Automation Brings Reliability to Laser Marking Bone Screws

To overcome human error in laser marking, consider a reliable, high-throughput automated system designed to run 24/7.

#techbrief

Automation is popping up everywhere on machine shop floors, even serving manufacturing processes one might not expect. Laser marking machines, for instance, can be automated, which offers many benefits, especially for the medical industry.

美国食品药品监督管理局的监管 - 唯一的设备识别规则 - 指出医疗设备制造商对其产品进行标签的具体要求。因此,骨螺钉必须具有与其制造商相关的信息以及人类可读内容中的零件身份。此信息可确保正确的部分不仅在手术期间,而且用于可追溯性和召回(如有必要)。

Featured Content

Therefore,Foba Laser是激光标记和雕刻设备的制造商,已开发了专门为这项工作的机器。根据公司的说法,手动激光标记可能具有挑战性,尤其是在诸如骨螺钉之类的小零件上,在该骨螺钉中,小至300至500微米的激光标记对于适合螺丝头是必需的。手动激光标记或操作员处理的材料处理可能会产生错误的,扭曲或缺失的标记内容。

FOBA说,要获得更可靠和准确的激光标记放置以及更快的吞吐量,医疗部件制造商发现自动化此过程会产生最成功的结果,尤其是在处理大约1,000的批次时。通过最大程度地减少操作员的交互并整合自动化,可以在骨螺钉上的激光标记的精确定位和对齐。

一个例子是可自定义的自动激光标记机FOBA专门为骨螺钉开发的。FOBA LASER全球战略客户经理Faycal Benayad-Cherif说,不仅可以进行系统激光标记,而且还旨在验证零件,重新调整和检查激光标记。

Validating, Marking, Inspecting

骨螺钉的自动激光标记系统设计用于大量的24/7,用于轻型操作员。由于医疗行业依赖于骨头螺钉头上精确放置和清晰的零件识别编号,因此该系统的开发是为了产生高度精确的激光标记。

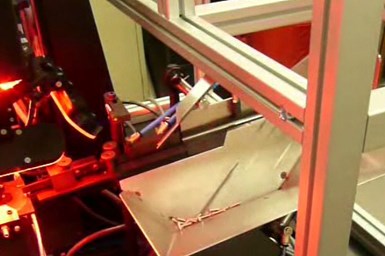

To start the bone screw laser marking process, an operator manually drops a lot size of screws into the bowl feeder (on the bottom right side of this image). The screws are then pushed by a knife in the machine into the channel to be validated, marked and inspected. Photo Credits: Foba Laser

The process begins with a manual operation, as an operator drops screws by hand, one lot a time, into the machine’s bowl feeder.

但是,骨螺钉将一一滑入馈线中,并将其推入移动通道。在通道中,将螺钉显示在激光器上以进行标记:每个螺钉都通过振动和重力的组合从水平位置重新定位到垂直位置,然后通过旋转的通道移动,使每个螺钉头朝向向上。

To ensure that the correct screws are marked with the correct information, before marking, the system’s camera looks for screws that match the correct diameter and features according to the machine’s software program. It validates the screw family type and rejects the screws that do not belong with the group by ejecting them into the “fail” bin within the system.

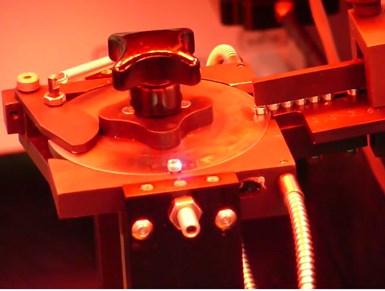

As the screws are moved through the system, they are laser marked by technology that automatically aligns the laser to the screw head, producing accurate and legible laser markings in the form of numbers.

This bone screw head (to the front of the photo) is being laser marked in the rotating channel within the machine. The FDA requires manufacturers to add traceability content on almost all medical devices.

标记后,自动化系统立即完成了光学特征验证,该验证检查螺钉以确保正确标记。机器的相机查找内容并验证螺钉头上标记的每个数字激光器,以确保准确的对齐方式并检查对比度以确保其清晰度清晰。如果螺钉通过检查,则机器将其放入“通行证”垃圾箱中;如果它不符合标准,则将其掉入“失败”垃圾箱中。

系统设置

Developed for easy use, this automated laser marking system has a push-button start, contains no fixtures and offers a small footprint of 1 meter by 1 meter. According to Benayad-Cherif, the goal of creating this machine was to provide an automated system that requires limited maintenance and involves minimum operator training and interaction.

Foba Laser’s custom automated laser marking machine for bone screws is compact, easy to use and set up, and designed for lot sizes as large as 1,000.

This system is designed to process a family of parts and includes functionality for a family length or diameter of screws. “You wouldn’t go from say a 3-millimeter to a 10-millimeter diameter screw, but you can go from a 3- to 5-millimeter diameter instead,” Benayad-Cherif explains. “So, the system has expected size limitations, but it is automated and that is the benefit.”

On some other, similar equipment where adjustments are required when changing over to a significantly larger part size, controls are kept simple and often do not require tools.

根据Benayad-Cherif的说法,运行设备也很容易。操作员在计算机的计算机上使用公司ID签名,然后将骨螺钉放入进纸器中。在计算机屏幕上,他/她使用条形码读取器进行大量扫描,该读取器激活了机器的激光标记过程。

相关内容

Setup Options for Swiss Automatic Lathes

A hydraulic chuck and a counter-balanced centering tool, originally developed as in-house solutions, are now available to address the limited working space that is common in Swiss machining.

智能劳动设备措施和监视

传感器和IIOT技术结合起来,使这些Chucks和Mandrels能够自动监测工人参数并测量零件特征以确保过程稳定性。

How to Collect and Use Machine Data

Manufacturers don’t need to limit the machine monitoring data they collect, but they do need to know how to collect the data and how to use it to drive decisions.

.jpg;width=70;height=70;mode=crop)