CNC多翼圈的进步如何使您领先于当前趋势

Growing economic and labor pressures are making CNC multi-spindle turn/mill technology more viable than ever. This real-world comparison to a single-spindle lathe shows how.

Amidst global events that have shaken the world’s economies, American manufacturers face a range of challenges both new and familiar. The actions taken to overcome these hurdles will vary from company to company. For those who produce medium-to-large lots of parts 2" or smaller in diameter, the most impactful solution may lie in the adoption of advanced CNC multi-spindle lathes.

你不是一个人

It’s no secret that manufacturers have a lot to deal with.

熟练的劳动力短缺一直是当今行业中工作人员的大部分生活的关注。过去两年的提前退休和中年职业变革的双重浪潮加剧了这一趋势,使公司更难招募和维护他们成长所需的团队。

Sporadic supply chain issues have arrived in waves as countries vital to the world economy have instituted lockdowns in efforts to protect their populations. Each has added to the others, rippling out to create a state of persistent disruption that has been further aggravated by war in Europe.

最后但并非最不重要的一点是,通货膨胀引起了多个国家,这是由于两年的储蓄和需求超越供应的驱动。这给每个制造商带来了与成本相关的压力,因为客户抵制价格也会提高,即使供应商要求它们。

好消息是,你并不孤独。每一个你ur competitors is facing down the same host of issues. By identifying and implementing strategies to adapt, you can carve out an advantage that will lead to long-term growth.

The State of the CNC Multi-Spindle

So how can CNC multi-spindles help manufacturers gain an edge? To answer that, one needs to first understand how this machine technology has evolved over the past decade.

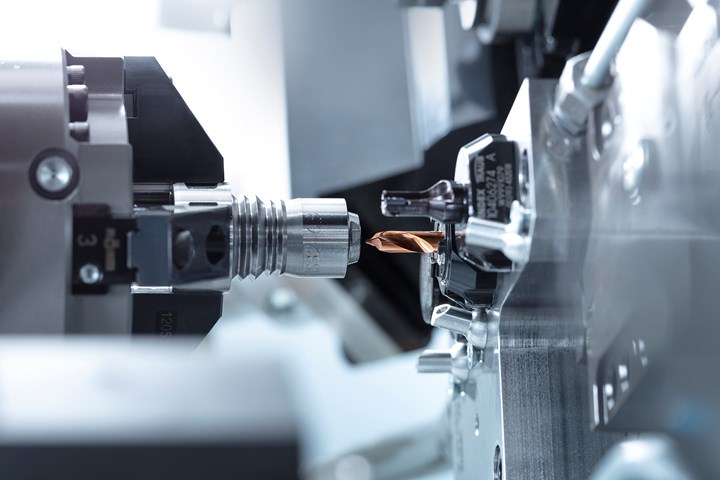

通过同时在多个主轴上执行不同的工件操作,可以大大减少机器周期时间。

Historically, multi-spindles were sometimes viewed as rather inflexible solutions. If you had steady demand for a very high quantity of a fairly simple part or family of highly similar simple parts, you might consider a multi-spindle. It could take a significant amount of time to iron out the process and get it set up, but once it was running, the machine could produce parts dramatically faster than competing technologies.

当今的CNC多主轴在速度方面具有相同的优势,但具有更大的灵活性。

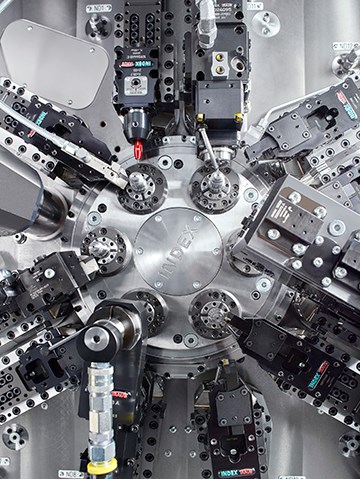

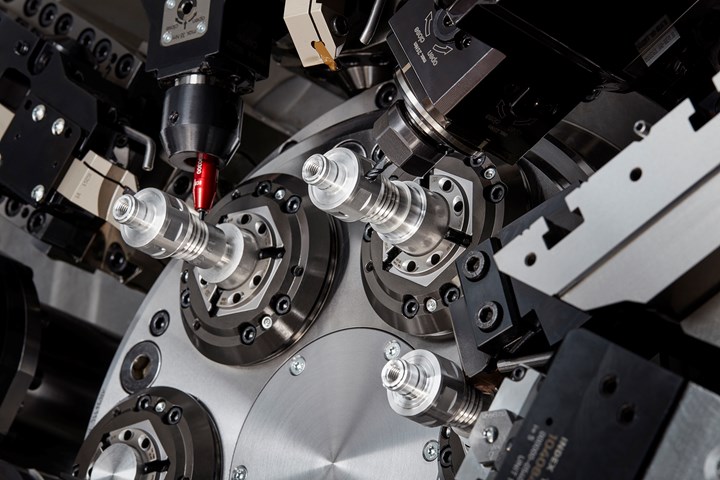

AtINDEX, for example, all current generation multi-spindles incorporate a modular system. Whether looking at a 6-spindle or 8-spindle machine, each spindle is served by two tool slides that can quickly and easily be swapped out. Slides can hold static or live tools, and can be equipped with C and Y axes, in addition to the standard X and Z axes. This flexible, modular approach opens up a lot of possibilities.

当前的Gen Multi-Edspindles可以使零件更复杂。除了典型的转弯,铣削和钻井操作外,这些机器还可以执行更多专业的过程,例如偏心钻孔,螺纹,轮廓,轮廓,滚动和多边形转弯。此外,机器可以配备一个或两个后处理附件,从而使高度复杂的零件完全切割,而无需辅助处理。

Modern multi-spindle technology can perform almost any turning and milling task, all under CNC control.

模块化方法还简化了转换。索引使用专利的W交换定位系统,该系统允许用户简单地松开固定螺钉并卸下当前幻灯片,然后放置新的幻灯片并拧紧其固定螺钉。W-Serration系统可以自动确保使用µM精确比对。随着较旧的多管束,机器上的变化意味着遭受重大的停机时间。新系统允许从机器上预设工具,然后进行令人难以置信的快速转换。这使制造商可以在机器上经济运行相对较小的地块,从而将技术的好处带入了较宽的零件。

Lastly, advancements in software have greatly simplified the programming of a CNC multi-spindle. In reality, the difficulty of programming these machines was overstated in the past. After all, essentially a multi-spindle user is just programming either six or eight individual lathes, with much of the complexity stemming from the need to equalize processing time as much as possible across the spindles. But with software like索引的虚拟机,创建和优化零件程序变得非常有效。

In short, the evolution of multi-spindle technology has made it applicable to a far wider range of parts and applications. Many shops that would not have been able to benefit from a multi-spindle at the turn of the century could achieve significant gains by adopting the technology as it exists today. Let’s take a quick look at an example from one who has.

Real World Impact

Producing this helical pinion gear on a multi-spindle generates nearly 12 times the profit compared to a single spindle lathe.

该螺旋齿轮用于差异传输段,用于从15MNCRS5钢合金加工。它的直径为0.79英寸(20毫米),长度为0.98英寸(25毫米)。在索引MS24-6多主轴上,周期时间仅为11秒。在单轴车床上,是38秒。

For this comparison, let’s assume an order for 20,000 pieces at an even price of $1.00 per piece.

To start our comparison, we look at how long it would take the two machines in question to complete the job. We’ll assume a 5-day work week with the machines operating 20 hours per day.

单轴车床 |

MS24-6 Multi-Spindle |

|

总数(量 |

20,000 |

20,000 |

Cycle time (seconds) |

38 |

11 |

完成工作的小时 |

211.1 |

61.1 |

Days to complete job |

10.6 |

3.1 |

接下来,我们将计算两种情况的计算机部分。

单轴车床 |

MS24-6 Multi-Spindle |

|

大约价格 |

$ 500,000 |

$1,785,000 |

Finance period (months) |

84 |

84 |

Interest rate |

5.75% |

5.75% |

Monthly payment |

$ 7,245 |

$ 25,863 |

Annual total of monthly payments |

$ 86,934 |

$ 310,354 |

% of year allocated to job (days to complete job / 250) |

4.2% |

1.2% |

机器部分工作成本 |

$3,671 |

$3,793 |

最后,我们需要添加商店费率,以考虑机器之外的开销。这个数字可能会有很大差异,但是60美元是平均价格。通过插入它,我们可以确定两台机器下作业的盈利能力。

单轴车床 |

MS24-6 Multi-Spindle |

|

工作收入 |

$20,000 |

$20,000 |

机器部分工作成本 |

$3,671 |

$3,793 |

工作成本的高架部分(完成工作60 x小时) |

$12,667 |

$3,667 |

净利润 |

$3,663 |

$12,540 |

And just to drive the point home, let’s take a quick look at what the profitability of each machine looks like over the course of the year. For simplicity’s sake, we’ll assume that the shop can win a steady supply of work with ratios that are identical to the above example.

单轴车床 |

MS24-6 Multi-Spindle |

|

年度工作人数(250 /天完成工作) |

23.7 |

81.8 |

每份工作净利润 |

$3,663 |

$12,540 |

Annualized profit for machine |

$86,750 |

$ 1,026,009 |

Put simply, the power of productivity is so impactful on profits that even though the multi-spindle costs more than 3x the single-spindle machine, it generates nearly 12x the profit. In fact, the effect is so dramatic that even if you dropped the cost of the single-spindle lathe to $0, the multi-spindle would still be 490% more profitable to operate.

Are Multi-Spindles Right for You?

如上面的示例所示,对于正确的零件类型,根本没有更快,更具成本效益的生产方法。在当前环境中,优势变得更大。

By significantly reducing per-part costs, a CNC multi-spindle can immediately reduce the stress of pricing pressures. This provides more flexibility to negotiate, both with vendors and customers.

For shops having difficulty finding skilled operators, multi-spindles offer a path to growth within the bounds of your current team. Generally, a multi-spindle requires no more operator intervention than any other type of machine, yet will produce anywhere from 400% to 600% of the output. If labor is constraining your ability to win new work, a multi-spindle can be liberating.

The same holds true for shops butting up against the limitations of their facility size. When a company is growing, but also approaching maximum usage of its facility’s floorspace, something has to change. Many times, a company will opt to purchase a new building or expand an existing one. Conversely, simply replacing several more traditional machines with CNC multi-spindles can grow capacity within the existing footprint, offering the potential for growth with a smaller, more efficient investment.

尽管当前的市场趋势似乎令人生畏,但每个挑战都提供了机会。在过去的两年中,INDEX已经帮助许多北美制造商准确地评估了多主轴技术对其独特运营的影响。如果您想对自己的公司进行此类评估,请联系索引sales@index-usa.com.