Automatic Pallet System Helps Pick Up The Pace

racecar驱动程序需要高性能组件来获胜比赛,但制造这些组件也需要速度。自动托盘更换器帮助本店不仅为其汽车客户提供生产,而且还为航空航天,医疗等行业的客户提供生产。

作为一个成功的赛车手,达里奥奥兰多understands that winning races depends largely on quality, high-performance auto components. And as the founder of a shop specializing in the manufacture of such parts, he also understands that the ability to turn around jobs quickly depends on the right equipment. On both sides of the equation—from the first cut to the point when the driver crosses under the checkered flag—speed is key.

On the manufacturing side, one way to speed things up is to automate production. That’s why Mr. Orlando’s shop, Steeda Engineering and Manufacturing, marked off the option for an automatic pallet system from Midaco (Elk Grove Village, Illinois) when it ordered a new VMC from Mazak (Florence, Kentucky). This acquisition increased output by more than 30 percent compared to the older machine it replaced, contributing to the shop’s ability to meet demand for its signature auto parts as well as components for the aerospace, defense, medical and other industries.

典型内容

Born to one of Ford Motor Company’s most influential designers, Mr. Orlando has always been an enthusiast of both engineering and high-performance automobiles. These twin passions led him to found Steeda in 1988. Since then, the company has become one of the largest producers of equipment for Ford vehicles, growing from two employees at a single shop to a 40-person team manning plants in Pompano Beach, Florida and Valdosta, Georgia.

管理层在公司历史上实现,即使具有最高的部分质量,速度努力加快生产和交付对竞争力至关重要。Aldo Flores,Foreeda的Valdosta设施表示,赛车以外的市场上增加工作使这一目标是持续改进更重要。“我们越来越多的新客户和行业需要更好,更快的技术,”他解释道。“更多零件必须在更短的时间内更有效地制作。”

有鉴于此,决心以避免d the problems it had experienced with existing equipment when seeking new machinery for the recently opened Valdosta facility. One particular area of need was a VMC that could provide better performance and reliability than what the shop could obtain from a model the company had used in its other location, a machine that Mr. Flores considers “entry-level.” After scouring the market for the right fit, the shop narrowed its choice to two different models. A visit to Mazak’s Florence, Kentucky manufacturing facility impressed management, Mr. Flores says, so the shop settled on that builder’s 510C VMC. “We felt that we were going to get the customer service that we would need to get up and running quickly, or if we ever had a breakdown in the future,” he explains.

该商店现在使用该机器主要用于铝零件。Flores先生说,高刚度,热控制,通轴冷却剂和主轴速度为12,000rpm,使VMC适用于这些应用中的粗加工和整理操作。他补充说,选择包括自动工具预防器是一个很好的投资,因为它确保操作员准确地触发刀具。

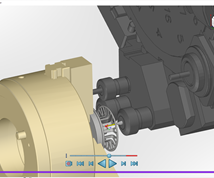

然而,VMC附带的另一种选择有助于消除上述前一台机器的更大困难。也就是说,在尝试从旧机器内置托盘换档器中拆下托盘时,运营商的运营商经历过。弗洛雷斯先生说,这主要是一个接入问题,它经常显着减慢运营。该商店需要更好的系统,并且在其卧式机上的多托盘系统已经使运营商能够更有效地使用它们,因此它为其新的Mazak垂直寻求了相似的能力。Midaco的A4020SD 40×20英寸自动托盘系统不仅提供了所需的商店的增加的生产速度,还提供了易于使用和改进的运营商访问加载和卸载。

As opposed to the built-in pallet system on the other VMC, the Midaco model enables operators to quickly and easily swap pallets, Mr. Flores says. Mounted on the side of the machine tool, the system is designed to provide full access to the shuttle and to enable part loading from either side or above. Built-in safety interlocks ensure that pallet changes can proceed only if the “pallet ready” button is activated and the CNC M-code is fired. “We really like how simple the Midaco is to use,” he says. “We also like that it can be mounted on the left, right or even both sides of some CNC machines. There is no interference for the operator, and that really helps us change parts fast.”

当一个部件的托盘完成时,操作员可以卸下部件,用空白重新加载托盘,按下“托盘就绪”按钮,然后走开往往是下一个工作。同时,VMC继续在交替托盘上进行操作,显着超速生产。“这与我们的水平磨机是一个很大的优势。现在,我们通过我们的新摩塔克VMC和Midaco系统获得这种福利,因为这一价格的一小部分,“Flores先生说。

With storage capacity ranging to 8,000 pounds, the A4020SD features a servo drive assembly that extends into the machining center, tilts and engages with the pallet coupler to remove the pallet. The next pallet is delivered to the machine within seconds, and hardened and ground locating pins deliver ±0.0001 inch repeatability, the manufacturer says. A custom “dual air blast” system blows air through and across the contact pads for chip removal. The company adds that the system can retrofit to virtually any machining center and that operators can use the PLC to program pallet acceleration and deceleration according to the weight of the fixture.

Reduced cycle and setup time, improvements in machine output ranging to 33 percent, and reductions in related costs should more than make up for the investment, Mr. Flores concludes. “If things continue to go as they are now, our return on investment would be 18 months on this pallet changer. That will help justify the cost of the next Midaco.”

RELATED CONTENT

From Virtual To Reality

本文讲述了如何在网络上使用的商店使用的信息来解决其商店地板上的艰难的生产问题。

Scratching Surface Flaws With Automation

加工零件在CNC多主轴上完成,具有自动负载和卸载,可从而证明这款Tier-Wier Auto Mape Maker的尼克和无划痕零件的关键。

瑞士型技术进步

R&D efforts in recent years have led to higher efficiencies, increased agility and expanded capabilities for shops performing Swiss-type turning.