用调制钻井免费提供啄

A system for center drilling on Swiss-types and other small lathes oscillates the drill up to 1,000 times per second. Cycle time, part quality and predictability all improve.

This animation illustrates MAM.

Almost anyone who has ever drilled a hole knows the value of a peck drilling cycle. Periodically backing up the drill helps manage both chips and heat within a deep hole. In recent years, Purdue University researchers have worked to develop a technology based on a straightforward idea: If pecking every few seconds during the drilling cycle is good, then pecking hundreds of times per second might be dramatically better still.

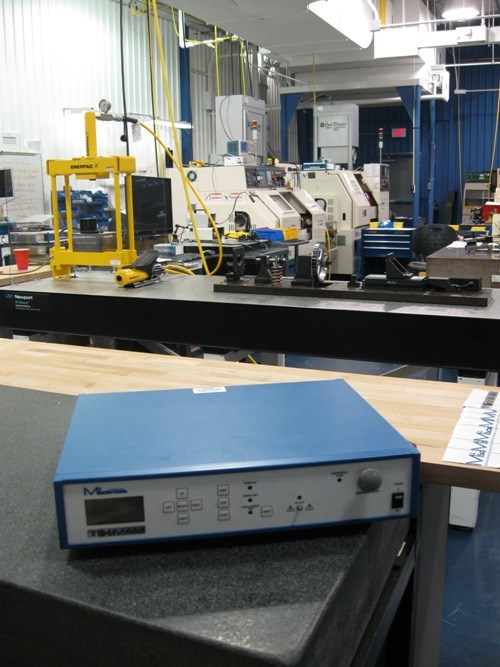

Modulation Assisted Machining (MAM) is the commercial name for this now-patented technology—sold by a company incubated by the university, M4 Sciences of West Lafayette, Indiana. Thanks in part to funding from the National Science Foundation and Indiana’s 21st Century Fund, M4 Sciences was able to take an idea that had been proven in laboratory settings and translate it into a self-contained product that can be installed and applied on production CNC lathes.

Featured Content

到目前为止,车床是这项技术的唯一目标,它们严格适用于中心钻井应用。该公司的“TribeMAM”调制单位在车削机的工作区中的负载,如刀架,并连接到一个小型独立的控制器。该系统最适合紧凑的数控机床,特别适用于紧凑型数控机床,适用于紧凑型车床。对于这些机器,该技术提供了巨大的生产钻井的潜力 - 特别是在钛和其他硬质金属中。

使用妈妈,啄钻循环是免费的。Tribomam单元在切割时振荡钻孔,使佩划持续。M4科学总裁Jeff Bougher表示,这会延迟编程的Peck周期,同时也允许更具侵略性的饲料。通常,公司承诺钻井周期时间至少为50%。

细微控制的啄物在频率下发生至每秒1000次。基于由操作员输入的钻孔参数(速度,进给速率,钻头和钻头数量),实际频率和幅度都是由系统的控制器决定的。除了周期时间改进之外,Bougher先生表示,振荡的好处包括以下内容:

•更好的润滑。他说,连续振荡为润滑剂留下润滑剂的空间。保持润滑剂在切削刃处,使通过工具冷却剂更有效。

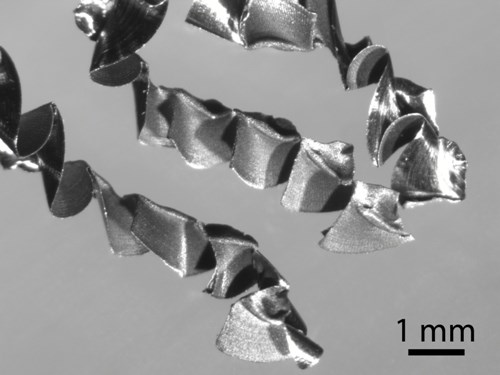

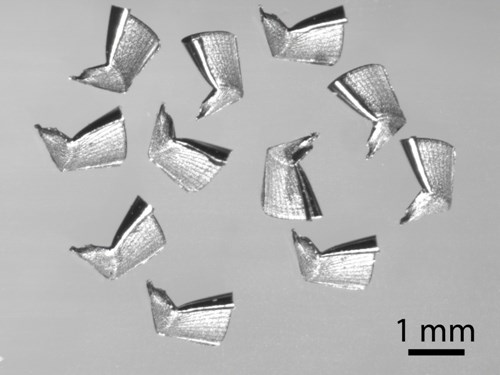

•更好的芯片疏散。Chips are small thanks to the rapid pecks. This ultimately produces more consistently accurate holes because chips no longer get bound up with the tool to distort the hole’s shape.

•Consistently shaped chips, which lead to a more consistent drilling process overall.

This final benefit might well be the most valuable, Mr. Bougher says. Manufacturers of high-value parts, such as aircraft fuel system components and orthopedic screws, increasingly do not find their efficiency gains solely by running faster. The savings also come from engineering a process that runs with less human oversight. Doing this requires machining operations that perform predictably—cut after cut and hour after hour.

MAM’s ability to control the chip contributes to this predictability, he says. What’s more, users get this consistency and predictability essentially for free, because there is no need to reduce cycle time to make the cutting more consistent.

相关内容

Thread Milling Tips for Tricky Aerospace Materials

Compared to tapping, thread milling offers advantages for creating threads in challenging materials such as high-temperature alloys.

直接从源头

Seeing the cold drawing process up close can provide an entirely new appreciation of the barstock used in a shop. Here's how one mill makes the most of the process.

Cutting a Micron at a Time

当任务要删除非常少量的材料时,这个过程可能是答案。

.jpg;width=70;height=70;mode=crop)