更高效的生产从Swiss-Ty怎么走吗pe and Multitasking Machines

用于多轴瑞士类型和多任务机的SolidCAM提供了非常有效的CAM编程过程,生成了最佳且安全的铣削程序,并具有巨大改进的铣削工具寿命。

#水平和垂直路线

近年来,近年来的一个很大的趋势是迅速采用磨坊设备,例如多轴瑞士型机器和较大的多任务中心。使用“一对一”方法,可以在单个设置中产生非常复杂的零件。但是,许多商店的机器不足,因为它们可能难以编程,并且CAM系统在支持此类设备上的高级铣削技术方面速度很慢。这迫使商店在其昂贵的瑞士和多任务机器上经营更高的地块工作,效率低下,比必要的周期时间更长。

请参阅瑞士和多任务机中的SolidCAM高性能转弯。

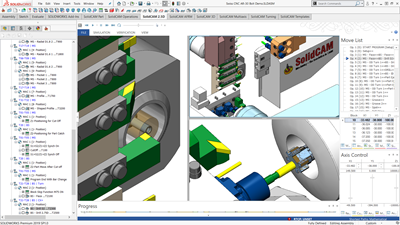

CAM developer SolidCAM has an answer for this with its intelligent iMachining toolpath generator, driving and protecting even the smallest tools effectively, on these advanced Mill-Turn and Swiss-type CNC machines. The CAM system combines advanced multitasking programing functionality, integrated channel-synchronized simulation, and state-of-art milling capabilities, all integrated into a 3D CAD modeling platform. This enables shops to generate production-ready part programs with reduced cycle times much faster and more easily via better management of simultaneous operations and more efficient milling routines.

Dr. Emil Somekh, the Founder and CEO of SolidCAM, emphasizes that one of the important benefits that SolidCAM provides its users is the ability to run inside the popular CAD systems SOLIDWORKS and Autodesk Inventor. This gives shops no-compromise 3D modeling capabilities while eliminating all file transfer issues which are present when working with standalone CAD and CAM systems. You can work back and forth between design iterations and creating toolpaths, with full associativity of the toolpath to the updated design model.

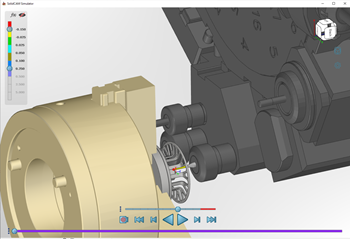

SolidCAM Simulation brings your Mill-Turn to life.

This no-compromise philosophy becomes even more apparent in the CAM programming process. With many CAM systems, programmers must build a multitasking program operation by operation, and then wait to see a full simulation on another application. With SolidCAM, simulation is completely integrated within the programming process. The ability to fully visualize a machine preview at each step of the programming process is a faster, safer, and more effective way to generate validated code. SolidCAM also takes the simulation to the next level by simulating synchronized channels throughout the process. This enables programmers to balance simultaneous operations more easily, generating efficient programs, avoiding collisions, and ultimately generating a ‘first-part’ perfect output. The net result of all this is to generate safe and efficient programs, for even the most complex parts, in the shortest possible time.

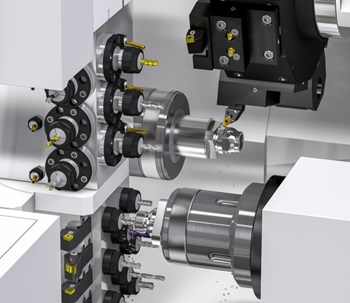

SICECAM用户机器在STAR SWISS CNC上的医疗设备。

最先进的铣削是多任务机

As progressively more complex milling is being done on what were once thought of as turning centers, the ability to execute those milling operations efficiently grows more important by the day. Multitasking machines are expensive, and they typically don’t have a large tool capacity. To get the most out of their investment, shops need the ability to compress machining time, yet extend tool life as much as possible, and that’s what iMachining does. Dr. Emil Somekh attests to the fact it can reduce machining time by 70% or more AND increase tool life by as much as 10 times. That’s a big claim, so let’s examine how it works.

Multiple Channels of Advanced Mill-Turn on a QuickTECH CNC.

iMachining employs advanced high efficiency milling to reduce cycle times, using solid end mills, small stepovers, faster feed rates and deeper axial depths of cut. The key to achieving the highest possible metal removal rates is to generate optimized morphed spiral tool paths, with variable cutting angles and feed rates at every point of the toolpath, so that there is a constant spindle load. This avoids the shocks that occur when material engagement changes abruptly, for example, when a tool hits the corner of a pocket. Without this capability, you must manage feed rates for the worst-case cutter load scenarios, making cycle times much longer than necessary. Moreover, maintaining a constant spindle load substantially reduces vibrations, thus yielding dramatic increases in tool life as well as better surface finishes.

使用小直径工具铣削时,这种能力在瑞士机器上特别有用。SolidCam的客户通常会在整个切割深处使用0.015直径的端钻,甚至可以根据控制互动角(Radial Doc)的方式来容纳较小的工具。

SolidCam用于所有受欢迎的瑞士型机器,包括公民,Star,Tsugami,Miyano,Ganesh,Ganesh,QuickTech和Nextern,并配备后处理器。

Equally important for Swiss and many other multitasking machines, SolidCAM includes Virtual Machine ID (VMID) which enables part programs to be tailored to a specific machine. This allows users to define electromechanical elements of the machine such as maximum spindle horsepower, speed and feed rates. This enables optimum milling routines of how fast or how much horsepower a spindle may have.

如何实现最大的工具寿命

iMachining has been shown to not only give better Material Removal Rates (MRR) than any other toolpath technology, but also amazing increases in tool life... Most people assume that, since iMachining is more aggressive with the cutting speeds and feeds, that it should wear out the tool sooner. So how is it that iMachining provides much better tool life?

SolidCam获得的专利用于磨坊的iMachining可提供最大的材料去除和更长的工具寿命。

要了解这一点,我们必须首先了解固体碳化物切割机。碳化物是一种极其硬的材料。它可以应对大多数其他材料以外的压缩力,并且对磨料具有很高的耐药性。这些因素使其成为切割工具,用于切割钢,超级合金和大多数其他金属的绝佳材料。除了非常艰苦的情况外,碳化物也非常“脆” - 它根本无法很好地掌握拉伸力(弯曲力)。

放弃可确保固体碳化物工具锋利边缘的碳化物底物从未看到拉伸力 - 它只能看到压缩力。因此,锋利的边缘也抵抗了微芯片,即使在较高的性能水平上,随着消毒的效果升高,从而促进了工具寿命的显着改善。

增加工具寿命的另一个重要因素是能够以其完整的切割深度运行工具。过去,为了避免对脆性工具施加太大的压力,其他系统只会削减较浅的削减以弥补过度参与。随着移动性,利用工具的完整切割深度永远不会过度强调它,并实际上将力传播到更大的区域,从而通过使用长笛的全长而不仅仅是底部10%,从而进一步最大化工具寿命。

SolidCam强大的高级磨坊和瑞士型解决方案。

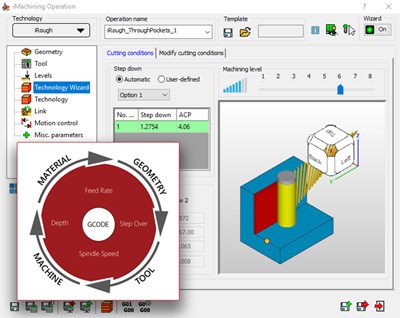

消毒技术向导

With SolidCAM's iMachining Technology Wizard you choose your level of aggressiveness and the Wizard does the rest.

Since SolidCAM’s iMachining Wizard uniquely and automatically calculates optimal feeds and speeds, taking into account the cutting tool, stock material and machine characteristics, this guarantees ‘first-part’ success, without time consuming, extensive trial and error to determine optimal cutting parameters. The iMachining Technology Wizard removes practically all of the guesswork involved with setting the machining parameters.

Imachining具有内置的智能,以确保2D和3D消毒中每个零件几何特征的最有效的铣削刀具路径。消除2D可以处理棱柱形零件的粗糙,半虚拟和饰面。Imaching 3D用单击,高效率的过程取代了复杂3D形状的多个标准粗糙和半精细操作。节省的编程时间令人惊叹。

For twin turning spindle machines, the Machine Control Operation (MCO) function takes the worry out of synchronizing part transfers and pick offs. Programmers just enter the necessary parameters and SolidCAM does the rest.

与所有iMachining自动化,唯一的广告justment most users make is with the iMachining level slider that controls how aggressive the operator wants the machine to remove the material. “Imagine putting the knowledge and experience of hundreds of CAM and CNC masters in the palm of your hand. Experience the iMachining Wizard and Tool Path!” says Dr. Somekh.

高级工具桌用于磨坊和瑞士

SolidCAM’s new advanced tool table enables intelligent managing of the tool posts, with predefined tool assemblies. Multi-body tool components provide precise collision detection and flexible tool assembly changes. Special functionality for Swiss type enables direct entering of tool setup values to SolidCAM. Angle head attachments with rotary axes, can be directly managed from the tool table.

包括微型转弯工具在内的任何类型的3D切割机的支持,使用户能够具有精确的碰撞控制。

Multi-Channel Synchronization

The SolidCAM Mill Turn and Swiss advanced Multi-Channel Synchronization specializes in factoring in the CNC machine kinematic limitations, and the controller limitations, when doing the synchronization of parallel multiple tasks. All the extensive info about the CNC machine, including the above-mentioned limitations, are defined in the Virtual Machine ID, which is the Digital Twin of the actual CNC machine. The intermediate simulations perfectly reflect the results of the Multi-Channel Synchronization.

SolidCAM's entire process from CAM to cutting on a Swiss Citizen CNC.

The user interface of the SolidCAM channel synchronization has dual modes: the first is a time-based Gant-like picture that gives the overall timing of the piece. The second is operation-based, giving the user the complete picture of the operations after synchronization. Seeing both output modes gives the user a very clear understanding of the synchronization execution.

SolidCam的仿真使您可以通过过程的每个步骤可视化CAM编程。

The Swiss solution automatically activates machine kinematics superimposition and master-slave axes modes, eliminating the need for the user to manually activate these modes. Smart logical crash detection, clearly showing the problem to the user, assists him to do the necessary synchronization changes to solve the problem, long before any machine is compromised.

According to Shaun Mymudes, SolidCAM, Inc’s COO: “A major factor in the successful implementation of SolidCAM’s solution, is the advanced technical and postprocessor support of our experienced team.” Summing up, SolidCAM for multi-axis Swiss type and Mill-Turn multitasking machines brings together multiple technology advancements, to optimize the whole process of CAM programming of these complex machines.

For more information, please visit atsolidcam.comandforum.SolidCAM.com。