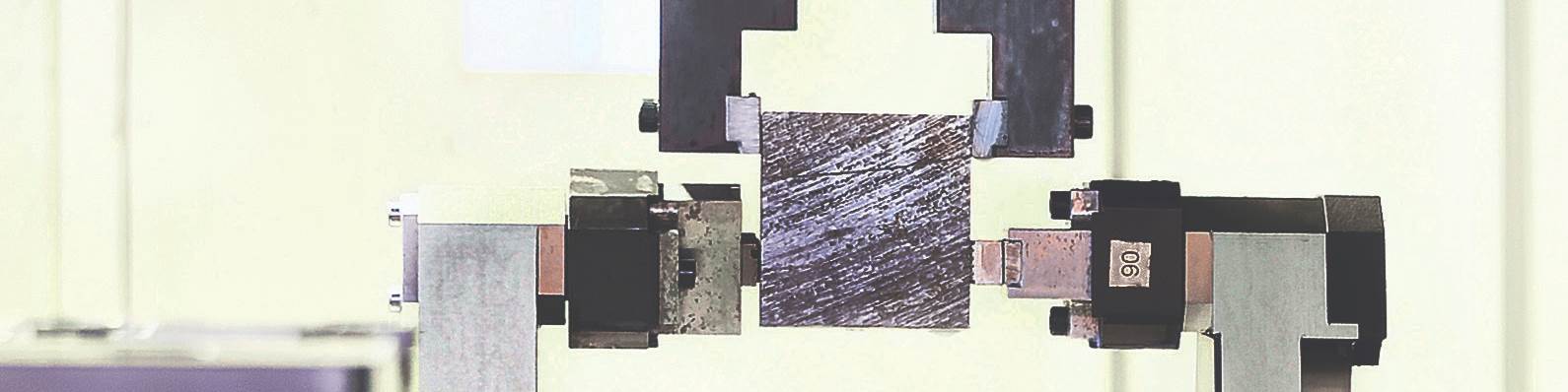

这种“精益自动化”解决方案使用机床元素,例如主轴旅行,刀具持有人,压缩空气或冷却液的供应,ATC和工件(而不是机器人)来自动化零件处理。图片来源:德意志Edelstahlwerke特色钢

Every day, test engineers at Krefeld, Germany-based Deutsche Edelstahlwerke Specialty Steel (DEW) determine the quality of the steel it produces by way of tensile and notched-bar impact tests. With a length of 55 mm and a square cross section of 10 by 10 mm, the standardized test specimens are rather unspectacular from a machining perspective. Yet their production requires one operator to manually load about 2,500 individual samples each month.

“It takes around 15 minutes to produce a set of three specimens on ourDoosanDNM 400 VMC建立了工作后。“在两个设置中进行两个设置,需要两个机加工操作(Op。10和Op。20)。尽管手动从OP手动重新缩短零件需要一分钟以上的时间。10次工作。20,操作员几乎没有时间不仅仅是一台机器。”

Featured Content

As a result, Richter investigated various possible automation solutions to increase flexibility and machine utilization. The goal was not to reduce staff but to open availability for employees to perform other more value-adding tasks. What’s interesting is that the solution the company chose didn’t involve a robot.

Letting the Machine Load Itself

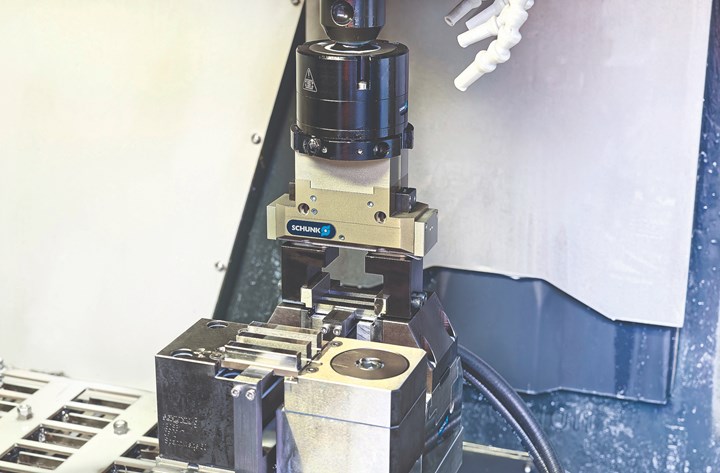

在最初想到拥有机器人的想法后,商店咨询了劳动设备制造商的代表Schunk,他建议其“精益自动化”解决方案。该解决方案旨在在没有机器人的情况下轻松,快速和成本地自动化机床。基本原则很简单:机器中已经存在的元素不是用于自动化零件处理的元素,而不是投资外围设备。其中包括主轴旅行,刀具持有器,压缩空气或冷却液的供应,自动刀具换挡器(ATC)和工件。

For loading, a Schunk universal gripper (that is clamped in the machine spindle using a conventional toolholder) moves to the workpiece magazine and removes a waterjet-cut blank to place it in a clamping block.

必要的额外的处理和清洗国防部ules are clamped into toolholders via a shank interface and placed in ATC pockets to be called up when necessary. Schunk’s Lean Automation grippers are actuated either with coolant or compressed air, which is supplied internally via the shaft interface with the connection module.

“我们喜欢加载的机器的想法inside as it was not only an economical way to automate it but safe and space-saving as well,” Richter says. “Everything happens inside the machine; shut the door and run,”

How it Works

用于OP的加载。10工作,带有GSW-B界面(使用传统刀具持有人夹在机器主轴上的链球)的弹圈抓手)移至工件杂志,并删除了一个水夹式空白,将其放在Schunk Tandem ksp-lh中,加上160--在气动驱动的两爪夹具中。(夹具块具有8毫米的颌骨冲程和20 kN的夹紧力。)然后,ATC用切刀将握把单元交换为加工。

Once completed, the VMC swaps in the gripper that moves the machined parts to a station that rotates the workpieces 180 degrees. For the op. 20 work, the gripper places the indexed parts in the second two-jaw clamping block, a Tandem plus 160 with 3 mm of jaw stroke and 45 kN of clamping force. Finally, it loads a new blank into the op. 10 clamping block and the cycle continues. The clamping blocks are equipped with inductive monitoring of the jaw position to help ensure automation safety.

两者op。10和OP。20工作由两个后续的加工操作组成,以将空白切成三个标本。最后,在OP结束时。20,将三个标本分开,按包装将其推在一起,用抓地力去除,并放置在工件杂志中的定义位置。

“我们不需要任何特殊的自动化知识。”

To prevent excessive forces acting on the machine’s spindle during part loading, the spindle gripper uses a Schunk SW-B shank interface and compensation unit to adapt to inaccurate workpiece tolerances and positioning in six degrees of freedom. Before each machining cycle, the clamping devices, part indexing station and blank are cleared of chips and dirt using a cleaning device.

Increased Productivity and Flexibility

里奇特解释说:“使用夹具系统,索引设备以及ATC和工件杂志使我们的机器自动化,我们可以最大程度地提高机床的效率和可用空间。”“尽管过去,每个测试标本都是单独制造的,但现在可以同时加工三个样品,并减少了非生产性处理和设置时间。”

In order to remain as flexible as possible and produce one-off parts despite the integrated automation solution, Richter equipped the machine with a Schunk Vero-S NSL plus 200 clamping station. The modular, quick-change pallet system enables precise resetting of workpieces, clamping devices or other equipment outside the machine.

最后一次加工操作后,将三个标本分开,将其推在一起,用抓地力将其拆除,并将其放置在工件杂志中的定义位置。

对于Richter及其团队而言,这种精益自动化解决方案的最大好处是操作员的灵活性提高,并使该人执行其他任务的增值,而测试样品的加工则无人看管。他们还感谢该系统不需要任何特殊的机器人技术知识。“运营机器所需的一切都是我们运营商的编程技能;我们不需要任何特殊的自动化知识,可以自行管理该过程,并在必要时灵活地反应。”里奇特说。

Read: A Fitting Machining Process

Moreover, the Lean Automation system can be moved from one machine tool to another. Ultimately, it's about a gripper, a clamping system and a toolholder.

该公司的下一步已经开始重点:“一旦员工完全熟悉新系统并且一切正常,我们将实施下一阶段的自动化阶段,并生产出几种标本集,” Richter说。

RELATED CONTENT

制作微线

微线的生产可能具有挑战性,但是使用最合适的工具用于给定应用程序可以简化任务。

Skiving Long, Slender Parts with Tight Tolerances

Here's a look at one of the oldest and most efficient methods of screw machine production for parts that are long and slender, with close-diameter tolerances and finishes, or parts that require truly spherical radii.

A Guide to Insert Coating Processes and Materials

Few materials have had a greater impact on our economy and industrialized culture than cemented tungsten carbide.