Cycle Time Is In The Cut Now

High volume machining centers have become so efficient outside the cut that the widest margin for productivity gain is within it.

At 26 tool changes per 6-minute cycle, most of the action on IPT's machining centers takes place outside the cut. For example, a representative drilling sequence involves tool change, broken tool detection, rapid traverse, and pallet rotation to orient the workpiece for the new cut. Machining moves—actually making chips—constitute only a fraction of the steps in the NC machining process.

But chart cycle time, and the picture changes. IPT's machining centers perform the various out-of-cut functions so efficiently that together these steps account for less than half of total cycle time. All of the rest is machining—even though IPT cuts near its top spindle speeds.

Featured Content

Machining time therefore offers the widest margin for future cycle time reductions. Speed in the cut is one of the factors that allowed IPT to choose machining centers over transfer lines. Now, the best opportunity for significant productivity gain lies in even faster cutting—the convergence of machine, fixture, and tool technologies to let the process economically and reliably exceed its current speed limits. This is IPT's case for high speed machining.

The Application

"IPT" is Indiana Precision Technology, a supplier of fuel injection systems for Honda. The company integrates casting, machining, and assembly under one 360,000-square-foot roof in Greenfield, Indiana. Last year, IPT manufactured fuel injection systems for just under 700,000 Honda cars.

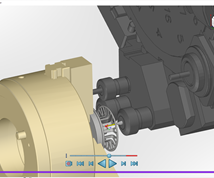

Makino A55 horizontal machining centers machine mating and mounting features for the largest component of the system, the cast aluminum intake manifold. Twelve A55s run near-continuously to mill, drill, and tap four-cylinder manifolds at the rate of 1500 per day. Eight more A55s ramp up to what will be a comparable output of V6 manifolds and injector bases.

Drilling is performed at 12,000 rpm, the top speed of IPT's oldest A55s. Machines purchased more recently could go faster, but then NC programs would no longer be interchangeable from machine to machine. Milling is performed at 8,000 rpm spindle speed and at a 260-ipm feed rate, to an average depth of 0.080 inch, typically using a six-tooth face mill 4.3 inches in diameter.

IPT staff engineer Thomas Mann led the development of the manifold machining process. He says total productivity—both in the cut and out—made machining centers a viable contender for what would historically have been a transfer line part. Flexibility is the reason why machining centers won.

Manifold Options

"The decision came from what we call a possible-problem analysis," Mr. Mann says. "We asked: `What would happen if a transfer line went down?'"

There are two configurations of the four-cylinder manifold—sideflow and downflow. This means that two transfer lines would have been needed. Lose one line, and the plant would lose its capability to produce the affected configuration.

Not so with machining centers. Lose even a comparable level of machining center capacity, and the plant could still divide production of both configurations among the remaining machines. Says Mr. Mann, "You just copy programs and carry fixtures to the machines that are left."

The 6-minute, 26-tool change cycle is actually the second of two manifold machining operations. A prequalifying "Op 1" first performs either 8 or 15 percent of the total machining, depending on the configuration. "Op 2" takes care of the rest. Both operations machine features at multiple angles through in-cycle pallet rotation.

On an uneventful day, each machine is effectively dedicated by operation and configuration. It's the eventful day that makes flexibility important. When demand for a given manifold model suddenly increases, or capacity drops because a machine needs maintenance, the freedom to run any manifold on any machine gives IPT a much broader range of options for responding to the change.

有时,IPT知道改变即将到来。每个four to five years, the manifold parts see major redesigns. Indeed, Mr. Mann says the current manifolds are radically different from those the A55s were originally purchased to produce.

Machining centers simplify these engineering changes. New cutting tools, and possibly a new fixture, are the only hardware required for the transition. The rest is programming.

An aside: Flexibility doesn't always win out over transfer line productivity at IPT; the company still uses and considers dedicated systems. For example, IPT will soon produce a new model of injector base, a part for which Honda has said there will be no significant design chang-es for at least eight years. For Mr. Mann, eight years—versus the manifolds' four or five—was enough to change the math. Machining centers were no longer attractive. He chose a rotary transfer system.

Loss Reduction

Unlike a transfer line, a machining center has to reconfigure itself to machine each new feature—for example, by feeding to a new position and/or changing tools. These losses should hamper IPT's complex process—particularly Op 2, which has the machine retreat from the workpiece for a tool change roughly once every 14 seconds. However, IPT's application illustrates how horizontal machining centers have evolved to minimize one after another of the out-of-cut contributors to cycle time, leaving even faster machining as the best chance to increase productivity further.

One of the most basic productivity enablers is the two-pallet design. IPT does have a part it machines on a vertical machining center, and part loading and unloading has to be figured into the cycle time. By contrast, the operator loads and unloads a horizontal machining center pallet while the other pallet is in the cut. This leaves pallet transfer as the only delay between cycles.

IPT feeds all of its A55 machines manually, except for five that are served by a shared pallet shuttle. Operators load parts into pre-gaged hydraulic fixtures on the stand-alone machines. Each operator typically serves three A55s.

Fast tool change is also paramount to IPT's process, but the A55 machines provide more speed than necessary. The latest of these machines are capable of 0.9-second tool change, but Mr. Mann wonders, "How many times will they do that?" IPT's process requires each machine to perform thousands of tool changes per day. For the sake of caution—and maintenance—Mr. Mann runs the toolchangers below this top speed with little compromise to cycle time.

Rapid traverse once did limit productivity, but no longer. Feed rate acceleration was lower on earlier A55 models. IPT's first such machines tended to slow down through right-angle moves, because of the need to stop and start in the corner. Mr. Mann solved this program with a software macro that turns box-shaped moves—like pulling a drill from one hole and moving it to the next—into semi-circles. The change cuts almost 30 seconds from the cycle on the original machines. However, it has little effect on A55s purchased later. The newest machine model—called A55 Delta—has a much higher acceleration. The difference on this machine between a cycle with right-angle moves and one with semi-circles is negligible—only about 2 seconds across all such moves in the cycle.

Cycle Time's Refuge

Given the speed of all of these out-of-cut functions, Thomas Mann says, "Any major reduction in cycle time will have to come out of the cut." Even though the tool is away from the part for most of the steps in the process, the machining moves command the majority of cycle time. High speed machining—even higher speeds than IPT's current process—offers the best opportunity for significant cycle time gains.

RELATED CONTENT

Custom Tooling, Workholding Help Whip Rotors Into Shape

Whipple Superchargers uses unique form tools and dead-length-collet workholding for its B-axis turn-mill enabling it to create more accurate rotors for its brand of engine power-adders.

For Plateau Honing, Consider Ball Style

The ball-style hone is a specialized abrasive tool that is instantly recognizable by its unique appearance. For engineers in the automotive, aerospace, manufacturing and machining industries, this application-engineered hone, characterized by the small, abrasive globules that are permanently mounted to flexible filaments, is a flexible, low-cost tool for sophisticated surfacing, deburring and edge blending.

A 'HOLE' New Ballgame With Multi-Spindle Honing Systems

Automating the honing process is key to high-volume precision bore production with sub-micron accuracy.

.jpg;width=70;height=70;mode=crop)