Five-Axis Machining Has Special Workholding Needs

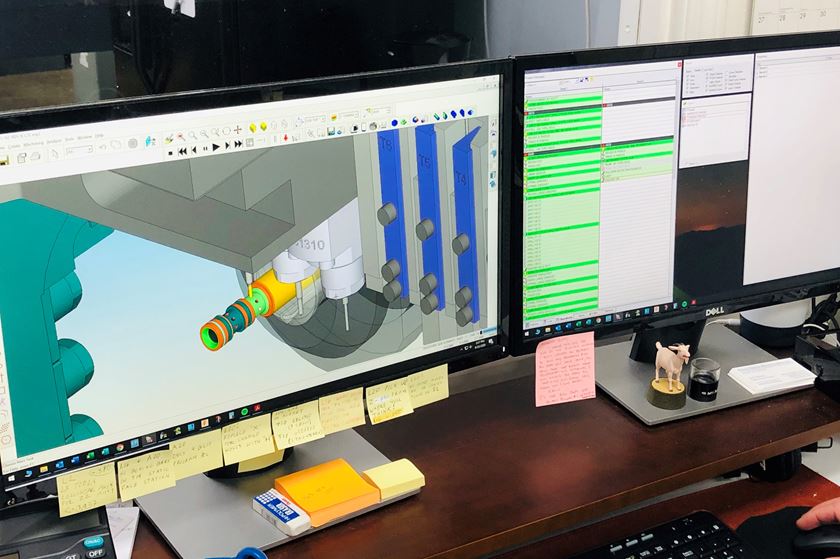

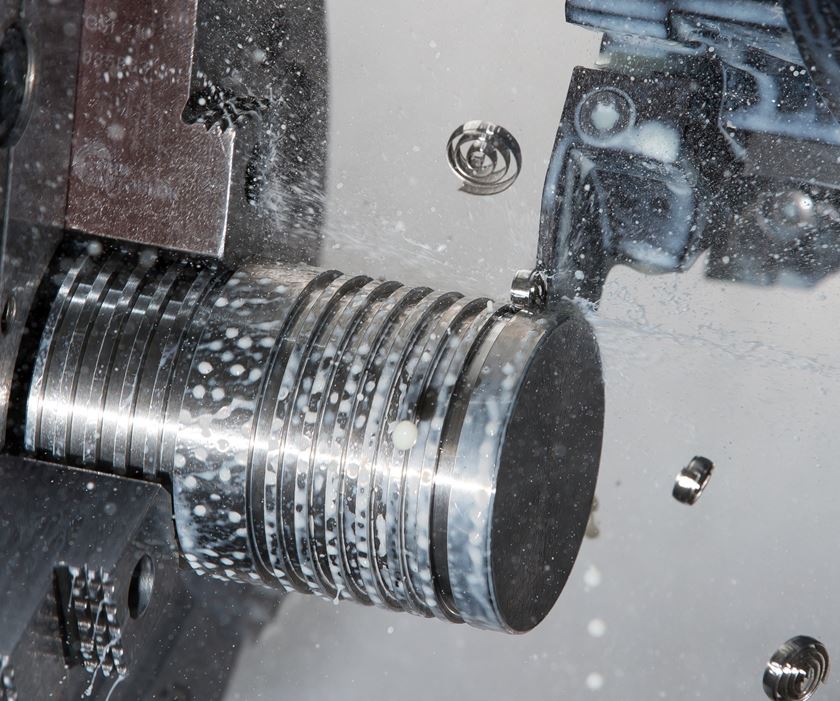

This clamping system allows a workpiece to be rigidly clamped while raised up from the surface of the worktable on a five-axis machining center. Moving the workpiece away from the table creates clearance for the spindle nose and cutting tool when the table swivels the workpiece for multi-sided machining, or when the spindle head rotates and swivels to do contouring or sculptured surfaces. Without this clearance, the user may be forced to refixture the part or to switch to a longer, less rigid tool.

Vise Clamping For Five-Axis Machining Video: An online video demonstrates how this clamping system helps keep the worktable out of the way of the spindle and cutting tool as they approach multiple sides of a workpiece.

A five-axis machine can be a tremendous resource, yet workholding limitations can diminish its value. Getting the spindle and cutting tool close to the work can be an issue when the worktable gets in the way, for example. A recently-introduced clamping system allows a workpiece to be rigidly clamped while raised up from the surface of the worktable. Moving the workpiece away from the table creates clearance for the spindle nose and cutting tool when the table swivels the workpiece for multi-sided machining, or when the spindle head rotates and swivels to create contours or sculptured surfaces. Without this clearance, the user may be forced to refixture the part or to switch to a longer, less rigid cutting tool.

Developed and manufactured by Schenker in Germany, the system is offered in North America by Kurt Manufacturing Co. (Minneapolis, Minnesota). The most significant design feature of the clamping system, designated the Kurt VB 5AX 100, is the location of the tension spindle, which is mounted directly below the supported workpiece. This means that clamping forces are applied near the top of the upright vise jaws as shown in the illustration. When clamping forces are applied away from the contact surfaces of the jaws and near the table, the jaws may flare out under tension. This deflection reduces the clamping forces and the rigidity of the setup. As a result, the user may have to cut back on feeds and speeds to avoid chatter. The new vise is designed to avoid these limitations and compromises.

Featured Content

另一个值得注意的设计特点是workpiece-support plate that is attached to the inward-facing side of each jaw. The two opposing plates provide a secure seating surface for the workpiece before the vise is tightened, thus contributing to the repeatability of the system. Optional workstops provide positive location and referencing if desired. The clamping surfaces are only 8 mm (0.315 inch) deep to minimize obstruction of the workpiece.

The mounting blocks under each jaw can be bolted in the standard T-slots or location grid of the table. They can also be attached to custom fixtures. The jaws, one stationary and one movable, fit on the mounting blocks to achieve a height above the table of 177 mm (6.889 inches). Optional risers can move the workpiece to 200 mm (7.874 inches) or 225 mm (8.858 inches) above the table.

The tension spindle reaches from jaw to jaw, with the appropriate extension shafts added as necessary. The smallest clamping width is 2 mm (0.079 inch). The longest extension shaft is 240 mm (9.448 inches), but shafts can be combined for greater clamping widths. The system supplies a clamping force of 40kN (8,992 lbs).

Combining sets of clamps makes it possible to clamp large workpieces. For example, two sets can be used to hold a rectangular workpiece by clamping it with a pair of jaws at each end. Round pins inserted in the top of the jaws provide secure clamping for circular or ring-shaped workpieces.

A five-axis machine can be a tremendous resource, but it can also be a tremendous investment. Investing in accessories such as

special clamping systems can help a shop get the most out of this resource.

RELATED CONTENT

Tooling Up for Micromachining

Choosing the right tools and matching them to the correct operations and process techniques for micromachining applications is critical to success in this burgeoning market.

Advances in Swiss-Type Technology

R&D efforts in recent years have led to higher efficiencies, increased agility and expanded capabilities for shops performing Swiss-type turning.

Straight From The Source

Seeing the cold drawing process up close can provide an entirely new appreciation of the barstock used in a shop. Here's how one mill makes the most of the process.