From Aggravation to Lights-Out Production

Automated machining has transformed this South Carolina shop. However, achieving unattended production involved far more than just shutting off the lights.

Dan Hogge says the key to implementing lights-out machining can be expressed in one simple word:

Misery.

Featured Content

You have to see that misery all the way through, he says. If a shop does not have the determination to keep advancing through a period of transition, not knowing when that period will end, then the shop will never fully shift from an operator-dependent process to one that achieves consistent, considerable and bankable lights-out production.

His shop got there. Your shop can get there, too. However, his experience suggests that making this change is liable to be more difficult than you expect.

“Be prepared to be aggravated,” he says.

FROM 70 TO 29

Mr. Hogge (pronounced “hog”) is plant operations manager atHogge Precision Partsin Hartsville, South Carolina. Founded as a screw machine shop by his father, Dan Hogge Sr., the contract machining business transitioned to CNC long ago and now specializes in bar-fed production on multitasking CNC turning centers. Most of its recent machine purchases have been CNC Swiss-types.

The move to unattended production began with the crash of 2007-2008, he says. Hogge Precision Parts was hit hard because its biggest customer was hit hard. The shop’s staff of 70 was cut to 29, and those remaining 29 often saw work weeks as brief as 24 hours.

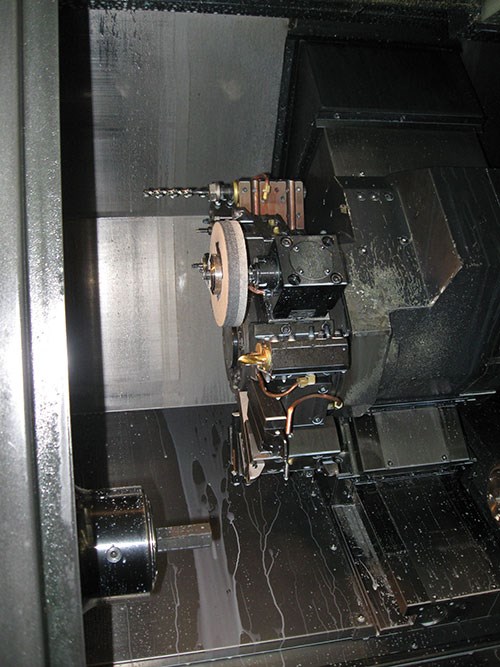

当公共汽车iness began to return in 2009, capacity in the shop’s sole remaining shift filled quickly. That was when a customer came to the shop with an urgent order involving a CNC Swiss-type part. The shop had just purchased its first CNC Swiss-type machine, and while this machine was booked through the day, it went unused at night.

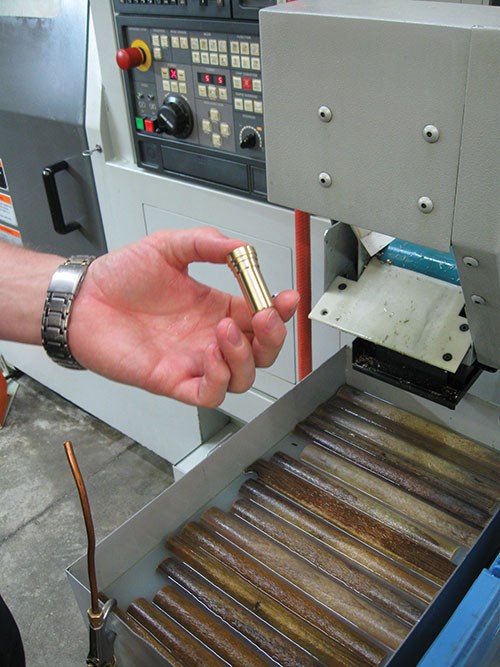

“We thought, why not just let the part run when no one is here?” Mr. Hogge says. Given that the material was brass, there seemed little risk of harm or significant loss if anything went wrong.

And nothing went wrong. The unattended process ran smoothly. The staff arrived the next morning to find 500 finished pieces at the machine. This was the customer’s entire order.

The accomplishment caught Mr. Hogge’s attention. The success seemed to directly address what might have been his most pressing question at the time: how to accommodate rapidly increasing demand without rapidly increasing staffing. Letting go of more than half of the company’s employees had affected the company, and it had affected him. While business activity was high, neither that activity nor the economy itself seemed stable enough to justify expanding the staff. That increase might just be followed by letting a wave of people go all over again. Unattended production seemed to offer a promising alternative.

In retrospect, though, that first attempt at unattended machining might have gone too well, he says. He didn’t know what he was getting into. He committed the shop to realizing lights-out production on various other machines, and that is when the misery began.

PREVIOUSLY INVISIBLE PROBLEMS

He says the obstacle to implementing effective unattended machining is essentially this: Shops do not realize how much they rely on operators. He didn’t realize this about his own shop.

On any given machining process, a variety of infrequent and unpredictable glitches might stop production. Most of these problems are rare. Most are easy to address. In fact, if an operator is present, addressing the glitch might be so easy that hardly anyone even notices a problem arose. But if an operator is not present, then that little problem can cause hours of production to be lost—hours the shop was counting on to fulfill its promises to customers. Thus, the commitment to unattended production proved to be the start of a journey of eliminating glitches.

That is, it was a journey of fixing previously tiny problems that became large, and previously invisible problems that became visible, once the machines started to run with no operators present. The way through this journey was often infuriating, Mr. Hogge says, because successfully resolving a problem that halted production one night could simply reveal another problem that would halt the same process on a later night. Any process on any CNC machine might be susceptible to eight to 10 infrequent production-stopping problems, all of which had to be discovered and resolved before the process could be trusted to run with no employee present.

Again, these were not big problems. A bar feeder loading material into a lathe might fail to trip a switch properly only on rare occasions. By day, the problem went unseen, because an operator noticing that the lathe was not cycling could clear the error and resume production within a minute or two. Something similar might be true of a chip wedging into a strange spot to affect the subspindle chuck, or a cutting tool breaking instead of gradually wearing. While such problems are uncommon, knowledgeable operators spot them and address them easily enough that shops might underestimate how frequently they occur.

Yet even infrequent problems add up. Consider this: If eight potential glitches each stop a particular process only 1 time in 20, the result is a process that will successfully run unattended only two-thirds of the time.

So the shop fixed problems one after another as they presented themselves. What made this time trying was that the way forward was so unpredictable. Success always seemed to have been won until the next problem reared up. When the shop finally did achieve reliable unattended production, the employees didn’t know it. They couldn’t know until they were able to look back on several weeks without a new hang-up having revealed itself. Now, they can report that the journey to realizing effective lights-out machining took them about six months to complete.

PROCESS CHANGES

During that time, here are just some of the ways the shop’s equipment and processes changed:

1.Switches and sensorswere common points of pain. The unreliable handoff from bar feeder to turning center was a real and recurring problem. This was not the fault of the equipment, Mr. Hogge says. Rather, he accepts the blame himself. During the period following the crash, the shop grew lax about maintenance, particularly when imperfections in the equipment seemed so easy to manage. Today, because consistent operation is critical, the company has dramatically changed the way it thinks about maintenance. If the performance of any machine component declines, the shop flags the problem so it can be fixed before it impedes unattended production.

2.Coolant qualitymust remain consistent as well. When this begins to degrade, tool life and part quality suffer. Various machines have now been given individual coolant separators from CoolantGuy.com.

3.Part unloadingis at least as important as how the part goes into the machine. When large production quantities run without an operator to retrieve parts by hand, workpieces falling onto workpieces can cause damage. A workhandling device that prevents this, a device the shop embraced as part of its journey into unattended machining, is the Rota-Rack unloading carousel from Royal Products (see sidebar).

4. What level ofthermal stabilitydoes any given machine provide? Mr. Hogge says the answer might surprise you. His most thermally stable machines have proven to be some of the older ones in the shop. Knowing which machines hold their positioning is valuable for running lights-out, because temperatures change considerably during the course of an unattended shift. As a result of studying this problem, he says the shop now knows more about the thermal temperament of its machine tools than ever before. It knows which machines are stable enough to run the finest-tolerance jobs through the night.

These are just a few areas in which the shop adapted its technology and thinking for unattended production. It also implemented quick-change Capto tooling from Sandvik Coromant at tool turret positions subject to frequent change to speed setup of new jobs at the end of the day shift. Certain other changes are proprietary, because staff members overcame some glitches in imaginative ways that they hope competing shops won’t figure out soon. The creativity of Hogge Precision Parts’ employees was among the enabling factors that made the move to unattended production possible.

事实上,这些员工是维特的承诺al. The staff itself had to change. Various senior employees date from when the company was a screw machine shop. Their mechanical experience came fully into play, because the imperfections that had to be addressed to bring the CNC machines into unattended production generally were mechanical problems. But at the same time, the mindset this staff brings to production had to shift to embrace going lights-out. Gone, now, is the expectation that human eyes or human hands will be involved with any job as it runs.

“The question for us is no longer, ‘Can I run this job unattended?’” Mr. Hogge says. “The question now is, ‘How long can this job run unattended?’”

NEW OPTIMAL STAFFING

Mr. Hogge remotely checks in on after-hours production via cameras mounted throughout the shop. “I am looking for green lights,” he says. Today, he almost always sees them.

That hasn’t always been the case. Even after it had begun to succeed with lights-out machining, the shop aimed for 65 hours per week of this production. Getting that much unattended machining was an achievement.

Today, he says it’s a disappointment to get less than 80 hours per week on most of the shop’s machines. Newer machines with control functions such as worn tool management can extend that to 100 hours. By comparison, the shop’s one fully staffed shift still accounts for no more than 45 hours per week.

Adding staff has become even more difficult in the time since the shop went to unattended production. Large manufacturing companies in the area have been adding staff themselves, bidding up compensation rates. This rural part of South Carolina has now become a high-wage region.

Even so, the shop has increased its payroll, including adding some employees who come in at night. Certain unattended processes reach capacity limits before the night is done, meaning attention at just the right moments can keep these processes running. On some jobs, for example, the Rota-Rack carousel is full after four hours. When an employee stops in to empty the unit, this brief intervention unlocks another four hours of production.

This kind of strategic use of labor increases the value of each staff member’s efforts. This is the measurable payback of the shop’s investment in achieving a reliable automated process. In fact, now at 45 employees, the shop may have found its new optimal staffing level. By servicing processes that run mostly unattended, Mr. Hogge says this number of employees can keep up with a sales volume that has now surpassed what the shop had achieved before the crash.

.jpg;width=70;height=70;mode=crop)