Generating More Efficient Milling Tool Paths for Multitasking Machines

该工具路径发电机可以减少周期时间并延长刀具寿命,同时帮助在多轴瑞士类型和旋转磨机上进行铣削操作更好。

#TechBrief

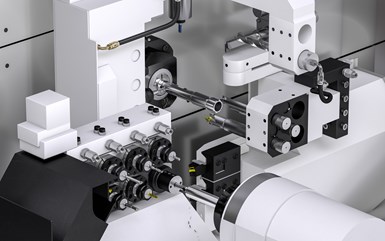

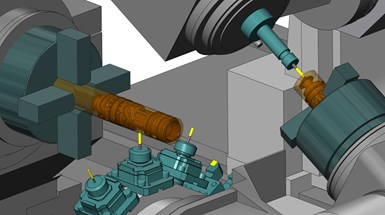

To enable shops to become more efficient with milling operations on multitasking machines,固体车已在公司的CAD/CAM软件中开发了其Imachining Tool Pather Generator。照片来源:SolidCam

Because they offer the potential to machine parts complete is one reason shops are drawn to turn-mills and Swiss-type lathes. And, as part geometry continues to increase in complexity, there are cases in which just as much — if not more — milling is performed on those machines than turning.

To enable shops to become more efficient with milling operations on multitasking machines,固体车已在公司的CAD/CAM软件中开发了其Imachining Tool Pather Generator。据说该工具路径发电机能够将加工时间减少多达70%并增加工具寿命。

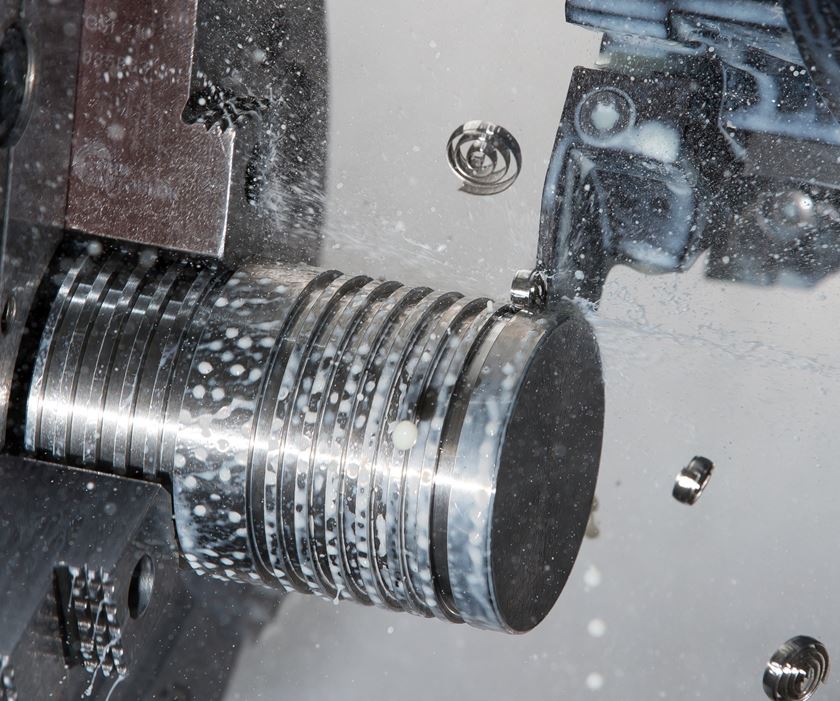

它通过使用高效铣削来减少固体末端磨坊,小步骤,快速进料速率和切割的深度轴向深度来减少周期时间。该公司表示,实现高材料去除率的关键是在工具路径的每个点上都产生优化的,变形的螺旋工具路径,并具有可变的切割角度和进料速率,从而产生恒定的主轴负载。

该策略避免了当物质参与突然变化时发生的冲击,例如工具进入口袋的角落时。如果没有这种能力,则必须对最差的切割器负载方案进行管理率,从而使周期时间更长。此外,保持恒定的主轴负荷会大大减少振动,从而产生刀具寿命的增加以及更好的表面饰面。

能够在单个屏幕上可视化同时操作的能力使得可以使用更快的周期时间构建一个更好平衡的程序。

能够在单个屏幕上可视化同时操作的能力使得可以使用更快的周期时间构建一个更好平衡的程序。

Because multitasking machines are significant investments and might not have a large tool capacity, shops need the ability to compress machining time, yet extend tool life as much as possible. According to SolidCAM, that’s what iMachining does.

One could conclude that because this software is more aggressive with the cutting speeds and feeds that a tool would wear out quickly. But the company says that is not the case. Carbide is an extremely hard material — it can stand up to compressive forces beyond most other materials, and it is also highly resistant to abrasives. These factors make it well-suited for cutting tools used for cutting steel, superalloys and most other metals.

然而,硬质合金也非常脆弱,因此e does not stand up well to tensile (bending) force. The iMachining is designed to ensure that the carbide substrate at the sharp edge of the solid carbide tool flute never sees tensile force — it only sees compressive force. Therefore, the sharp edge resists microchipping, even at elevated performance levels, resulting in improvements to tool life, the company says.

该软件增加工具寿命的另一种方式是它具有使用工具的完整切割深度,同时又不强调工具的能力。它旨在将力传播到大面积上,通过使用长笛的全长而不是只有底部的10%来最大化工具寿命,就像传统的铣削实践一样。

The toolpath generator can be especially useful on Swiss-type machines when milling with small-diameter tools.

该工具路径发电机具有多种自动功能,可提高机器操作员的易用性。例如,其技术向导旨在消除设置加工参数所涉及的所有猜测。用户可以通过使用滑块来调整1到8的尺度,从而选择攻击性水平,从而改变切割数据以实现更高的材料去除,同时留在机器和切割工具的限制内。然后,技术向导会自动计算最佳进料和速度。

Other automatic characteristics include iMachining 2D, which handles the roughing, semifinishing and finishing of prismatic parts. The iMachining 3D replaces multiple standard roughing and semifinishing operations of complex 3D shapes in one step.

The toolpath generator can be especially useful on Swiss-type machines when milling with small-diameter tools. For example, a 0.015-diameter end mill at the full depth of cut can be routinely used. Even smaller tools can be accommodated based on the way that iMachining controls the engagement angle (radial depth of cut).

SolidCAM还提供了其他功能来简化和简化多功能机的编程,例如:

- Integrated simulation.This is said to offer a fast, safe and effective way to generate validated code. Because it simulates synchronized channels throughout the process, it enables programmers to balance simultaneous operations more easily.

- Virtual Machine ID.使用此功能,用户可以通过定义机电元素(例如最大的主轴马力,速度和进料速率)来定制特定机器的软件。

- 机器控制操作。For turning centers with a subspindle, this function synchronizes part transfers and pick offs automatically.

- Toolpost management.工具表启用使用预定义的工具组件来管理工具箱。瑞士类型的特殊功能可以直接将工具设置值输入软件。

- Multichannel Synchronization.Mill-Turn和Swiss Multichannel同步专门考虑计算机运动学限制和同步并行多个任务时的控制器限制。

RELATED CONTENT

Exploring the Benefits of Reaming for Finishing Bores

Reaming与单点无聊相比如何?Reaming工具的供应商比较了这些过程通常用于完成钻孔的过程,并为考虑转向的人提供了技巧。

A New Approach to CNC Turning

This turning process takes advantage of a turn-mill’s B-axis spindle to vary a tool’s approach angle to optimize chip control and feed rates.

热对零件清洁的影响

Thermal dynamics is important for assisting in the cleaning of a part. Adding heat or energy influences the cleaning process through its impact on chemistry, the water within the washer and its effect on drying.