A Leaner Shop With CNC

It was a tough decision, but once this company moved forward with the implementation of CNC, it quickly realized the benefits in production times, tolerances and finishes. Most important, though, was the added secondary-op capabilities that brought consistency to the personnel requirements of the shop.

Alfonso Garcia was not easily swayed. After all, he had been with the company for 20 years—10 as company president—and he had become quite accustomed to the unpredictable nature of the business, the constant personnel changes and the struggle to meet customer deadlines. He couldn’t see how incorporating CNC could alleviate the burning issues, and he couldn’t justify the cost or the time it would take to bring one of these machines into the mix. In fact, the pressures of deadlines were so immense, he couldn’t take the time to consider the possibilities.

Rite-On Screw Products Inc. (Irwindale, California) opened its doors in 1970 with two Brown & Sharpe 00G screw machines and two 2Gs. By 2005, it had amassed 18 Brown & Sharpes along with several Bridgeports and four Hardinge lathes for secondary operations. The shop was producing typical single-spindle work, mainly from brass and stainless, including parts for aerospace, medical, marine products and commercial appliance applications.

Featured Content

根据Alfonso的说法,这项工作继续进行,业务相当不错,但是对二次操作的需求不一致引起了管理人员人数的持续问题。他解释说:“如果合适的工作进来,我们需要在地板上多达18个人来保持所有机器运行并将产品送出门外。”“但是,如果我们所拥有的一切都是适合单主轴自动机构的长期工作,我们被迫躺下五到六个人,而不是付钱给他们什么都不做。When other jobs requiring secondary operations would come in later, we’d have to scramble to bring additional operators back in. Of course, the ones we had let go were usually no longer available, so we’d face still more challenges of finding quality employees and training.”

In 2004, Mike Colby, of Represents West (an independent sales representative for Ganesh Machinery), made his first call to Rite-On—a cold call that was not welcomed with open arms by Mr. Garcia. During the brief meeting, Mr. Colby tried to explain the benefits CNC could bring to the shop, but Mr. Garcia quickly dismissed him, saying, “We cannot increase our cycle time by taking in CNC lathes.”

大约一年以后,加西亚先生雇佣了他哥哥,Raymond, to handle accounts and to get involved in the day-to-day operations of the shop. Mr. Colby had been persistent in his efforts to explain to Alfonso that CNC machines would prove to be the key to Rite-On’s continued growth. Raymond was a recent college graduate and had a solid background in computers, so Alfonso thought he could provide a fair analysis of the machines’ potential at their shop.

经过进一步的讨论,Alfonso能够了解CNC机器的其他功能如何帮助公司。他制定了一项业务计划,以培养第一台Ganesh机器,这是一个四轴CNC Turn/Mill Center。商店的地板已经满足了棕色和夏普机器和储存量的零件,以等待二级操作,因此Alfonso的存储设施隔壁连接了该机器。他解释说:“我们不觉得我们有能力停止生产并拆除任何旧机器来安装新机器。”他们仍然不太确定自己正在进入什么,并且担心这些机器不会像预期的那样通过。“迈克告诉我们,周期时间很快,但是我们已经对那些站在机器出售中受益的人非常信任。”因此,他们尽可能保守地进行此举,以便在必要时保持期权倒退到旧机器上。

Ganesh培训师Gary Walts在Rite-On设施中只需要2天,以向Raymond展示如何充分利用机器。从那里开始,雷蒙德能够立即开始完成积累的二级操作工作。结果非常出色。

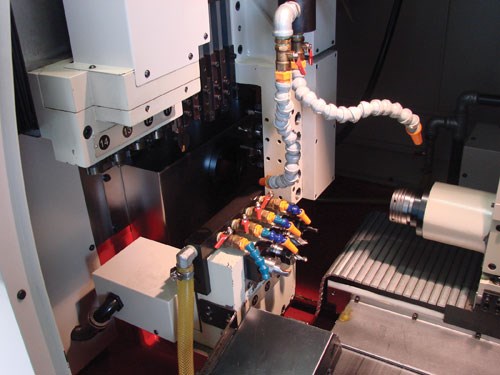

Within a matter of months, Rite-On began considering a second CNC machine. Alfonso and Raymond had quickly realized the consistency the step up to CNC had brought to the business, so they purchased a Cyclone 32 three-axis gang tool lathe with optional live tools. Less than a year later came the biggest commitment to CNC. Rite-On removed ten of its conventional machines, moved the Ganesh machines into the main facility and purchased yet another—a seven-axis dual-spindle mill/turn center.

显然,加入CNC机器一直是Rite-On业务的转折点。它为公司节省了很多时间和金钱,并为新业务打开了大门。雷蒙德说:“更快的生产,更紧密的公差和更好的饰面是一个很大的副作用。”“在螺丝机房屋中经常被忽视是处理零件的时间。显而易见的措施是机器订入金属的时间,棕色和夏普通常可以在几秒钟内敲开零件。但是,在准备下一个操作之前,将零件从铲斗中拉出并清洁底部并清洁它所需的时间又如何呢?它经过多次处理,通常需要在三个不同的操作后进行清洁。能够减少这段时间和这些费用是巨大的。”

但该公司购买了马赫的主要原因ines was to deal with the issue of labor. And that problem has certainly ironed itself out. Only seven employees now handle the workload that needed 18 people in the past. No longer do Raymond and Alfonso need to lay off employees when business slows down and then scramble to hire again later. And they are no longer reliant on the high-volume work that the Brown & Sharpes are so well suited for. Raymond explains, “We had gotten to a point where our profit margin was diminishing by costs related to re-hiring, training and excess handling. Now, the savings we’ve realized by carrying ten less employees for a year is roughly in line with the cost of all three of the CNC machines we purchased. And we’re far more productive and are able to take on work that we couldn’t produce before.”

—扩展机械

相关内容

Racing to High Tech Turning

赛车组件的制造商获得了更高的RPM,更快的急流和复杂的控制,并具有新的转弯机。

Multitasking Technology for Turn/Mill Lathes Evolves

From a few live tools on a turing center turret, turn-mill has developed into true multitasking machining.

瑞士型机器:不仅仅是车床

CNC Swiss-Type machines have more capability built in than ever before. Many of these capabilites can be accessed using attachments that increase the throughput of the machine tool, improve the quality of the work coming off the machine and reduce or eliminate the need for secondary operations even for very complex workpieces.