集合提供质量一致性

质量一致性是商店成功的重要特征。为客户制作此类工作也需要商店内部的质量一致性,包括从商店管理到机器的工具和劳动力。

质量一致性是商店成功的重要特征。为客户制作此类工作也需要商店内部的质量一致性,包括从商店管理到机器的工具和劳动力。

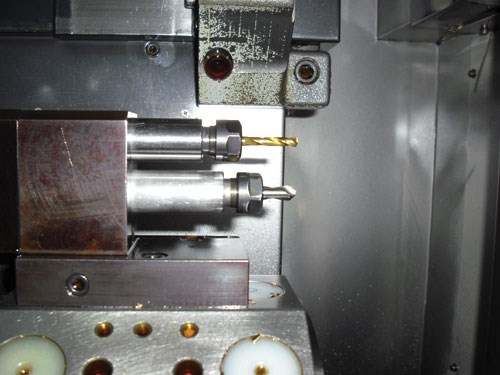

When you are a shop that produces tight tolerance, high accuracy custom parts, holding precision tolerances can be challenging. This is why Swiss Automation Inc. (Barrington, Ill.) recognized the importance of a quality collet when they began usingrego-fixcollets.

瑞士自动化公司发言人Vanessa Malo说:“您知道您每次都会得到什么。”“它们是可靠的,可预测的,并且没有问题。”

瑞士自动化出售给医疗,国防,航空航天,液压,电子和气动等行业。它通过拥有最新的和技术先进的设备以及使用和保留经验丰富的,知识渊博的创意人士,他们是好听的人和老师来蓬勃发展。

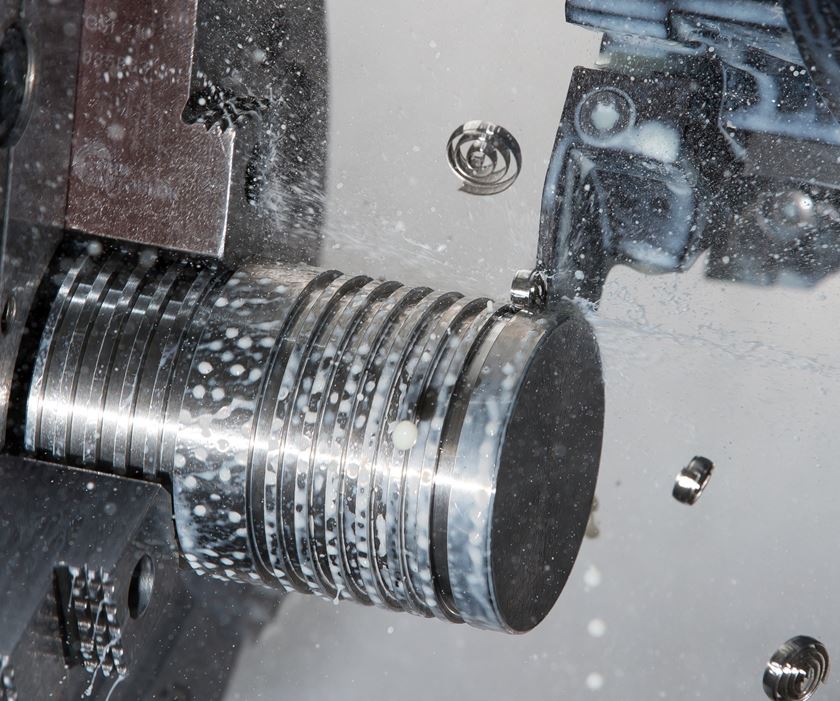

Producing accurate parts, which goes hand-in-hand with quality consistency, is beneficial to the company as well, especially when performing an operation such as micro-drilling. According to the company, these collets help achieve consistent accuracy for this tricky operation.

产品可用性是公司的另一个问题。必须快速交付和轻松访问分销商。马洛女士解释说:“即使一家工具公司没有我们正在寻找的rego-fix collet,另一个分销商也会拥有它。”“我们永远不必等待产品,也不需要

来代替。”

In the past, the company used Rego-Fix sealing disk collets. But when metallic sealed collets made their debut in the market in 2007, Swiss Automation made the switch. Deciding which type of collet to use comes down to a company’s personal preference, and Swiss Automation prefers the metallic sealed collets. "We’ve been using them ever since Rego-Fix came out with them, and they have made a big improvement for us," says shop foreman, Marc Moran.

在使用了密封磁盘夹和Rego-Fix的金属密封夹后,该公司发现了两种类型的夹具的质量一致性。莫兰先生解释说:“这两个夹子系统都可以很好地工作,但是当需要更换夹头时,高压(金属密封)夹的开关非常容易,因为它都是一部分。有了密封的磁盘,可以通过冷却液压力消灭。”由于夹头更换是如此简单,因此它也节省了操作员的时间。

Ms. Malo adds, "They (the metallic sealed collets) are a good alternative to the sealing disks, as the sealing disks require more maintenance and parts."

“在金属密封件之前很早就出现的密封盘系统上,我们有一个特殊的螺母和密封盘,可以将其插入螺母中,将冷却液锁定在螺母中,” Rego-Fix产品经理David McHenry解释说。“有了这个系统,您就有一个螺母,然后有一个磁盘,因此您必须跟踪两个部分。”必须为每个尺寸购买特殊的螺母和磁盘。

然而,使用金属密封系统,填充物全是一件。麦克亨利说:“夹头本身将冷却液密封,并完成所有工作,甚至使冷却液通过切割工具进行。”失败是,当使用此系统时,您没有完整的填充范围。其他夹子的夹具范围约为1毫米,但是使用该系统,没有夹紧范围或仅0.5毫米范围。他补充说:“您最终需要更多的夹具来覆盖夹紧范围。”

尽管密封磁盘系统的缺点是它包含更多的零件,因此,其优势包括可以使用标准夹子(不需要特殊夹具)的事实,并且提供更宽的夹紧范围。

According to Mr. McHenry, the sealing disks also offer a higher cleanliness factor. By design, the seals are in front of the collet, which keeps the collet itself cleaner in the case of machining hard materials that produce very small chips such as brass and graphite, he explains. "The open slots in the collet are exposed and the chips may pack in those slots and call for more cleanup between tool changes," Mr. McHenry says. However, if you are cutting aluminum and steel, this isn’t a problem, he adds.

然而,根据莫兰先生的说法,瑞士自动化机器许多不同类型的金属,包括硬材料,并且芯片清理没有问题。他解释说:“我们不必清洁夹子,因为冷却液通过使其清洁。”

瑞士自动化依赖于重型固定夹,具有紧密的公差,这反过来又产生了质量一致性和高精度。

RELATED CONTENT

在车床上伸出

Producing a keyway, spline or similar longitudinal feature on a turned part usually necessitates an additional, time-consuming, secondary operation on a broaching or slotting machine. That means moving the part to and from a secondary operation, an extra setup, additional labor and hourly machine costs and all of the other headaches that go with secondary operations.

Making Micro Threads

Production of micro threads can be challenging, but using the most suitable tools for a given application can simplify the task.

Precision Lathe Operations on a CNC Mill

Sometimes a shop doesn’t do enough turning work to justify the purchase of a CNC lathe. But when it needs to produce precision turned parts, even if for a very small lot size, the shop needs a solution.