研磨后,磨练操作改善了最终的抛光操作之前的表面饰面。自动车轮测量过程有助于确保每个磨练操作都从正确的进纸位置开始。

Photo Credit: ANCA

Medical industry experts estimate that orthopedic hip surgeries will increase at a rate of 5% year-to-year until 2026. This is no surprise, given the growing aged population around the world. With this trend, an increased demand for devices and components to support these procedures as well as equipment to produce them will emerge. One example is theANCAmachining process for femoral ball grinding, developed jointly with grinding wheel manufacturer Tyrolit. This process is said to deliver quality and consistency in the finished femoral ball, using specialized machine control and technology on the ANCA MX7 Linear CNC grinding machine.

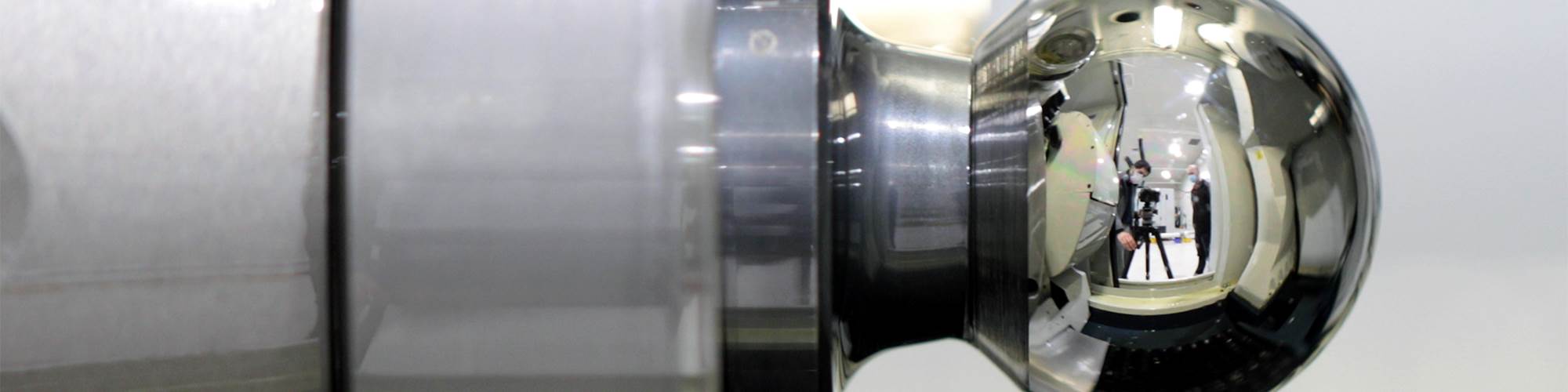

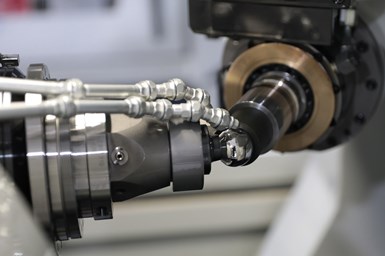

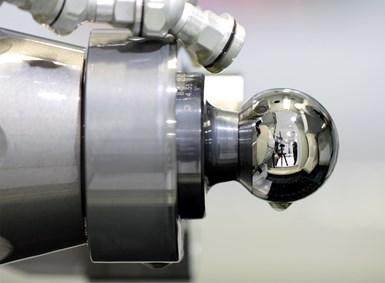

Effective performance of femoral balls used in hip replacement implants demands consistency of roundness, size and surface finish. To achieve this, ANCA has developed a process on its MX7 Linear machine that applies a series of sequential grinding, honing and final buffing operations in the same work envelope. The result is a surface finish on the ball of less than 0.01-micron Ra and part roundness of less than 3 microns.

Featured Content

该过程的第一步是将初始零件准确地磨成大小。使用镀层的CBN磨轮,从粗糙转弯的部分中除去了多余的材料。通过放松磨削过程中对零件的公差需求,这一操作更容易使上游过程更容易。

Next are a series of fine honing processes that produce incremental improvement in the surface finish. Application engineers from ANCA and Tyrolit combined to develop a process that delivers stable production results on the femoral ball.

成品球的表面饰面小于0.01微米RA。

尽管已专门为股骨球应用开发了塔罗氏轮,但在生产过程中自然发生磨损。根据ANCA的说法,它有能力应对这一挑战,因为它是其自己的Linx线性电动机的设计师和制造商,以及控制机器和打磨车轮运动的CNC和伺服驱动系统。ANCA系统工程师为该应用程序开发了一种新的控制算法,该算法使操作员能够对股骨球上施加的所需力进行编程。借助这种编程的力,车轮在磨损时以恒定的速率进对球。可以使用自己独特的磨削力参数来编程使用的三个不同的蒂罗利特车轮,以实现镜面表面饰面和一致的零件尺寸公差。

A final buffing operation delivers a mirror finish on the working surface of the femoral ball. Photo Credit: ANCA

此外,开发了自动车轮测量过程,以帮助确保每个磨练操作都从正确的进料位置开始。据说这可以在每次磨练操作后都能提供过程一致性。

Read: Preparing Tool Grinding Machines for IoT

A final buffing operation is the last step, creating a mirror finish on the working surface of the ball. This is critical for ensuring mechanical friction and wear are minimized in the final hip implant.

成品球的表面饰面小于0.01微米RA。Photo Credit: ANCA

成品球的表面饰面小于0.01微米RA。Photo Credit: ANCAANCA MX7线性具有六轮打包机的换挡器,使所有磨削,磨练和抛光操作都可以在一个设置中进行。此外,可以轻松更改用于股骨球生产的工具用于切割工具制造应用。结果,制造商可以将其机器用于其他CNC磨床应用程序,而不是购买用于股骨球生产的专用机器,以补充其市场和业务模型。例如,在同一台MX7线性机器上,都有可能在手术旋转切割机,钻头和铰刀以及股骨髋关节RASP上打磨。

相关内容

医疗加工在基因中

Sometimes it’s difficult to stay away. This company is an example of a precision machining family that simply can’t stop doing what it does.

Dry Swiss Machining in Medical

Continuing to build its reputation for creative solutions, this multi-faceted medical device component manufacturer took its Swiss machining operations to a new level to meet a customer’s market demands.

Rotary Broaching 101

There continues to be new ways of driving fasteners into the materials they are intended to hold together.