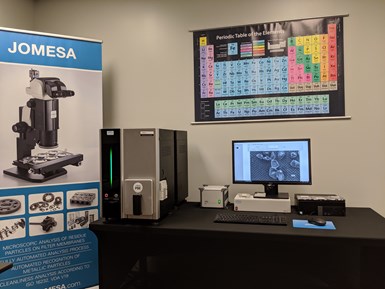

Jomesa’s product line includes the HFD Optical Analysis System; Precision Scan for Elements – SEM/EDX Analysis System; filter membranes for cleanliness analysis; and filter membrane handling and archiving solutions. Photo credits: Jomesa North America Inc.

Contact:

Featured Content

248-457-0023

Mission Statement

It is our mission to deliver the highest quality automated microscope systems and cleanliness analysis accessories to the world of manufacturing.

About Us

Since delivering our first automated microscope system for particle analysis in 2001, Jomesa has grown to be the leader in automated cleanliness analysis microscope systems in accordance with ISO 16232, VDA19.1 and many other company-specific standards. Jomesa operates globally and has direct representation in all major automotive manufacturing markets. Jomesa offers optical and SEM automated analysis systems as well as high quality filter membranes and accessories for use in the cleanliness analysis process.

Our Team

Jomesa employs approximately 100 people around the world, spread across our six global offices. All engineering and product development takes place in our Munich, Germany, headquarters. Accessory production takes place in Munich, as well as Shanghai, China.

Our Products/Services

- HFD Optical Analysis System

- Precision Scan for Elements – SEM/EDX Analysis System

- Filter membranes for cleanliness analysis

- Filter membrane handling and archiving solutions

Awards and Recognition

- World leader in cleanliness analysis microscope systems

- ISO 17025 accredited for Particle Standard certification (first and only lab in the world)