式下,检查员定义了阶段将进行多少旋转,以及在旋转时测量零件的次数。

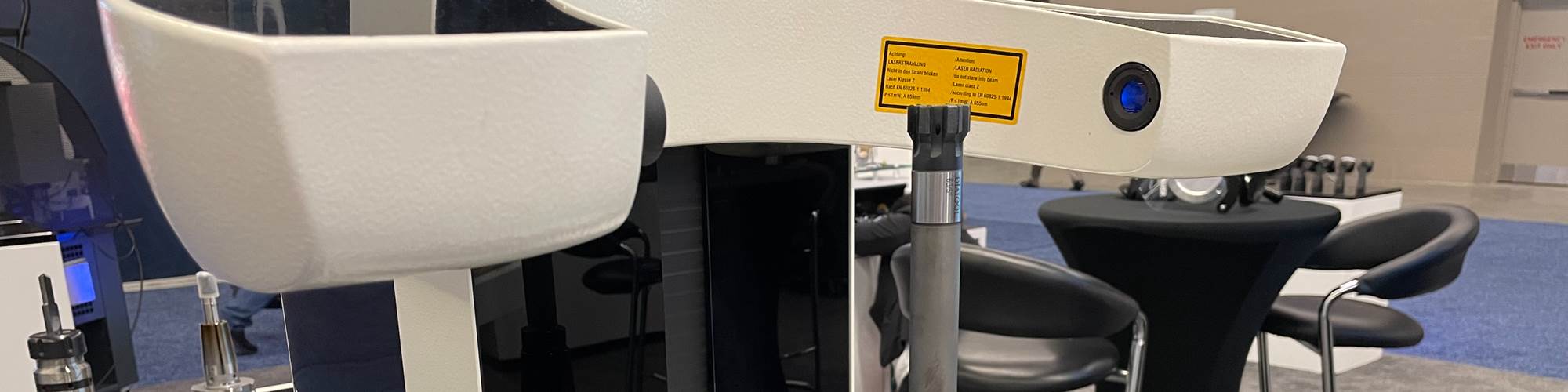

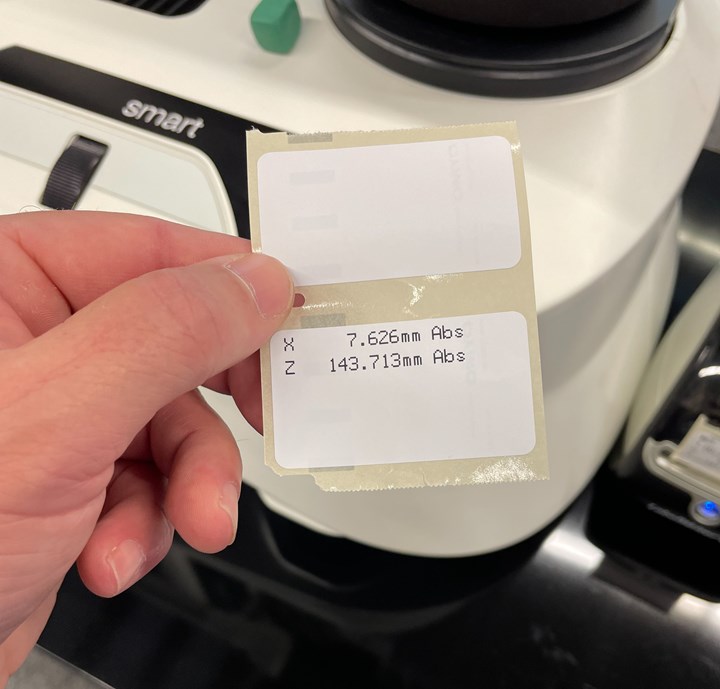

手动测量工具偏移是一个耗时的过程。Haimersays it commonly takes 300 seconds per tool to measure a tool in a machine. Plus, when using a machine tool as the “presetter,” an expensive piece of equipment is not doing what it is supposed to be doing — making chips. The company says this time can be reduced by 70% using an offline tool presetter to automatically measure attributes such as tool height, diameter and runout. Even entry-level presetters can support as many as 10 machine tools. In fact, Haimer has 140 machine tools in its 200,000-square-foot German manufacturing facility in Igenhausen, near Augsburg. In the main tool crib is a Vio Linear full CNC tool presetter. However, when a tool breaks on a machine far from the tool crib, the operator can choose to use one of 10 Uno Smart tool presetters installed throughout the facility to change one tool rather than walking to the tool crib. For live-tool lathes, presetting complements the company’s new line of shrink-fit collets that enable faster changeovers for those types of machines than conventional collets, too.

部分清洁需求继续变得更加严格,并且有各种各样的清洁方法供商店考虑。Ecocleansays its EcoCwave aqueous parts cleaner with a spray-flood cleaning system and vacuum-tight work chamber offers advantages in that it can be configured to suit a variety of applications. In addition, the company offers automated process monitoring with Ecoclean Connect cloud-based software designed to optimize the acquisition of parts cleaning data while displaying all system and process data on a computer or tablet. Defined data generated by the cleaning system’s control unit is transmitted to the cloud in encrypted form via a secure connection. The company says data is stored, evaluated, analyzed and intelligently linked using the latest Internet of Things (IoT) technologies and infrastructures. Process visualization includes preselections and step sequence display; operating data history; overview of key performance indicators such as utilization and effectiveness; message archive; and statistics. Documentation includes an overview of all cleaning processes performed; individual cleaning process reports (including process parameters); management of cleaning programs with version history and reporting; a library for all key documents related to the system; and a timeline for important events.