How To Machine Aircraft Titanium: Getting The Metal Out

加工上的一系列文章的一部分的口袋in titanium parts, this article describes various options for roughing the hard metal efficiently.

The article at right about the 8-to-1 rule describes using end mills with many flutes to take fast finishing passes in titanium pockets. But what about roughing the titanium? If the component is machined from a solid block, then all of the rough stock has to be hogged from the pocket before the 8-to-1 technique can be applied.

Cutting tool supplier Sandvik Coromant has a research group devoted to aerospace machining. This group has worked to develop and evaluate techniques for efficiently machining titanium aerostructure components. Bruce Carter, aerospace projects manager with the company, says when it comes to roughing, there are essentially three options for hogging material out of a titanium pocket. They are: (1) drilling and profile milling, (2) ramping to incremental depths, and (3) drilling and plunge milling.

他说,其中的第一个是最富有成效的选择。另外两个解决了更困难口袋的挑战。

钻孔和外形磨机

这种方法开始于钻孔口袋里的大直径启动孔开始。对于芯片间隙,钻孔孔应尽可能大,最小,1.3或1.4倍的铣削工具的直径,将粗略地区的其余部分。然后,粗糙的铣刀应尽可能深入地钻孔 - 留下约0.20英寸的库存,以便在以后完成地板(下面更多)。从钻孔开始,铣刀向外前进,以在一组通道中铣削口袋深度。右编辑器选择下的视频动画显示了铣刀从孔中进入材料的最佳方式。

卡特先生说,这种方法代表了钛的口袋里的最富有成效的材料去除过程。然而,它需要一个相对简单的口袋形状,这些口袋形状没有任何轮廓或特征,这需要在口袋的某些部件中更换工具或加工连续层。这种方法还需要一个稳定的过程,这意味着口袋应该相对较浅,并且工具悬垂应不超过4倍直径。当口袋不浅,或者由于其他原因缺乏僵硬时,其他两个选项中的一个可能更有效。

Ramp And Interpolate

This approach does not require a drilled hole. It uses just one tool. This is a milling cutter that ramps into the material and interpolates to machine one layer of the pocket before ramping to the next layer. Depths of cut are light, which may make this technique best for less-rigid machines such as some 40-taper machine tools. The technique can be used with a high-feed mill, but a milling cutter with circular inserts can ramp more aggressively.

The approach can be much more effective than the previous technique for pockets that have varying depths resulting from a contoured shape.

Drill And Plunge

This technique is a problem solver, Mr. Carter says. Just like the first technique, this one begins with a drilled hole. However, from there, the machine essentially keeps on drilling—making overlapping plunges with a plunge-milling tool or a drill capable of machining this way. The Z axis is generally the stiffest axis of any machining center, so this technique can allow pockets to be machined in titanium even on machines with poor rigidity. It also offers an excellent way to machine deep pockets requiring tool overhangs of 4 times diameter or more.

Of course, one drawback of this machining technique is the cusps that are left between plunging passes all along the outline of the pocket. These have to be removed in a separate operation.

角落问题

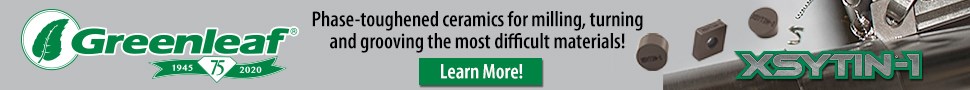

The first two techniques—drill and profile mill, and ramp and interpolate—share a common problem in the corners. Making a right-angle turn to machine an internal corner produces a dramatic increase in radial depth of cut. This can lead to excessive tool wear, tool breakage or unacceptable chatter marks in the corners—not to mention an unpredictable process that is difficult to leave unattended. Therefore, the solution Mr. Carter recommends is to have almost no corners at all. Specifically, instead of milling parallel to the walls of the pocket, he says to mill outward in circles until the walls of the pocket actually do have to be machined in straight lines.

A drawing at right illustrates this. The constant-arc tool paths allow the process to maximize both chip load and radial depth of cut because the load on the tool remains steady throughout this spiraling path. The feed rate may change to allow for more abrupt changes in the toolpath direction as the cutter reaches the wall—but even here, the tool should make large-diameter arcs that steer well clear of the internal corners.

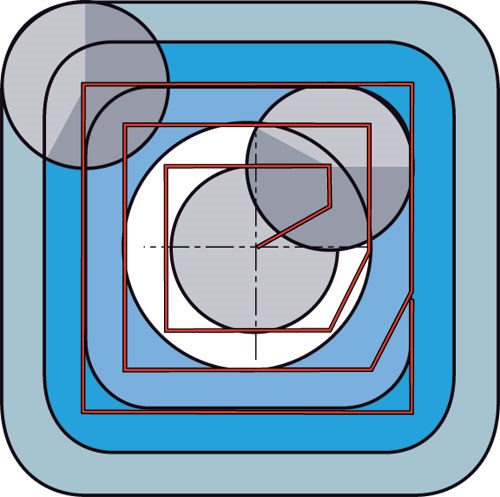

那么,应该如何移除角落中的剩余粗糙库存?卡特先生暗示了一种技术,即桑太科调用“切片” - 在上述三种存档技术中任一项的包装技术之后也可以应用于拐角中的材料。

Slicing

切片是一种半精加工技术,其中材料通过一系列越来越较短的弧形从角落中除去,以降至较小的角落半径。右边的另一个绘图说明了这一点。

As the drawing shows, each arc permits a light radial depth of cut. The light pass can be taken at a relatively high feed rate. However, the radial depth increases as the tool gets closer to the corner, so the feed rate should decrease accordingly.

最后,这留下了一个略大于工具的角半径。这不是整个角落的方法;暴跌和扫描是一种技术(参见右边的文章)。

切片技术不仅适用于直角角,而且还适用于更急剧的角落。急性角落只是需要更多的切片通行证来扫除粗糙的股票留下的额外股票。

The Floor

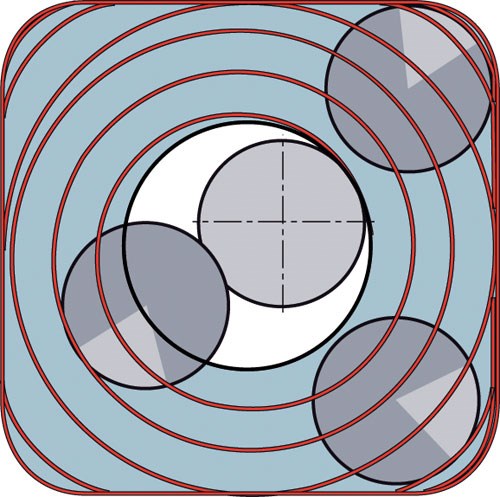

将材料从口袋中获得材料的最终重要考虑是地板(与

口袋的墙壁可能会铣削到其最终尺寸。然而,整理地板涉及更多库存删除,而许多商店用于考虑完成通过的一部分。

卡特先生说,在口袋的地板上留下0.20至0.25英寸,是铣削钛飞机部件的良好做法。随着材料加工,此库存的股票可帮助支持薄层抗振动。

为了确保切割稳定,袋的地板被加工到从钻孔辐射出来的环中的成品深度。因此,切割始终在其旁边具有未加工的库存,以提供支撑 - 一直到支撑件来自相邻壁的位置,其本身将稍后完成,可能使用先前描述的8到1条规则。

编者注:您可以通过单击读取下一个(向右)阅读本系列中的其他部分。

RELATED CONTENT

建筑物是空的填充箱

Over the past decade, technology has advanced to the point that lights-out machining is more seamless than ever before, with built-in safety systems and even the ability to switch from one part to another in the middle of the night.

Tooling up for Micromachining

Choosing the right tools and matching them to the correct operations and process techniques for micromachining applications is critical to success in this burgeoning market.

Machining Exotics

Production machining has changed from large runs of parts carved out of free machining materials to smaller runs of parts from much more difficult to machine materials. Learn how to adjust to this challenge.

.jpg;width=70;height=70;mode=crop)