How Do You Maximize Tool Life In Aluminum?

Boeing experts say climb vs. conventional is not the key. They recently answered a question submitted through our Aerospace Machining Zone, saying the key to tool life is actually chatter control.

Personnel from Boeing's Research & Technology group recently answered readers' questions. One reader asked the following.

Question

Featured Content

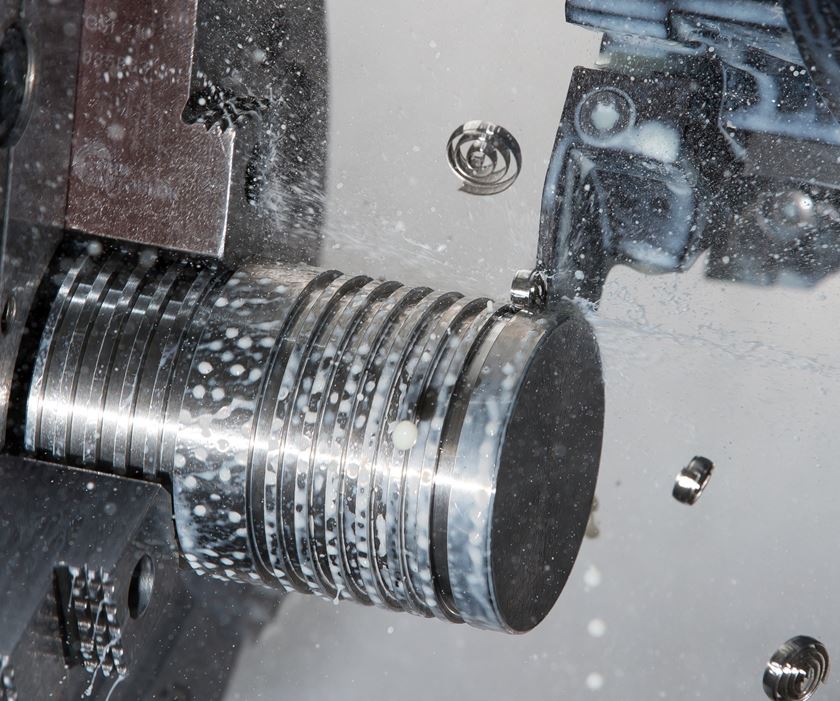

I am roughing Al 7000-series material at around 30,000 rpm using a 1-inch solid carbide uncoated end mill with 2 flutes at an axial DOC of 0.200 inch and a radial DOC of 50%. I am using an HSK80 toolholder, coolant through, with a good machine and stable setup.

At this speed, there is no surface finish difference if I climb or conventional mill. But is there a difference between the two methods in terms of tool life?

Response from Boeing’s Research & Technology group

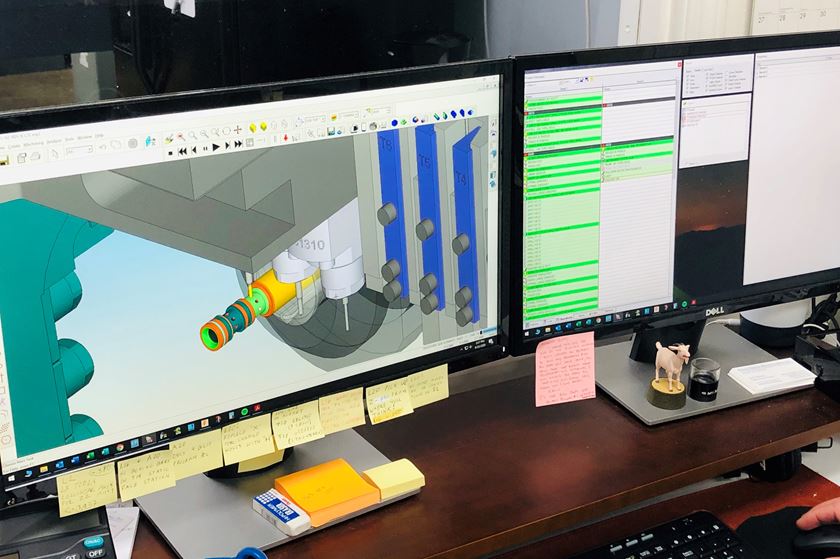

With 7000-series aluminum on our own 24,000-rpm spindle, we achieve 200+ hours of tool life using carbide cutters. We do both climb and conventional milling and we do not see tool life being affected. For us, the key to long tool life and good part finishes is dynamically testing all of our cutting tools first before high speed machining aluminum. By doing so, we find what is called the "sweet spot," which is the optimal rpm and depth of cut the cutting tool will run with no chatter regardless of step-over, full slot cutting or corners. Once we have these parameters, we program to them—confident that we will not have any cutting tool chatter issues. The system we use for this dynamic testing is called "Metal Max” from Manufacturing Laboratories, Inc.

RELATED CONTENT

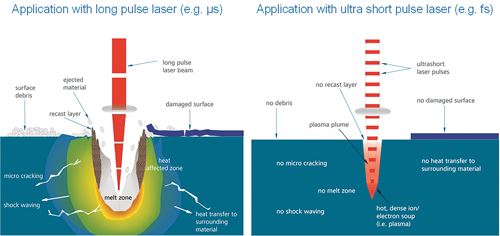

Cutting a Micron at a Time

When the task is to remove very small amounts of material, this process may be the answer.

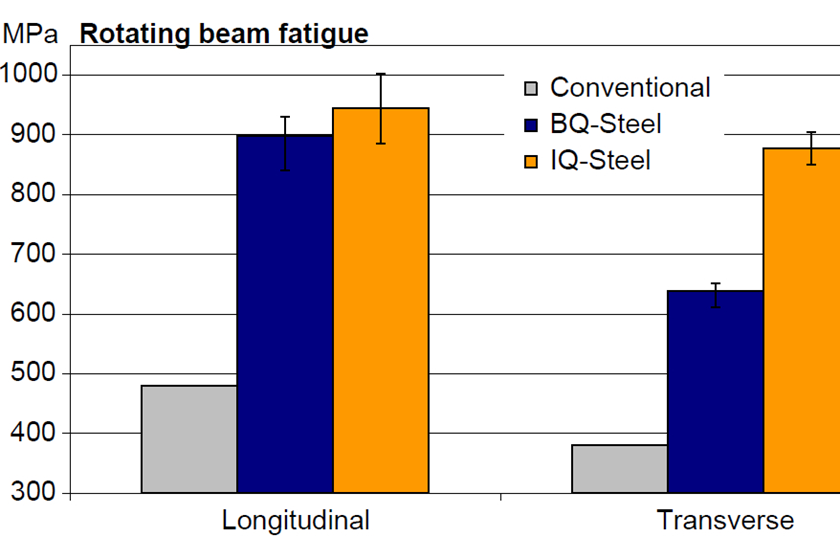

Consistency with Indirect Extrusion

A return to basics, paired with extensive research, proved instrumental in the enhancements of this aluminum rod and bar manufacturer’s product line.

Good Investment Casting

An increasing number of shops that make metal parts that are intricate, require extensive machining or are produced repetitively or in limited quantities, are finding that investment casting is the ideal solution.