Ceramic Inserts Can Boost Turning Productivity

When applied correctly, ceramic inserts can dramatically increase cutting speeds, providing shorter cycle times and cost savings compared to carbide for turning operations.

Carbide inserts are the most commonly used solution for many turning applications because they offer good performance at a reasonable price. However, ceramic inserts are worth considering as an alternative in some turning applications.

Ceramic is an advanced cutting material that, relative to carbide, is harder and enables machining at higher cutting speeds, but is suitable for only specific applications and workpiece materials.

Featured Content

Although ceramic inserts cost about two to three times more per cutting edge when compared to carbide inserts, the benefits are substantial in some applications and provide cost savings by reducing cycle times.

Advantages and Types

Made from aluminum oxide (Al2O3) or silicon nitride (Si3N4), ceramic inserts provide an advantage over regular carbide inserts. While a typical carbide grade has a hardness of 1,300-1,800 HV, ceramic grades have a hardness of about 2,100-2,500 HV (about 40% harder). Ceramic also has chemical stability in high temperatures as well as low temperatures. And with low thermal conductivity, most of the heat is transferred to the chip, not to the cutting tool.

陶瓷插入物分为几个子类型。这些类型的颜色不同,组成和证明在不同的应用中更有用。此图表说明了每种类型:

Acceptable Applications

Ceramics provide excellent performance when machining hardened steel, cast iron and nickel-based alloys.

Hardened steel.With coated carbide inserts, it is possible to machine steel up to a hardness of about 45 HRC if a low cutting speed of no more than 300 SFM is maintained. With ceramics, however, the cutting speed and machine material can be doubled, up to a material hardness of 60 HRC.

使用CBN插入物是转动硬化钢的另一种常见解决方案。CBN的运行速度比陶瓷插入物和机器钢的运行速度更快,高达70 hrc。但是它们比陶瓷插入物高四倍。陶瓷插入物在45至55 HRC范围内转动硬化钢的价格和性能之间提供了平衡。

用碳化物切割速度 |

160 - 320 SFM (Up to 45 HRC) |

陶瓷的切割速度 |

330 - 660 SFM (Up to 60 HRC) |

生产力增长 |

+100% |

推荐的陶瓷类型 |

黑色和混合 |

Cast iron.铸铁零件主要是在循环时间至关重要的大量生产中发现的。陶瓷可以在2600平方米处运行,同时切割铸铁,并且可以将周期时间降低40-60%

用碳化物切割速度 |

600-1,000平方英尺 |

陶瓷的切割速度 |

1,300-2,600平方英尺 |

生产力增长 |

+150% |

推荐的陶瓷类型 |

氮化硅,白色和黑色 |

基于镍的超级合金。Many nickel-based parts are used in jet engine components. Some of these components are large and can reach a diameter of 20 to 40 inches. The combination of the size with the slow speeds (around 150 SFM) yields long cycle times. It is not uncommon that a single part is machined over several days. Therefore, the fact that ceramic inserts can run up to six times faster makes them a popular solution in this industry.

用碳化物切割速度 |

60 - 200 SFM |

陶瓷的切割速度 |

500-1,300平方英尺 |

生产力增长 |

+500% |

推荐的陶瓷类型 |

Sialon |

加工技巧

The extra hardness of the ceramic material, however, results in extreme brittleness characteristics. Therefore, if proper guidelines are not followed, ceramic inserts can break. On the other hand, when mastering the proper techniques, machine shops can achieve a dramatic reduction in cycle time and maintain a safe process. Edge preparation, overall stability and chamfers at entry points are three key factors to consider when machining with ceramic inserts.

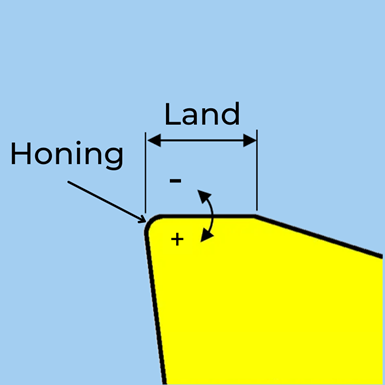

边缘准备。Edge preparation is the term referring to the micro-geometry of the cutting edge. This tiny area stretching between 0.0005 inch to 0.008 inch has an important effect on the performance of cutting tools. In ceramic cutting materials (and CBN) it becomes a critical factor.

When turning with ceramic inserts, it is important to match the edge preparation per a specific application. Therefore, a reputable supplier of ceramic inserts will have several edge preparations for each geometry in its catalog.

边缘制备由三个参数组成:土地角(零或负),土地宽度和磨练尺寸。每个参数越大,切削边缘变为越强。当应用程序涉及重中断的切割时,应使用具有负角度的宽K陆地。为了平稳,连续切割,磨练可能就足够了。

Overall stability.在使用陶瓷插入物转动时,稳定性至关重要。应采取每项措施来增加它,其中包括牢固的工具夹紧,悬垂短和良好的工件支持。

Chamfers at entry points.应使用碳化物插件在工件末端准备倒角。然后,应使用陶瓷插入物输入切口。在尖锐的角落进入工件可能会破坏陶瓷插入物。

Eric Spencer is the founder ofMachingDoctor.com, an online machining technical hub.

相关内容

The Many Sides of Workholding

这是对劳动力的不同方式的广泛研究,从饲养者到鸡舍,再到机器人技术。

酒吧给料机基础

Some primary factors are often overlooked when considering how to justify the implementation of a bar feeder for turning operations.

当线程铣削很有意义时

螺纹工件是每个制造工程师理所当然的基本金属加工过程。