Published|

5 MINUTE READ

Aerospace Shop Reduces Setups With Boring Mill

A recent survey prompted Ace Clearwater Enterprises to acquire a boring mill and implement a new MRP system. In turn, it was able to bring processes in-house and accelerate cycle times while better serving its clientele.

Manufacturers embarking on a journey to fine-tune operations should heed this southern California shop’s advice: solicit customer feedback. Asking clients what’s going right and what could be going even better can be part of any shop’s strategy to identify areas for improvement—regardless of the size or specialty.

As this Torrance, California shop recently discovered, that feedback can be surprising and potentially lead to unexpected rewards.

A recent survey prompted Ace Clearwater Enterprises to acquire a boring mill and implement a new MRP system. In turn, it was able to bring processes in-house and accelerate cycle times while better serving its clientele, which includes Honeywell, General Electric, Boeing, Lockheed Martin, Textron, Cessna, Pratt Whitney and others.

With 200 employees, Ace operates three facilities within a 10 square mile radius in southern California. In its machine shop alone, the company has eight vertical mills, one horizontal machining center, a CNC dual-column machining center, six CNC lathes and two waterjets. It has been servicing the aerospace and power generation industries since 1949. In the beginning, the company worked on welding contracts for aerospace companies. After earning accolades for its welding capabilities, the job shop broadened its services to include engineering, forming, tube bending, machining, waterjet cutting and assembly for materials such as titanium, Inconels, aluminum and stainless steel.

Since the early 1980’s owner and company president Kellie Johnson has been running the shop that her grandfather founded in 1947. Gary Johnson, Kellie’s husband and company vice president, joined the shop in 1992.

In an effort to identify ways to improve service and better meet the needs of its customer, Mr. Johnson conducted a comprehensive survey. The survey results indicated that although customers were generally happy with the quality of the products, they were less than satisfied with the actual delivery. In response, Ace devised a plan, the culmination of which would enable the shop to shorten delivery times and possibly expand its capabilities altogether.

“The logical next step for us was to clarify the problems and decide on the best approach,” Mr. Johnson explains. “We needed to know where jobs were in the shop and where the bottlenecks were.”

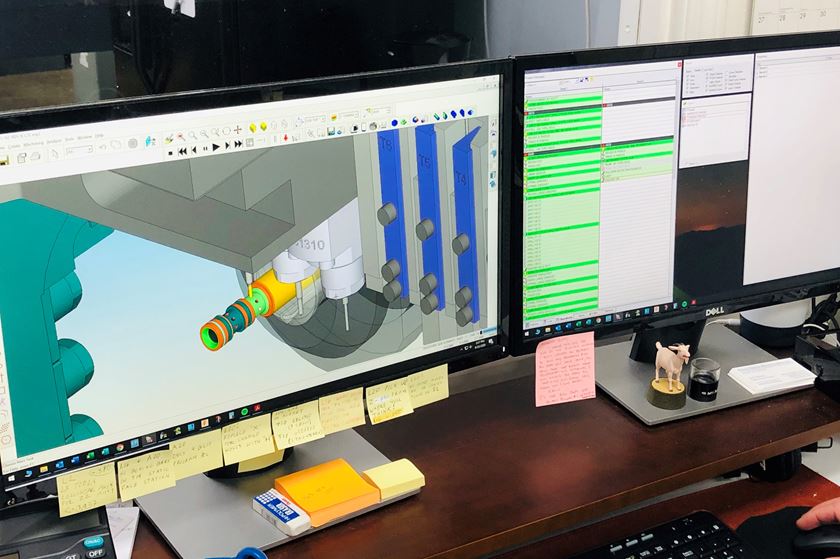

With the help of King Lum, who has been the company’s director of progress for the past 12 years, the company decided to implement a new MRP to enhance the visibility of costs and find ways to bring processes in-house.

“We wanted to track everything: purchasing, bar coding… you name it,” Mr. Johnson explains. “These needs led us to acquire a system called Symix. It tied everything in—time cards, shipping, receiving, estimating and accounting.”

Once Mr. Lum’s digitized environment was in full swing, then anyone could view a print simply by going to a terminal to call up drawings.

Since this system overhaul took place, Mr. Johnson reports that the company can have as many as 40,000 parts in production on its floor. But Ace wasn’t done yet.

The company’s second step was to check all of its equipment for opportunities to fine-tune the manufacturing sequence. Ace then discovered that all of its equipment was not capable of machining large weldments. Its horizontal machining center was too small. Consequently, parts had to be placed onto several machining fixtures to be completed. Multiple fixturing was also required to machine parts on the shop’s vertical machining centers.

“Some of our dies can weigh as much as 15, 18 or even 20,000 pounds,” Mr. Johnson says. “The biggest one we’ve machined has been 44,000 pounds.”

Because the company’s machines could not accommodate the weighty dies, Ace had to farm out a lot of the CNC machining. This arrangement seemed to aggravate the already sensitive delivery problems as business began picking up again, as well.

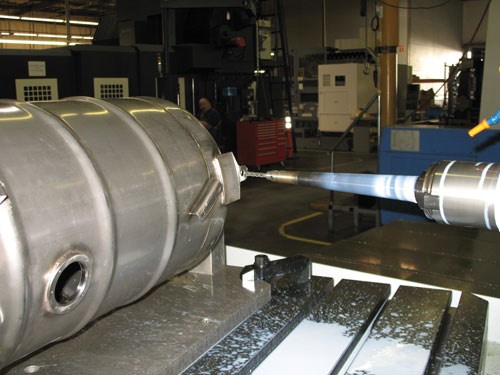

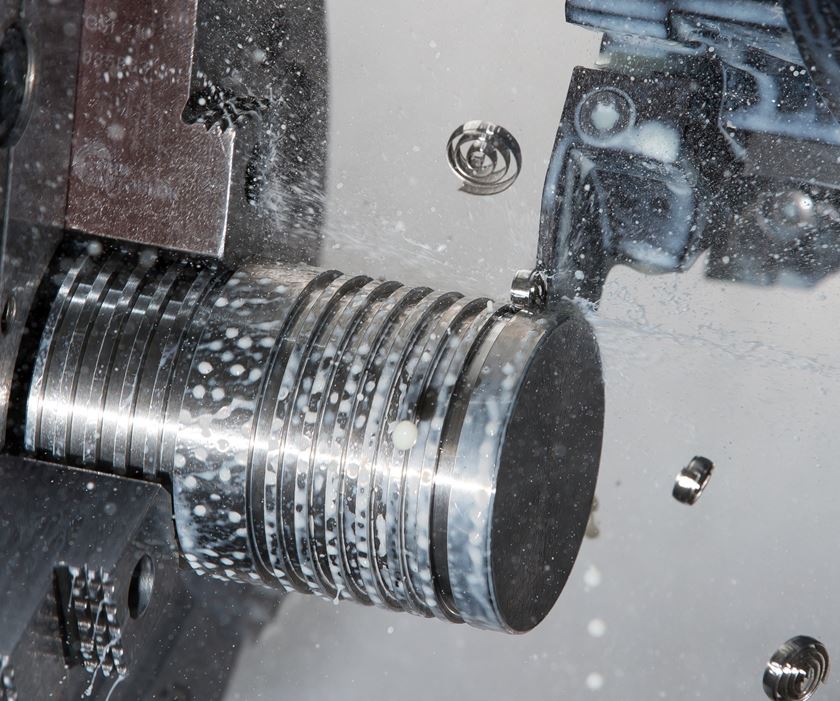

At that point, the company decided that acquiring some big equipment would be its best bet for bringing the machining of these big jobs in-house. It purchased four new machines, one being a Femco BMC-110 R2 boring mill. This particular machine includes simultaneous, four-axis control and a Fanuc 18MC controller. Constructed from a cast iron frame, the boring mill features hardened and ground box ways. The R2 model provides twice the Y-axis headstock travel and about 50 percent more X-axis travel on the table cross and longitudinal Z-axis travel than the manufacturer’s previous model. Travels are 78.74 inches table cross, 70.87 inches headstock and 66.93 inches longitudinal on the XYZ axes respectively.

The machine is large enough and open enough to handle everything that the company produces today. With its long-reach quill and rotary table, the company can now complete multiple machining tasks on large parts in one setup. Parts can be placed in one universal fixture without compromising access to all of the different compound angles that are to be machined.

“This expanded capability has made our operations more productive,” reports Dick Larry, manufacturing engineer manager. “The part never has to be moved, so there is less handling involved. Therefore, quality is never compromised. We’ve been able to cut cycle times by 50 percent. Previously, it might have taken us 4 hours to process a part. Now it takes about 2 hours or less.”

The boring mill is also used to prepare die bases for the other machines that make the forging dies for Ace’s welded components. There are numerous other functions that the boring mill is helping to support in the manufacturing process, the company says. The BMC-110 R2 is commonly employed to mill and drill large parts that it could not otherwise reach. Ace even reports using the machine to perform repairs on its older equipment.

As Mr. Larry explains, the company regards the new mill as an asset and tool to keep outsourcing at bay.

“目前我们正在加工存储容器stainless steel that we will be shipping to Brazil,” Mr. Larry says. “The boring mill has reduced 75 percent of the setup time associated with these parts while eliminating the time formerly required to outsource the machining.”

“We can now control our own destiny by keeping work in-house and processing our own engineering,” he concludes. “Using our own machines effectively keeps lead times short and costs down.”

相关内容

Tooling Up for Micromachining

Choosing the right tools and matching them to the correct operations and process techniques for micromachining applications is critical to success in this burgeoning market.

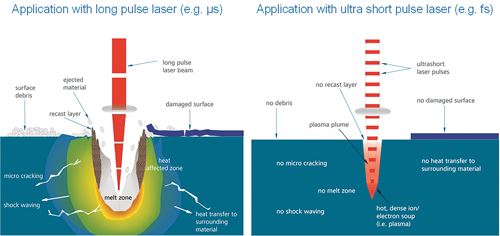

Cutting a Micron at a Time

When the task is to remove very small amounts of material, this process may be the answer.

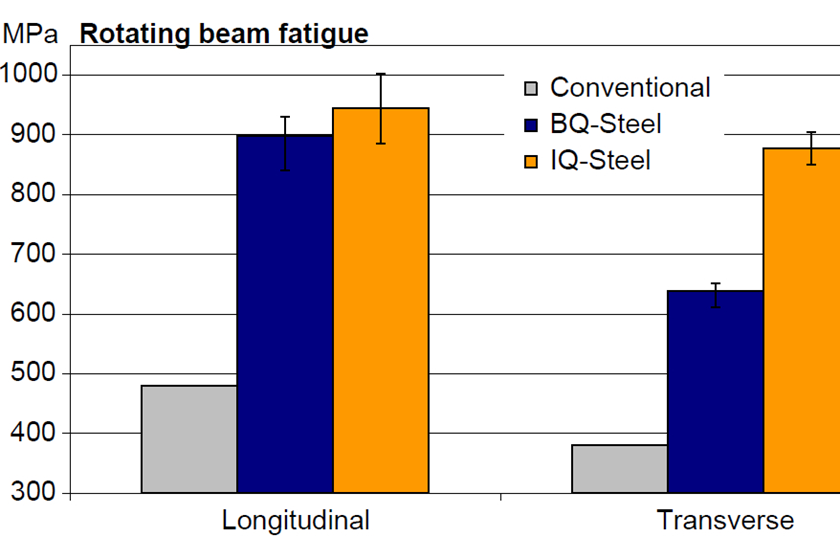

How Metallurgical Structure Affects the Machinability of Aluminum

Advancements in grain structure consistency and mechanical properties help to make this extremely machinable metal suitable for an ever growing range of applications.