Just the Ticket for Ultrasonic Cleaning

USHERS机器和工具添加了另一种超声波配件垫圈。

Nothing says a happy customer more than those who come back to buy a second parts cleaning machine …especially if the next one is even larger than the original.

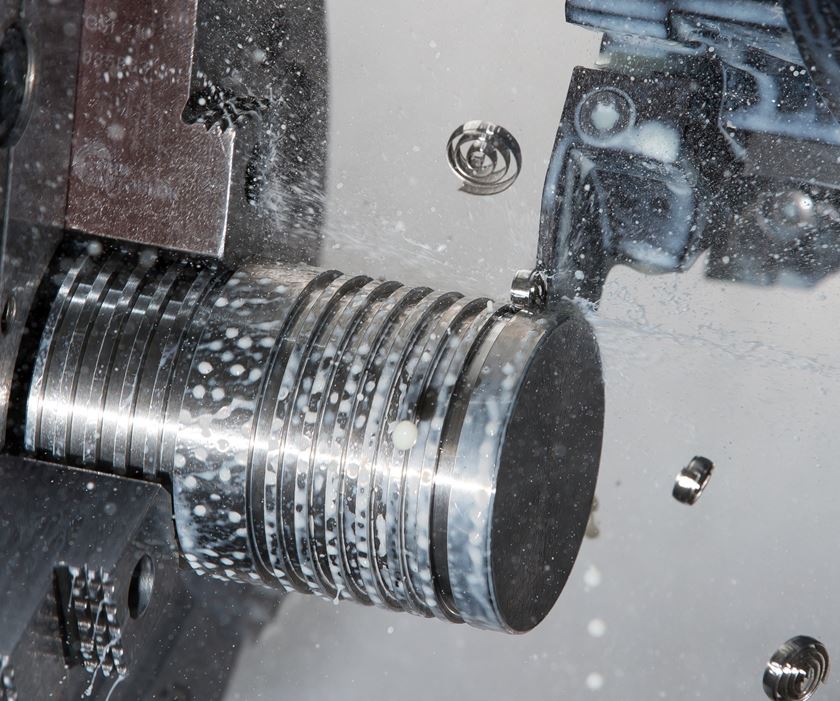

But that was the case with Ushers Machine and Tool Co., located in Round Lake, N.Y., which has been using Ultrasonic Power Corporation’s 39-gallon parts washer console for several years to clean stainless steel gas tips that were covered in machine coolant before they were sent to be chrome plated.

Before getting the ultrasonic cleaning system, and after doing the work by hand for several years, Ushers’ Quality Control Manager Nick Jones says the equipment has been a blessing for his lean operation.

“这对我们来说真的很大,”琼斯说。“只要我们看到它可以为我们做些什么,即在挽救男事时间以及给我们更好的表现时,我们就知道这是票。”

欧海机械和工具公司在圆湖,N.Y.,需要清洁机器冷却剂覆盖的不锈钢气体尖端,然后送铬镀层。

琼斯表示,使用化学品和纸巾,使用化学品和纸巾,通过使用化学品和纸巾来清洁Quers,精密加工,焊接和制造公司的零件。但更重要的是,由于部件对镀铬,因此不够清洁,因此镀铬并不粘附在气体尖端上的螺纹上不够干净。

琼斯听说过超声波的机器,并称为公司。Lisa Serafini是一家技术销售代表,带有Freeport,Ill。公司,然后为ushers做了一些零件测试。

超声波测试

“我在不锈钢洞穴,核心和轴承上进行超声波零件测试,”她说。“零件被水垢和油覆盖,这些污染物需要从另一个制造过程发生之前从零件中取出。”

Ultrasonic Power Corporation has manufactured ultrasonic parts washers in Freeport since 1972, and their standard product line offers capacities ranging from one- to 204-gallon systems, including ultrasonic immersible transducers and generators as an economical solution for retrofitting existing non-ultrasonic cleaning equipment.

The system has custom multi-stage clean, rinse and dry systems that are available to fit application-specific needs, Serafini says.

“我们在我们的设施中制作发电机和传感器,”她说。“我们从不从另一家公司近海购买超声波成分,然后在我们的名字下组装它们。”

此前,员工的员工用丝刷用丝刷用手工清洁零件,然后用腐蚀剂洗涤剂在垫圈中用腐蚀性洗涤剂。每天约250份,该过程需要太多的体力劳动。

5-7 Minutes Wash

Serafini says the testing was done using a bench-top ultrasonic parts washer with Brulin 815GD detergent at a dilution of 10 percent per gallon at 140°F. The stainless steel parts were immersed in the ultrasonic bath for 5 to 7 minutes, rinsed with warm tap water for a minute, and dried with a forced air parts dryer.

A 204-gallon Ultrasonic Console with Sonic Touch.

When Ushers decided to purchase and install the system, Serafini says the company immediately realized a cost savings with the new equipment.

“Since they no longer needed waste removal of their old chemical, they saved $15,000 in the first year alone,” she says. “The system paid for itself in less than a year. They have since purchased several other ultrasonic cleaners for their other facility locations.”

Jones says his company is cleaning 304 and 410 stainless steel gas tips covered in coolant from machining. The parts are fully immersed in the ultrasonic bath for 20 minutes, rinsed with warm tap water for 15 minutes, and then air dried. The entire process takes about 45 minutes per batch of 30-50 parts.

琼斯说,这与先前的过程相比,这是每批最多需要3小时的手动清洁。由于公司每周最多清理600份,因此节省时间确实增加了。

Better Cleaning

“We knew we had to get a better cleaning process in place,” Jones says. “Using a can of spray just wasn’t getting the job done. Obviously, the time savings is fantastic, but in the end we had to get a clean part before moving on to be plated.”

现在,商店每天通过工厂每天移动大约300份,而不是100年的100。

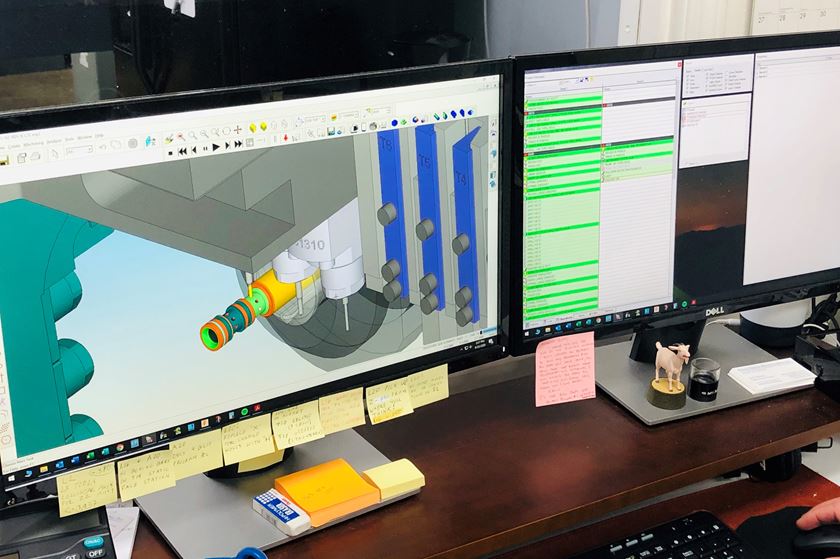

Ultrasonic Power Corp. manufactures its transducers and generators in Freeport, Illinois.

“We could have never done that, especially by hand,” he says.

当它达到大型订单时,这些问题特别明显,或者需要迅速出局的问题。

“When it came to crunch time, we were really in trouble,” says Jones. “It didn’t take a rocket scientist to see what we needed to do.”

Serafini说,她的公司的清洁剂系列使用超声波振动来产生数百万微观气泡,可提供精密加工设备上的最小裂缝的动力。她说,泡沫的真空塌陷后的高能量释放占超声波精密垫圈可以提供的最终清洁水平。

The Ultrasonic Power machines have a patented Vibra-Bar transducer module, which consists of a radiating bar approximately 2 x 5.5 inches that is permanently attached to the stainless steel radiating surface by high temperature bonding. Serafini says that on the radiating bar are two active piezoelectric stacks, which consist of PZT elements bolted between the radiating bar and backing plate.

低耗散

“PZT元素专门制定以获得低耗散,高密度和低孔隙率,这导致改善的性能和可忽略的老化,”她说。

该机器还具有同步多频,Serafini通过在活动堆叠的两个区域驱动辐射杆来完成,这些杆通过从发电机由全波或半波模式调制的发电机的40kHz振荡通电手术。

她说,没有任何堆叠粘合剂允许堆叠振动并不仅在厚度模式中振动并谐振,而且还在其他模式如圆形和横向上。

No matter how the machines work internally, Jones and Ushers Machine and Tool Co. are happy to have it. That’s why Ushers has ordered a newer, larger model that can hold up to 135 gallons of water for a second plant near the main shop.

“It’s been a great addition to our operation, and we’re trying to get leaner all the time,” he says. “It’s turned out to be less expensive to operate than the way we were doing things, and the result is a better, cleaner part.”

For more information on Ultrasonic Power Corp., call 800-575-0168, or visit UPCorp.com