如果您想改进某些东西,请测量

这家商店涉及所有员工的日常工作,分析时间在哪里。

“ rpm”通常代表每分钟旋转,但在楔制造中,这也意味着“从机器上卸下零件”。这是阿拉巴马州伯明翰的浪费时间的各种潜在来源之一。

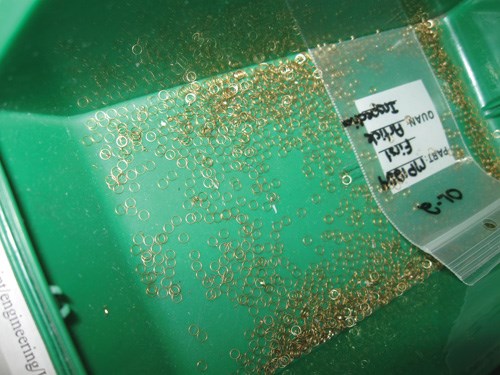

直径为0.063英寸的垫片和在车床上加工的0.003英寸厚的垫片确实产生了很高的RPM时间。这些零件在芯片中丢失,使操作员很难发现和检索。将这个问题确定为明显的浪费时间来源,将商店的注意力集中在

implementing a solution. The particular remedy the shop found was classic lean manufacturing—simple but effective. The shop cut a plastic container to size and bolted it beneath the lathe’s tool slide, where the machine could advance it into position just as the spacer was being cut away.

特色内容

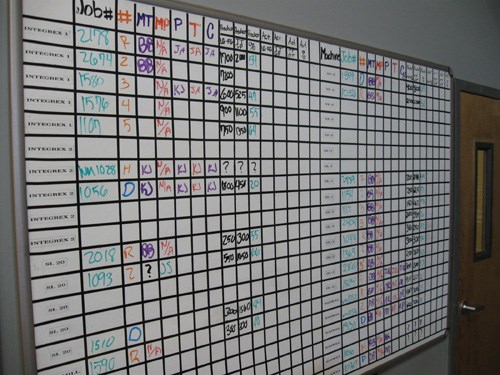

除了此“ RPM”步骤外,Wedge还考虑了过程的其他各个步骤,包括检查零件,与工程进行通信以及获得工具。所有在所有方面都会跟踪九个常见的过程步骤(尽管特定列表频繁地进行了细化)。每天都在每个Shoploor员工中研究这些步骤中的每个步骤的时间。每天下午5:30,商店的工作人员聚集在白板前,当天将这些数字输入这些数字。

没有时间来制作好零件,没有时间的责任。车间不一定享受每天不断的工作量。但是,有审查要查看最大的时间损失的地方。由于没有标准产品来提供标准措施以确定这些损失,因此该“问责委员会”是商店发现的最佳解决方案,可确定正确的方法来改善流程。

董事会工作了。每天花时间来见面和谈话似乎本身就是时间损失,但事实证明,每日会议是商店已经到位的最一致的生产力学科之一。这次每日聚会使每个人都可以清楚地看到效率低下的地方,而不是让每个员工独自猜测他或她的时间是否被很好地使用。将每个人聚集在一起还汇集了经验和见解,为员工提供了一种简单的方式,可以为其他员工面临的挑战提供解决方案。

董事会中衡量成功的列仅标记为“%”。这是生产优质零件所花费的总时间,即每天在每台机器上可用时间的百分比。该商店的目的是看到这些百分比继续攀升。虽然最初在90年代获得数字的梦想已被证明具有挑战性,但商店通常会达到70。如果没有董事会的专门显示如何每天变得更好,那么这些数字将保持良好的状态,甚至没有商店,甚至没有商店意识到它的时间就会降低。在效率低下的过程中,繁忙的活动伪装成生产力 - 通过使生产力变得轻松,精益过程成功。

Going Solo

The idea that lean manufacturing does not apply to job shops is a particularly ironic notion to Wedge, because this manufacturer didn’t embrace lean until it became a job shop.

该商店始于IMS部门,综合医疗系统 - 伯明翰公司,除其他服务外,还提供了手术器械的维修。IMS对供应商收到的一些加工工作不满意,建立了自己的机械车间。起初,该商店仅由一个加工中心和一台Mazak Integrex多任务机器组成,并拥有两名员工来运行它们。

那时没有紧迫的需求。两名员工可以继续进行持续的沟通,并轻松查看他们必须采取哪些步骤来完成当天的工作要求。两台机器也很容易直接安排。

但是,机器和人员的数量增加了,甚至更大的是,IMS看到了通过外部销售加工服务来赚取收入的机会。因此,该部门分开和搬迁,以2007年的楔形制造开放。其专业是小精确零件。

Today there are 14 employees and 10 CNC machines, consisting of two machining centers, two Integrex machines, one Swiss-type lathe, three other lathes and two EDM machines. Instead of being committed to just one internal customer, the shop now has about a dozen customers in addition to its corporate owner.

当布莱恩·琼斯(Brian Jones)被聘为Wedge的总经理时,他为其他制造商带来了工作的背景。他采取的第一步之一是将所有员工送入奥本大学进行的“精益101”培训的一天,因此,整个员工都会对精益目标及其学科的目标有所了解。该指令很快就会进行的更改说明了“精益”一词实际上是错误的,因为商店添加了资源与将它们带走一样多。

Collets were purchased in the interest of saving time, for example. Every turning machine got its own complete set of collets so operators would not have to look for them. But then, Allen wrenches were subtracted—also in the interest of saving time—with each machine not having a full set, but instead only the wrenches that could be used on that machine.

甚至更多的视觉效果

Other process changes have resulted from employees’ daily discussions around the board. One of the most significant of these was a second whiteboard that now summarizes the upcoming jobs for each machine. Having this information available in such a visible way has enabled employees to use their unplanned free moments more effectively. At a glance, employees can now start thinking about the jobs they’ll run next. While the current job is running, they can examine the travelers and setup sheets stored in a rack near the whiteboard and begin assembling the tools, gages and other resources needed to start work on that job when the machine becomes free.

通过这样的创新使过程变得轻松,最终增加了容量,因为员工的时间和机器时间不再因效率降低而失去。因此,楔形制造业中最重要的节省收益与不必支出的支出有关。这家商店以前认为,它可能需要更多的设备来满足他作为车间的第一年或更多员工的需求,但是它通过变得更好而找到了能力。

现在,当新设备和新员工来的时候,商店将以更好的条件添加它们。随着业务扩大到需要这些新资源的程度,商店对精益的关注将使它能够比其他知识更具知识。由于它每天都关注其现有流程的性能,Wedge将能够从将来基于这些过程所采取的步骤实现更大的价值。

相关内容

商店的库存控制系统

An ongoing effort towards more efficient operations drove this shop to take a closer look at indirect material usage, subsequently leading to implementation of a new system for tracking toolroom inventory.

提高生产率的五种选择

Today’s market is more competitive and time-driven than ever, and seemingly small workflow improvements can often result in huge gains in the medium and long term. Accuracy and throughput can be greatly increased simply by choosing the best tool for the job.

The Pursuit of Perfection

The “Pursuit of Perfection” is how Acero Precision defines its mission and while such lofty words make nice copy, all one needs to do is visit this contract manufacturer to experience how serious the company is about the technology, personnel and processes necessary to make it more than an abstract goal.

.jpg;width=70;height=70;mode=crop)